Liangchi Cooling Tower Fills Overview

Liangchi cooling tower fills are essential for cross-flow cooling towers, designed to maximize water-air contact for superior heat dissipation. Built for durability and efficiency, they cater to diverse industrial cooling needs.

Liangchi Cooling Tower Fills Specifications

Our fills are customizable in size, material, and thickness to meet your specific requirements. Contact us to discuss your needs for a tailored solution, including options for flame-retardant or antibacterial properties.

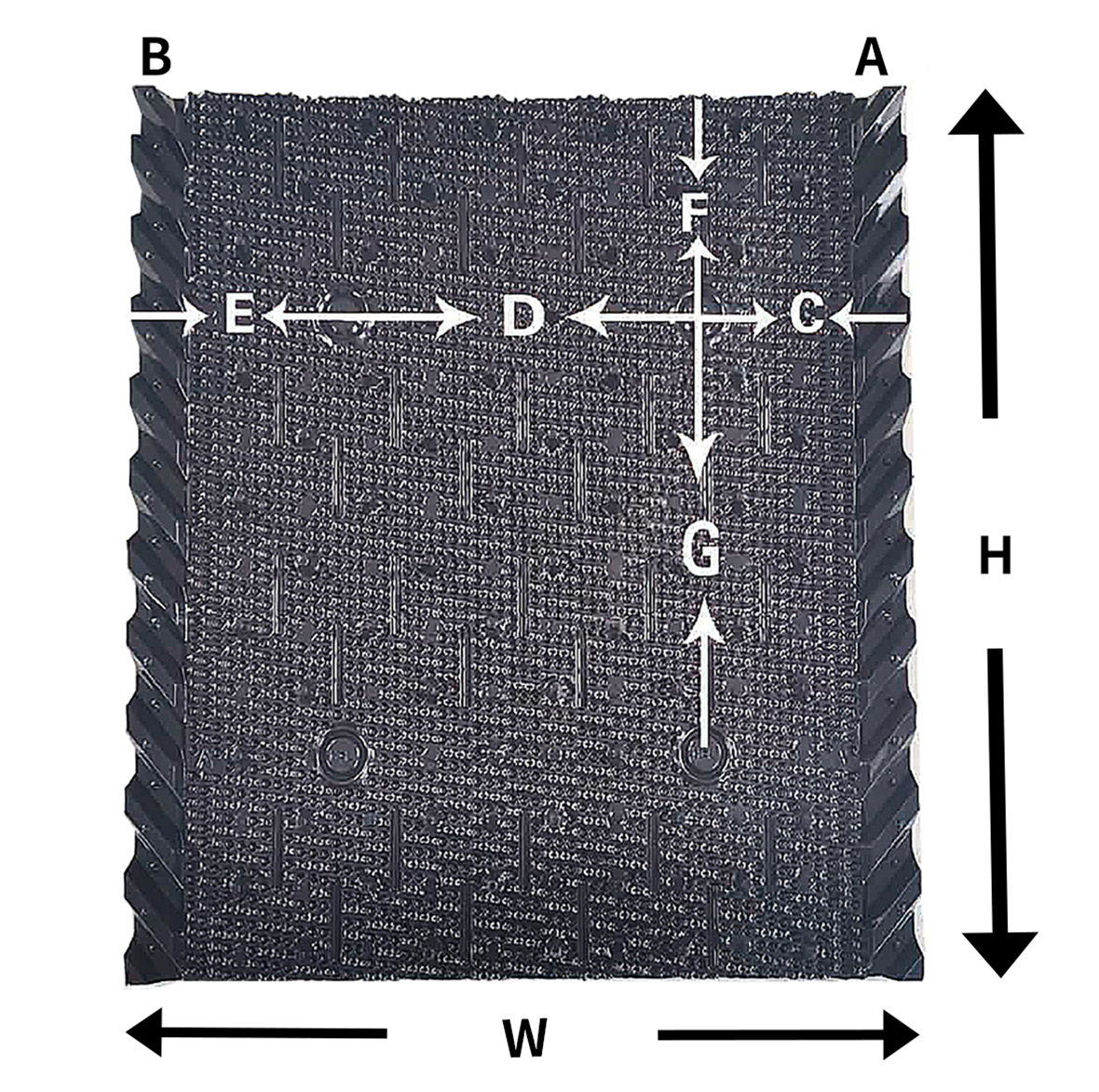

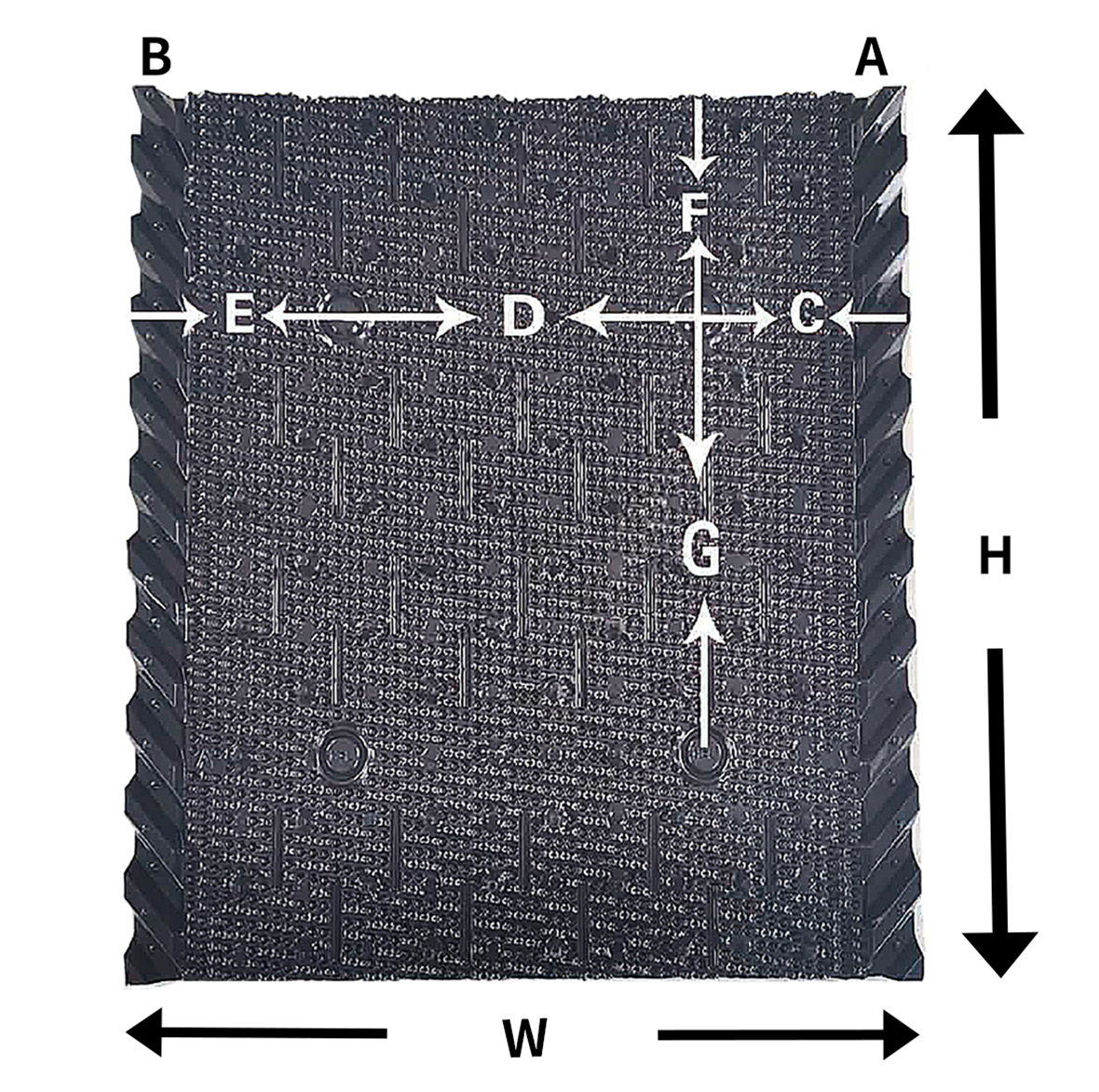

| W | H | A | B | C | D | E | F | G | Gap | Angle |

| 750 | G multiple | 55 | 55 | 200 | 350 | 200 | 200 | 400 | 20 | 90° |

| 950 | G multiple | 55 | 55 | 200 | 550 | 200 | 200 | 400 | 20 | 90° |

Material Options

Choose from PVC, PP, or CPVC for optimal durability and compatibility with your cooling system.

