The cooling tower filler is one of the core components in the cooling tower, and its main function is to increase the contact area between water and air and improve the heat dissipation effect of water. Cooling tower fill is a crucial component in cooling tower systems, directly impacting cooling efficiency and overall system performance. Regular inspection and maintenance of cooling tower fill are essential for ensuring the efficient operation of cooling systems. When fill shows signs of aging, wear, contamination, blockage, loosening, detachment, or reduced cooling efficiency, it should be replaced promptly to maintain stable system operation and efficient cooling.

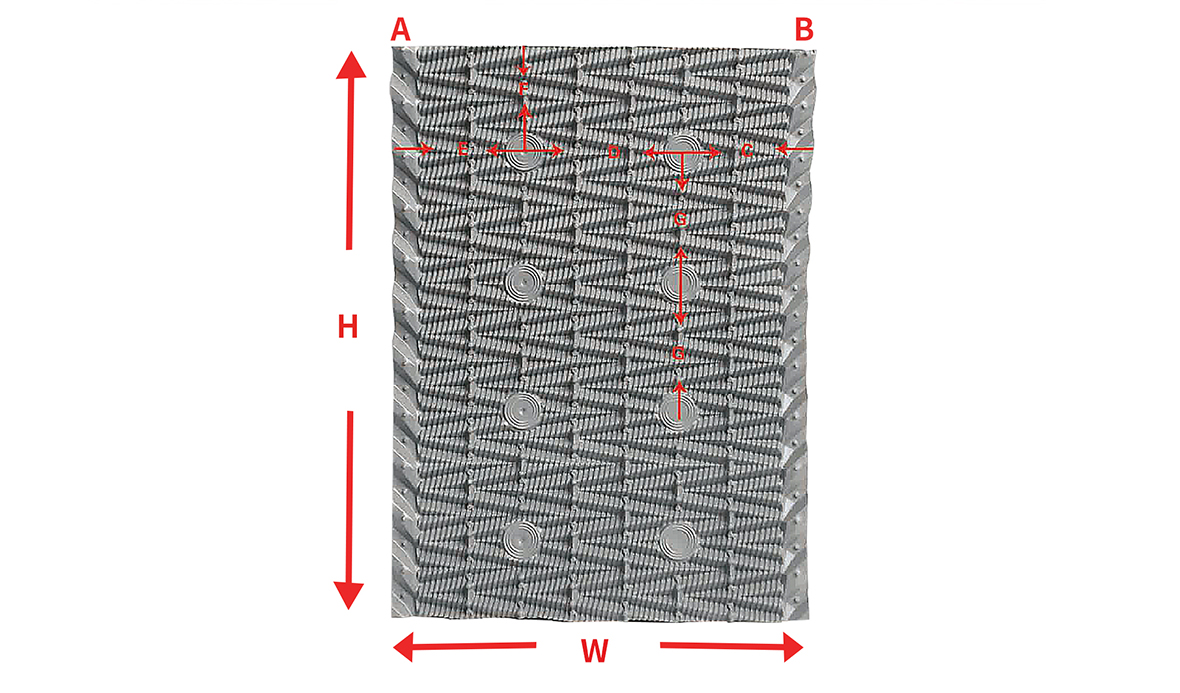

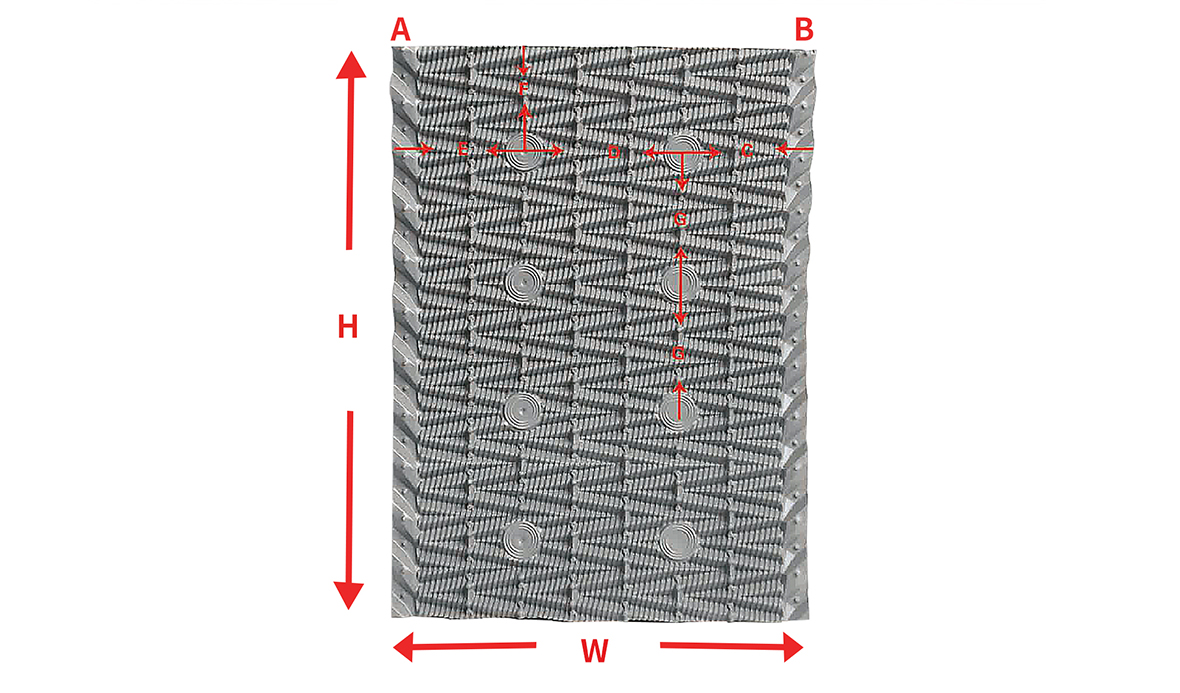

Kingsun PVC Cross Flow Cooling Tower Fills Supplier Specification

There are different requirements for fillers, such as length and width, material or thickness, etc. Please tell us your detailed requirements so as to get the correct solution and provide a quotation. PT can cover all customer needs. Filler media can also be required in flame retardant or antibacterial performance.

| W | H | A | B | C | D | E | F | G | Gap | Angle |

| 800 | G multiple | 55 | 55 | 250 | 300 | 250 | 200 | 250 | 20 | 90° |

| 1000 | G multiple | 55 | 55 | 250 | 500 | 250 | 200 | 250 | 20 | 90 |

Material:

PVC, PP, CPVC

Thickness:

0.32mm or customized (customized min order 3000 pieces)

Kingsun PVC Cross Flow Cooling Tower Fills Supplier Customization options

Customized logo (Min. order: 3,000 pieces)

Customized packaging (Min. order: 3,000 pieces)

Graphic customization (Min. order: 3,000 pieces)

Kingsun PVC Cross Flow Cooling Tower Fills Supplier Features

Kingsun PVC Cross Flow Cooling Tower Fills Supplier

Kingsun PVC Cross Flow Cooling Tower Fills Supplier is a key component in cooling towers designed to enhance cooling efficiency. It increases the contact area between air and water, extends the retention time of water within the fills, and thereby achieves efficient heat exchange. Below are the detailed features of Kingsun PVC Cooling Tower Fills Supplier:

