EBARA Cooling Tower Filler Overview

The EBARA cooling tower filler is a vital component designed to maximize water-air contact, enhancing heat dissipation efficiency in cooling towers. Available in widths of 950mm and 1250mm, it is engineered for durability, easy maintenance, and optimal performance in various industrial applications.

EBARA Cooling Tower Filler Specifications

Customizable to meet specific requirements, EBARA fillers are available in various lengths, widths, materials, and thicknesses. Options include flame-retardant or antibacterial properties. Contact us with your needs for a tailored solution and quotation.

| Width (mm) | Height (mm) | Gap (mm) | Angle |

| 950 | 950 | 20 | 90° |

| 1250 | 950 | 20 | 90° |

Material Options

Available in PVC, PP, or CPVC for durability and compatibility.

Thickness Options

Standard thickness of 0.32mm, customizable with a minimum order of 3,000 pieces.

Customization Options for EBARA Cooling Tower Filler

Custom logo (Min. order: 3,000 pieces)

Custom packaging (Min. order: 3,000 pieces)

Graphic customization (Min. order: 3,000 pieces)

Key Features of EBARA Cooling Tower Filler

Structural and Design Features

Integral Suspension Design: Corrugated patterns with a modified formula enhance strength and ease of cleaning.

Modular Structure: Facilitates flexible installation and quick replacement, reducing downtime.

Optimized Corrugated Design: Increases water-air contact area and improves water flow for enhanced cooling efficiency.

Material and Performance Features

High-Quality PVC: Offers corrosion, aging, and UV resistance, suitable for 50°C to 68°C temperatures.

Chemical Corrosion Resistance: Enhanced with anti-aging and flame-retardant properties for harsh industrial environments.

Lightweight and High Strength: Thickness of 0.30mm–0.45mm reduces weight while maintaining durability.

Cooling Effectiveness

High-Efficiency Heat Exchange: Optimized design ensures uniform water film distribution for superior cooling.

Low Resistance: Reduces airflow resistance, lowering fan energy consumption.

Uniform Water Distribution: Prevents localized overheating, maximizing performance.

Installation and Maintenance

Convenient Installation: Adhesive assembly and flat design simplify transport and setup.

Easy Maintenance: Smooth surfaces resist dirt, reducing cleaning effort.

Long Service Life: Lasts over 5 years with aging and UV resistance.

Applications of EBARA Cooling Tower Filler

EBARA cooling tower fillers are versatile, used in industries such as:

