The cooling tower filler is one of the core components in the cooling tower, and its main function is to increase the contact area between water and air and improve the heat dissipation effect of water. Cooling tower fill is a crucial component in cooling tower systems, directly impacting cooling efficiency and overall system performance. Regular inspection and maintenance of cooling tower fill are essential for ensuring the efficient operation of cooling systems. When fill shows signs of aging, wear, contamination, blockage, loosening, detachment, or reduced cooling efficiency, it should be replaced promptly to maintain stable system operation and efficient cooling.

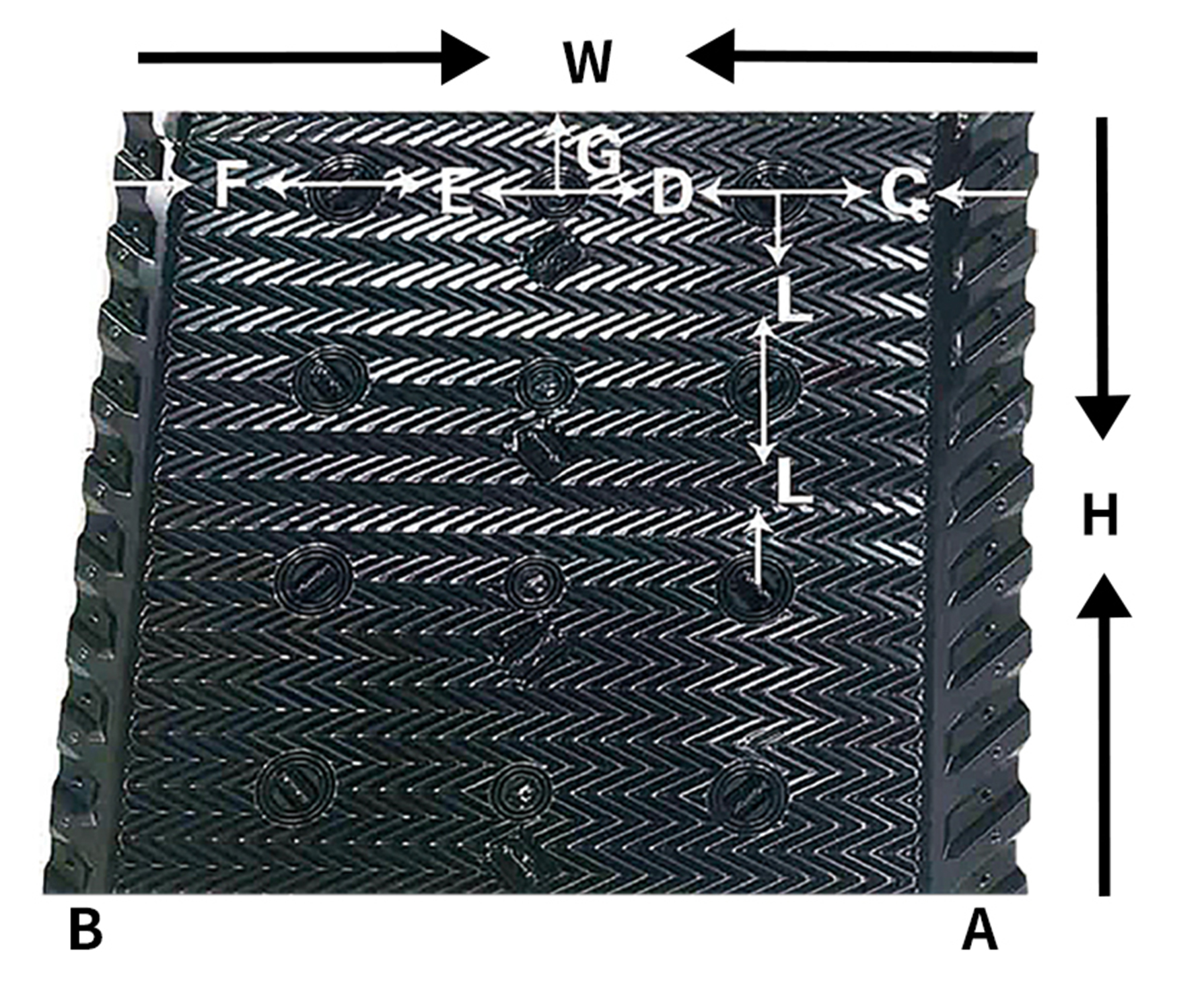

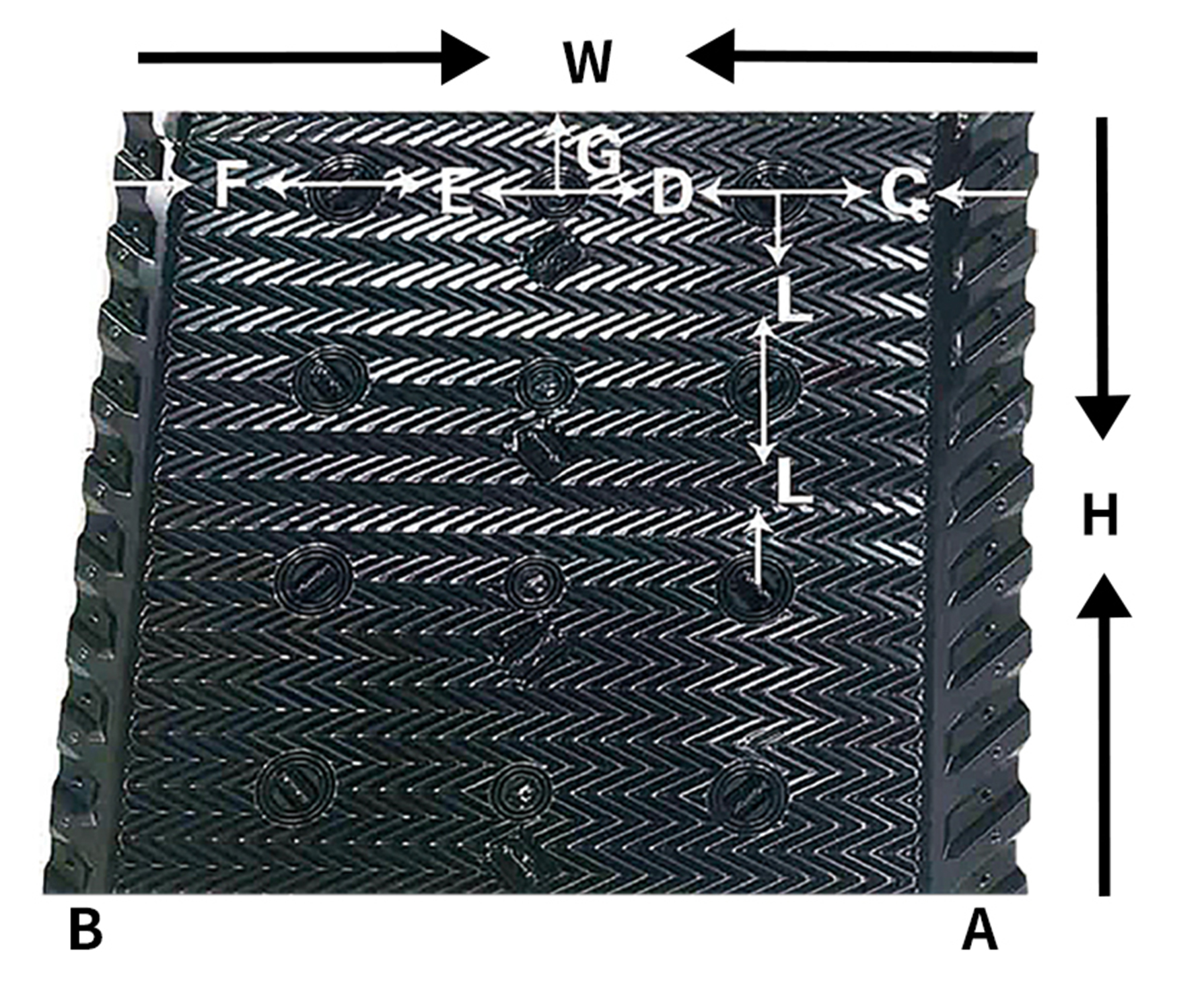

Splash Fill Cooling Tower Specification

There are different requirements for fillers, such as length and width, material or thickness, etc. Please tell us your detailed requirements so as to get the correct solution and provide a quotation. PT can cover all customer needs. Filler media can also be required in flame retardant or antibacterial performance.

W

| H | A | B | C | D

| E | F | G | L | Gap | Angle |

| 870 | L multiple | 60 | 90 | 320 | 200 | 200 | 250 | 100 | 200 | 19 | 90° |

Material:

PVC, PP, CPVC

Thickness:

0.32mm or customized (customized min order 3000 pieces)

Splash Fill Cooling Tower Customization options

Customized logo (Min. order: 3,000 pieces)

Customized packaging (Min. order: 3,000 pieces)

Graphic customization (Min. order: 3,000 pieces)

When To Replace Splash Fill Cooling Tower

Cooling tower fill is a crucial component in cooling tower systems, directly impacting cooling efficiency and overall system performance. Here are common situations and criteria for determining when to replace cooling tower fill:

1. Splash Fill Cooling Tower Aging and Wear

Surface Wear: Over time, the surface of the fill can wear out and age, reducing its performance and effectiveness.

Service Life: Generally, cooling tower fill should be replaced every 5 to 8 years under normal use. If proper maintenance is not performed, fill may need to be replaced every 2 to 3 years.

2. Splash Fill Cooling Tower Contamination and Blockage

Accumulation of Contaminants: During operation, cooling towers can accumulate various contaminants, such as sediment and sand, which can clog the fill, restricting water and air flow and affecting cooling efficiency.

Water Quality Issues: If the cooling water has poor quality, the fill may accumulate a significant amount of mud and bacteria, reducing heat dissipation capabilities. In such cases, fill replacement is necessary.