1. Kingsun PVC Cross Flow Cooling Tower Fills Supplier Structural and Design Features

-

Water and Air Flow Direction

The design of Kingsun PVC Cross Flow Cooling Tower Fills allows water to flow downward from the top of the tower, while air enters horizontally from the sides. The perpendicular flow of water and air maximizes the contact area between the two, enhancing cooling efficiency.

-

Packing Shape and Arrangement

Crossflow fills typically features corrugated or honeycomb structures. These structures effectively increase the surface area of the water, while also reducing the resistance to air flow. The corrugated design of the packing prevents water from falling directly and instead forms a film along the surface of the packing, further improving cooling performance.

-

Modular Design

Crossflow fills usually adopts a modular design, which facilitates installation and maintenance. Modular packing can be flexibly combined according to the size and shape of the cooling tower, ensuring a perfect match between the fills and the cooling tower.

2. Kingsun PVC Cross Flow Cooling Tower Fills Supplier Material and Performance Features

-

Corrosion Resistance

Crossflow fills is typically made from materials such as polyvinyl chloride (PVC) or polypropylene (PP), which are highly resistant to corrosion. These materials can withstand the erosion of acids, alkalis, and salts, making them suitable for various water quality conditions. This corrosion resistance not only ensures a long service life but also reduces maintenance costs.

-

Lightweight Design

The use of lightweight materials means that the fills has a low specific gravity, reducing the overall weight of the cooling tower and the load on its support structure. This design not only facilitates installation and maintenance but also lowers the construction costs of the cooling tower.

-

Temperature Resistance

The temperature range that crossflow fills can withstand is typically between 50°C and 68°C, allowing it to operate stably under various climatic conditions.