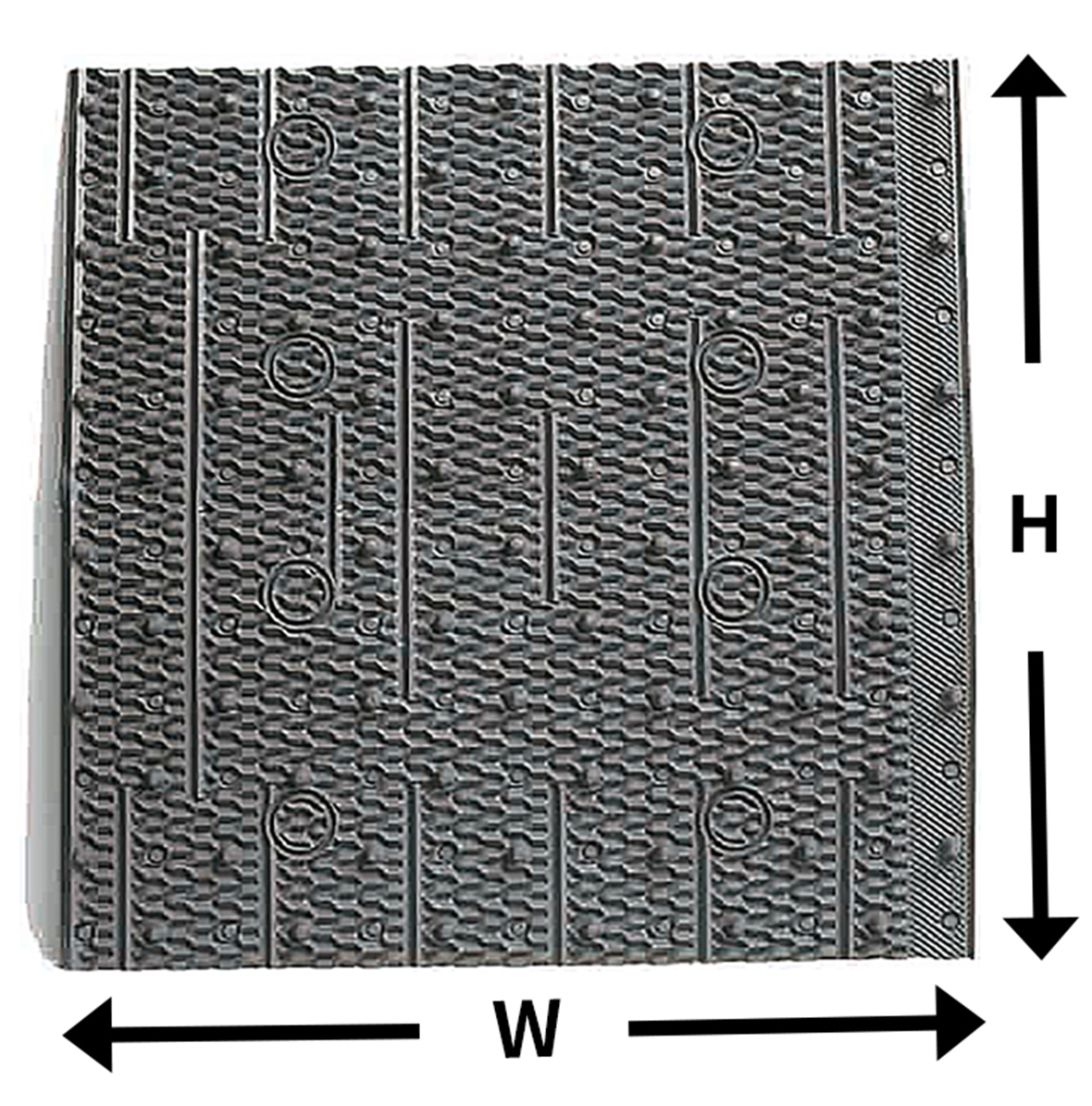

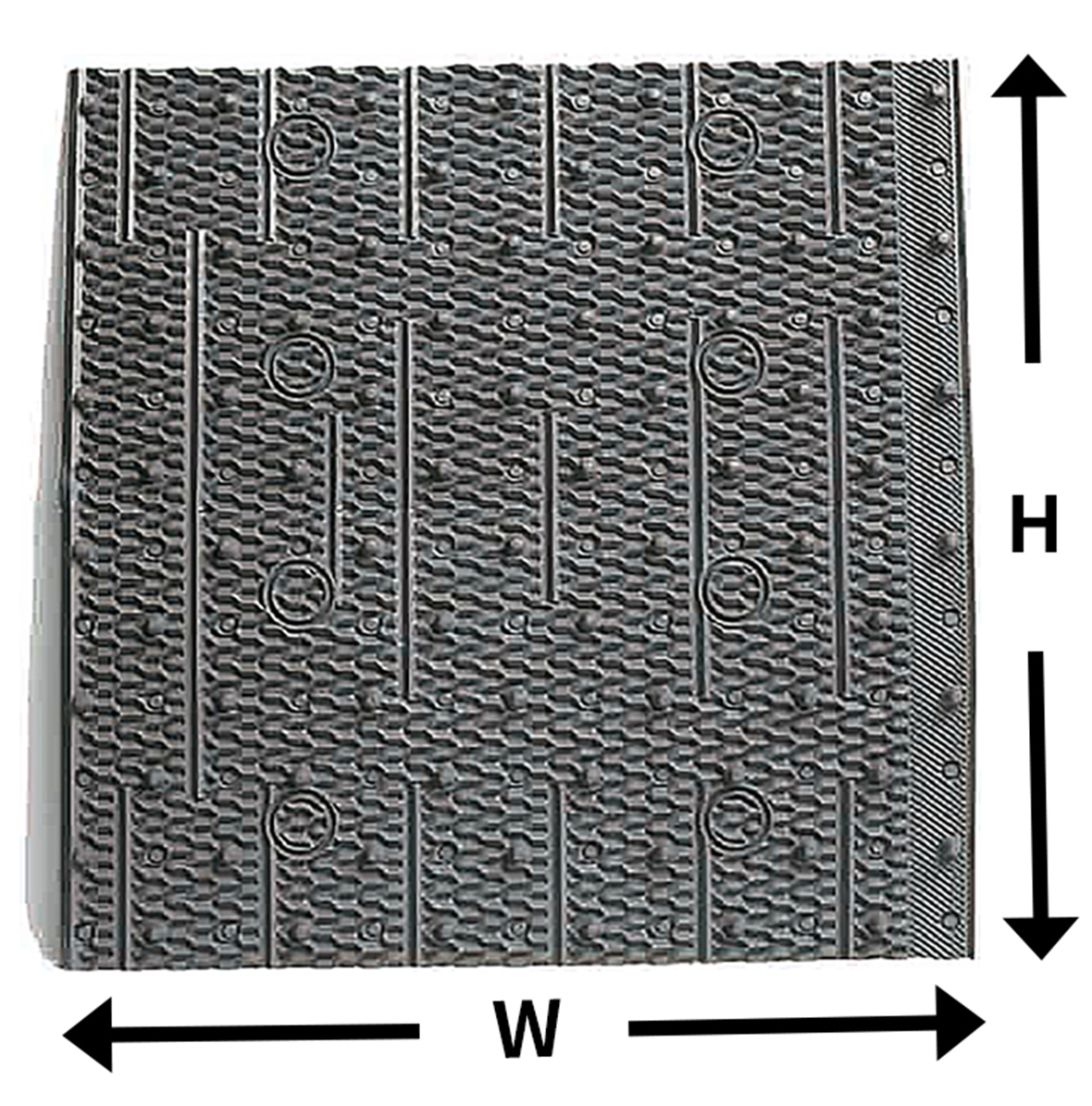

Size Measurement for EBARA Cooling Tower Filler

Accurate measurements ensure compatibility with your cooling tower. Refer to the diagram below for precise sizing.

Packaging and Shipping

Packaging

Packaged in bundles, on wooden pallets, or customized per request.

Delivery Time

Shipped within 10 days.

Selling Units

Available as single items.

Our Services for EBARA Cooling Tower Filler

Pre-Sale Services

We provide product images, videos, quotations, and engineering drawings tailored to your needs. Factory visits are welcome.

Sale Services

Production schedule updates with photos.

24/7 support via phone, email, or online services.

On-site installation guidance and training available.

After-Sale Services

12-month warranty with ongoing support to ensure optimal performance.

About PT

With over 20 years of experience, PT is a trusted global supplier of cooling tower components. Our expertise ensures high-quality, reliable solutions for industries worldwide. Request a Quote to explore how we can meet your cooling needs.

Frequently Asked Questions (FAQ)

What is the function of EBARA cooling tower filler?

It increases water-air contact to enhance heat dissipation in cooling towers.

What materials are used for EBARA cooling tower fillers?

PVC, PP, or CPVC, with optional flame-retardant or antibacterial properties.

Can EBARA fillers be customized?

Yes, logos, packaging, and graphics can be customized with a minimum order of 3,000 pieces.

What is the lifespan of EBARA cooling tower fillers?

Over 5 years with proper maintenance, thanks to UV and corrosion resistance.

What industries use EBARA cooling tower fillers?

Chemical, power, metallurgy, HVAC, data centers, and more.

How do EBARA fillers improve cooling efficiency?

Optimized corrugated design and uniform water distribution enhance heat exchange.

How are EBARA fillers installed?

Using adhesive assembly, with modular design for easy trimming and setup.

What is the delivery time for EBARA fillers?

Orders are delivered within 10 days.

Why Choose PT for EBARA Cooling Tower Filler?

Premium Quality: Made with imported raw materials for durability.

Competitive Pricing: Flexible pricing tailored to market demands.

Expertise: Over 20 years of experience in cooling tower solutions.

Superior Service: Comprehensive support with a 12-month warranty.