3. Splash Fill Cooling Tower Loosening and Detachment

Structural Damage: The internal structure of the fill may be affected by factors such as vibration, wind, and water impact, leading to loosening or detachment of the fill. This reduces the contact area between the fill and water/air, lowering cooling efficiency.

4. Splash Fill Cooling Tower Increased Resistance

Increased Airflow Resistance: Fill wear, blockage, and detachment can all lead to increased airflow resistance within the cooling tower. This can cause increased energy consumption, higher fan load, and may even affect the normal operation of the entire cooling system.

5. Splash Fill Cooling Tower Reduced Cooling Efficiency

Decreased Cooling Effectiveness: When the fill is severely damaged or aged, cooling efficiency can drop significantly, leading to equipment overloading and process anomalies.

High Water Temperature: If the cooling water is not sufficiently cooled, it may lead to excessively high water temperatures, affecting other equipment in the cooling system, such as condensers and pumps.

6. Splash Fill Cooling Tower Maintenance and Inspection

Regular Inspection: It is recommended to inspect the fill every 1 to 2 years to avoid sudden leaks due to aging.

Cleaning and Maintenance: Regular cleaning of the fill can extend its service life. However, if the fill is severely damaged or scaled, it should be replaced promptly.

7. Splash Fill Cooling Tower Environmental and Operating Conditions

Harsh Environments: If the cooling tower operates in high-temperature, high-humidity, or corrosive environments, the fill may wear out or become damaged more quickly. More frequent inspections and replacements may be necessary.

Operating Conditions: The frequency of fill replacement also depends on the operating conditions of the cooling tower, such as water temperature, water quality, and load.

8. Splash Fill Cooling Tower Economic Considerations

Reduced Product Yield: In some cases, even if product quality is not affected, a significant decrease in product yield may occur. In such instances, fill replacement should be considered to ensure economic efficiency, even if the fill appears undamaged.

Splash Fill Cooling Tower Features

The Features of Splash Fill Cooling Tower

Splash fill cooling towers are designed to enhance the cooling process by breaking water into smaller droplets and increasing the contact area between water and air. Here are the key features of splash fill cooling towers:

1. Splash Fill Cooling Tower Water Distribution and Contact

-

Increased Water Surface Area: The splash fill design uses multiple layers of slats or bars to break the water into smaller droplets. This increases the surface area of water exposed to air, enhancing evaporation and heat transfer.

-

Redistribution of Water: The water is redistributed at each level of the splash bars, making the system more forgiving of poor initial water distribution caused by clogged or missing nozzles.

2. Splash Fill Cooling Tower Efficiency and Performance

-

High Cooling Efficiency: The increased contact area and time between water and air lead to higher cooling efficiency. This is particularly beneficial in applications where large volumes of water need to be cooled.

-

Forgiving of Poor Water Quality: Splash fill towers are more tolerant of dirty water and debris. The splashing action helps separate dirt and debris from the water, making it suitable for industries with poor water quality, such as mining and chemical processing.

3. Splash Fill Cooling Tower Maintenance and Durability

-

Easy Maintenance: The open construction of splash fill towers allows for easy visual inspection and maintenance. General maintenance can often be performed with simple visual checks.

-

Long Service Life: Modern splash fills are made from durable materials like PVC, which can withstand harsh operating conditions and have a long service life.

4. Splash Fill Cooling Tower Structural and Operational Advantages

-

Stable Support Systems: Splash fill towers require stable support systems to maintain the level configuration of the splash bars. This ensures uniform water flow and prevents performance degradation.

-

Adaptability to Environment: Splash fill towers are ideal for dusty or wooded environments where debris might enter the system. They can also handle heavy ice loads in cold climates.

5. Splash Fill Cooling Tower Applications

-

Ideal for Dirty Water Applications: Splash fill towers are particularly suitable for industries that produce poor-quality water, such as food processing, steel production, paper processing, and hydrocarbon processing.

-

Versatile Use: They are commonly used in crossflow cooling towers, where the full-height air inlet face and open nature of the fill allow for easy inspection and maintenance.

6. Splash Fill Cooling Tower Comparison with Film Fill

Splash Fill Cooling Tower Conclusion

Splash fill cooling towers are designed to maximize the contact between water and air through the use of slats or bars that break water into smaller droplets. This design enhances cooling efficiency, makes the system more tolerant of poor water quality, and simplifies maintenance. They are particularly suitable for applications where water quality is an issue or where the environment is dusty or wooded.

Splash Fill Cooling Tower Size Measurement

Please measure the following data for the quality and reliability requirements of your maintenance cooling tower or maintenance project to adapt to the design of cooling tower filling or components.

Splash Fill Cooling Tower Application

The application range of cooling tower PVC fills is: Industrial water cooling,Air compressor, Aluminum profile processing, Steam turbine, Power generation, Tannery, Electric furnace, Freezing Series, Air conditioning cooling system

Splash Fill Cooling Tower Shippment

Packing:

In bundle,wooden pallet or as your request.

Delivery time:

With in 10 days.

Selling units:

Single item.

Our Services of Splash Fill Cooling Tower

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.