3. Kingsun PVC Cross Flow Cooling Tower Fills Supplier Heat Transfer and Resistance Characteristics

-

Efficient Heat Exchange

By increasing the contact area between water and air, crossflow packing significantly enhances heat transfer efficiency. Its corrugated structure allows water to form a film, further increasing the contact time between air and water, thereby improving cooling performance.

-

Low Resistance Design

The structural design of crossflow fills effectively reduces the resistance to air flow, lowering the energy consumption of the cooling tower. Compared to counterflow fills, crossflow packing offers lower resistance and more uniform air distribution.

-

Uniform Water Distribution

Crossflow fills ensures that cooling water is evenly distributed across the surface of the fills. This uniform water distribution not only improves cooling efficiency but also reduces the risk of fills blockage.

4. Kingsun PVC Cross Flow Cooling Tower Fills Supplier Maintenance and Cleaning Features

-

Easy Cleaning and Maintenance

The smooth surface of crossflow fills makes it less likely to adhere to dirt, facilitating cleaning and maintenance. This design reduces the risk of blockage and scaling in the cooling tower, maintaining good working conditions.

-

Modular Replacement

Thanks to its modular design, fills replacement and maintenance are more convenient. When fills is damaged or blocked, modules can be quickly replaced to minimize downtime.

-

Regular Maintenance Recommendations

It is recommended that crossflow fills be cleaned at least once a year to ensure its performance. During cleaning, high-pressure water guns should be avoided to prevent damage to the fills.

5. Kingsun PVC Cross Flow Cooling Tower Fills Supplier Application Scenarios

-

Industrial Cooling

Crossflow fills is widely used in industries such as power, chemical, petroleum, and metallurgy, meeting the cooling requirements of various industrial environments. Its energy-efficient features make it an ideal choice for modern industrial cooling systems.

-

Air Conditioning Systems

In air conditioning systems, crossflow fills effectively reduces the temperature of cooling water, improving the efficiency of air conditioning systems. Its low noise and energy consumption make it particularly suitable for use in residential areas and commercial buildings.

6. Kingsun PVC Cross Flow Cooling Tower Fills Supplier Technical Parameters

-

Fills Height

The height of crossflow fills is typically designed according to specific working conditions, generally ranging from 1.2 meters to 1.8 meters. The selection of fills height should be optimized based on the design requirements and cooling needs of the cooling tower.

-

Packing Material

Mainly made from materials such as polyvinyl chloride (PVC) or polypropylene (PP). These materials not only offer strong corrosion resistance but also have a long service life.

-

Service Life

Under normal operating conditions, the design life of crossflow fills is more than 10 years. Regular maintenance and cleaning can further extend the service life of the fills.

7. Kingsun PVC Cross Flow Cooling Tower Fills Supplier Installation and Usage Precautions

-

Installation Method

Crossflow fills is installed in a suspended manner, ensuring a tight fit with the cooling tower. The installation should ensure that water is evenly distributed to avoid local blockages.

-

Uniform Water Distribution

Cooling water should be evenly distributed on the top of the fills using a combination of gravity sump and spray nozzles. Nozzles with a large diameter and low clogging risk should be selected to ensure long-term stable operation.

-

Drift Rate Control

The water collection system should have high collection efficiency and low air resistance, with a drift rate of less than 0.001%. This not only reduces the waste of cooling water but also lowers the operating costs of the cooling tower.

Summary

Kingsun PVC Cooling Tower Fills, with its excellent structural design, material performance, heat transfer characteristics, and maintenance convenience, has been widely applied in the industrial cooling field. Its energy-efficient features make it an ideal choice for modern industrial cooling systems. By properly selecting and maintaining crossflow packing, the operating efficiency of cooling towers can be significantly improved, reducing energy consumption and maintenance costs.

Kingsun PVC Cross Flow Cooling Tower Fills Supplier Size Measurement

Please measure the following data for the quality and reliability requirements of your maintenance cooling tower or maintenance project to adapt to the design of cooling tower filling or components.

Kingsun PVC Cross Flow Cooling Tower Fills Supplier Application

The application range of cooling tower PVC fills is: Industrial water cooling,Air compressor, Aluminum profile processing, Steam turbine, Power generation, Tannery, Electric furnace, Freezing Series, Air conditioning cooling system

Kingsun PVC Cross Flow Cooling Tower Fills Supplier Cooling Tower Shipment

Packing:

In bundle,wooden pallet or as your request.

Delivery time:

With in 10 days.

Selling units:

Single item.

Our Service Of Kingsun PVC Cross Flow Cooling Tower Fills Supplier Cooling Tower

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.