Thickness Options

Standard thickness of 0.32mm, with custom options available (minimum order: 3,000 pieces).

Customization Options for Liangchi Cooling Tower Fills

Custom logo (Min. order: 3,000 pieces)

Custom packaging (Min. order: 3,000 pieces)

Graphic customization (Min. order: 3,000 pieces)

When to Replace Liangchi Cooling Tower Fills

Maintaining cooling tower efficiency requires timely fill replacement. Key indicators include:

Aging and Wear

Contamination and Blockage

Structural Issues

Increased Resistance

Reduced Cooling Efficiency

Maintenance and Inspection

Environmental and Operating Conditions

Harsh conditions accelerate wear, requiring frequent checks.

Adjust replacement based on water quality and load.

Economic Considerations

Key Features of Liangchi Cooling Tower Fills

Material Characteristics

High-Quality PVC: Modified PVC offers corrosion and acid/alkali resistance for long-term use.

Flame Retardancy: Oxygen index ~42.7 reduces fire risk.

Wide Temperature Range: Operates from -50°C to 75°C.

Structural Design

Optimized Waveforms: Point wave, S wave, and chevron wave designs enhance cooling efficiency.

Low Ventilation Resistance: Minimizes fan energy use.

Easy Assembly: Glue-bonded or suspension designs simplify installation.

Thermal Performance

Additional Benefits

Long Service Life: Over 10 years with proper maintenance.

Energy-Saving: Reduces fan energy for eco-friendly operation.

Low-Noise: Minimizes operational noise and vibration.

Applications of Liangchi Cooling Tower Fills

Liangchi fills are used in industries including:

Chemical: Gas absorption and distillation.

Power: Cooling for power generation.

Steel: Metallurgical cooling.

HVAC: Air conditioning systems.

Environmental: Waste gas and water treatment.

Size Measurement for Liangchi Cooling Tower Fills

Accurate measurements ensure compatibility with your cooling tower. Refer to the diagram below for precise sizing.

Shipping and Packaging

Packaging

Packaged in bundles, on wooden pallets, or customized per your request.

Delivery Time

Delivered within 10 days.

Our Services for Liangchi Cooling Tower Fills

Pre-Sale Services

We provide product images, videos, quotations, and engineering drawings tailored to your needs. Factory visits are welcome.

Sale Services

Production schedule updates with photos.

24/7 support via phone, email, or online services.

On-site installation guidance and training available.

After-Sale Services

12-month warranty with ongoing support to ensure optimal performance.

About PT

With over 20 years of experience, PT is a trusted global supplier of high-quality cooling tower components. Our expertise in manufacturing and innovation ensures reliable, efficient solutions for industries worldwide. Request a Quote today to discover how we can meet your cooling needs.

Frequently Asked Questions (FAQ)

What is the purpose of Liangchi cooling tower fills?

Liangchi cooling tower fills increase the contact area between water and air, enhancing heat dissipation for efficient cooling in cross-flow cooling towers.

How often should cooling tower fills be replaced?

Replace every 5–8 years with regular maintenance, or 2–3 years without, depending on wear, contamination, or reduced efficiency.

What materials are available for Liangchi cooling tower fills?

Options include PVC, PP, and CPVC, with flame-retardant or antibacterial properties available.

Can I customize Liangchi cooling tower fills?

Yes, customization options include logos, packaging, and graphics with a minimum order of 3,000 pieces.

What industries use Liangchi cooling tower fills?

They are used in chemical, power, steel, HVAC, and environmental applications for efficient cooling.

How do I measure cooling tower fills for replacement?

Refer to our size measurement guide (see image above) to ensure accurate dimensions for your cooling tower.

What is the delivery time for Liangchi cooling tower fills?

Orders are typically delivered within 10 days.

How can I ensure optimal performance of cooling tower fills?

Regular inspections every 1–2 years and proper water quality management extend fill lifespan and maintain efficiency.

Why Choose Liangchi Cooling Tower Fills?

Premium Quality: Imported raw materials ensure durability.

Competitive Pricing: Flexible pricing for market needs.

Expertise: 20+ years in cooling tower solutions.

Superior Service: Comprehensive support with a 12-month warranty.