The film type fill cooling tower is one of the core components in the cooling tower, and its main function is to increase the contact area between water and air and improve the heat dissipation effect of water.

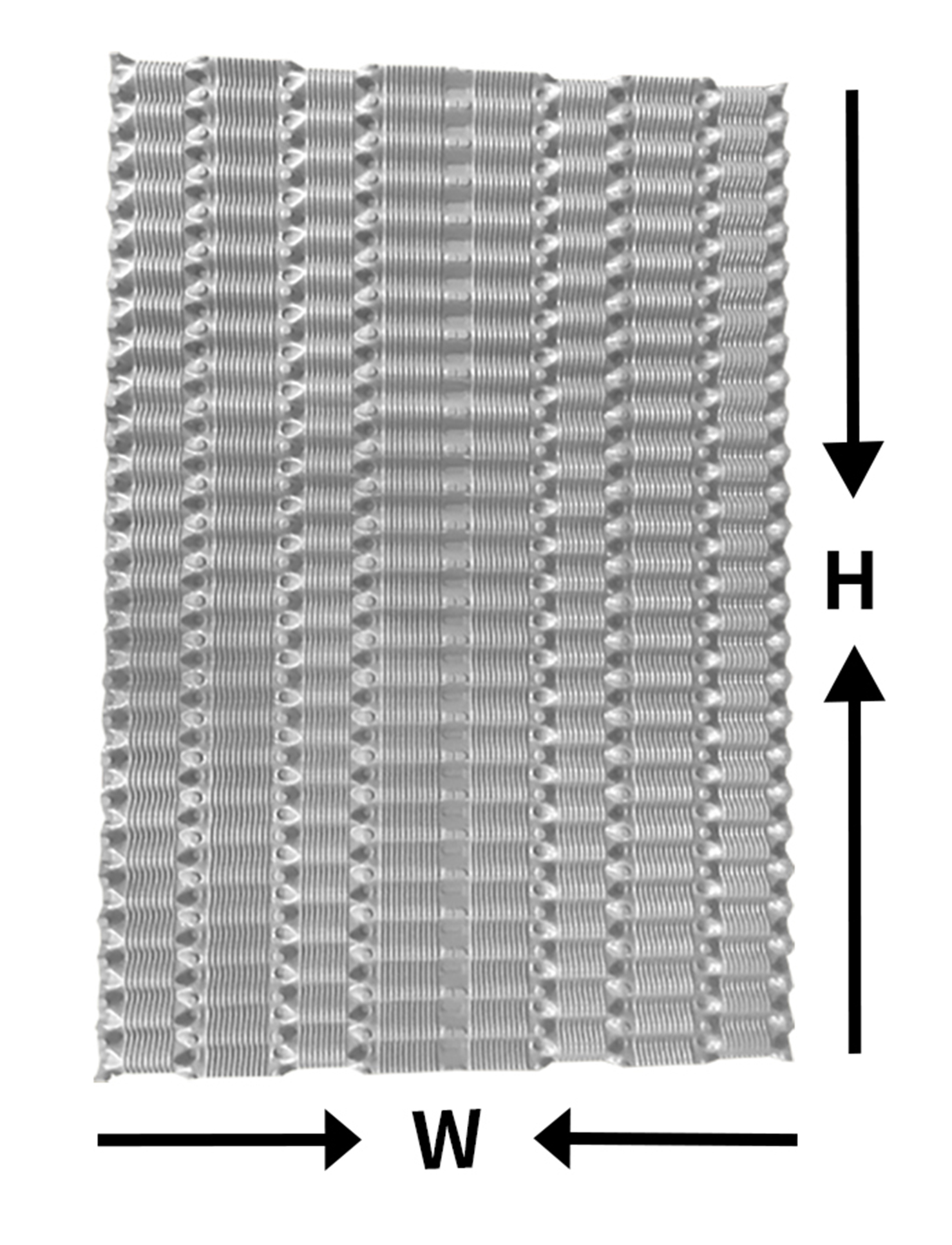

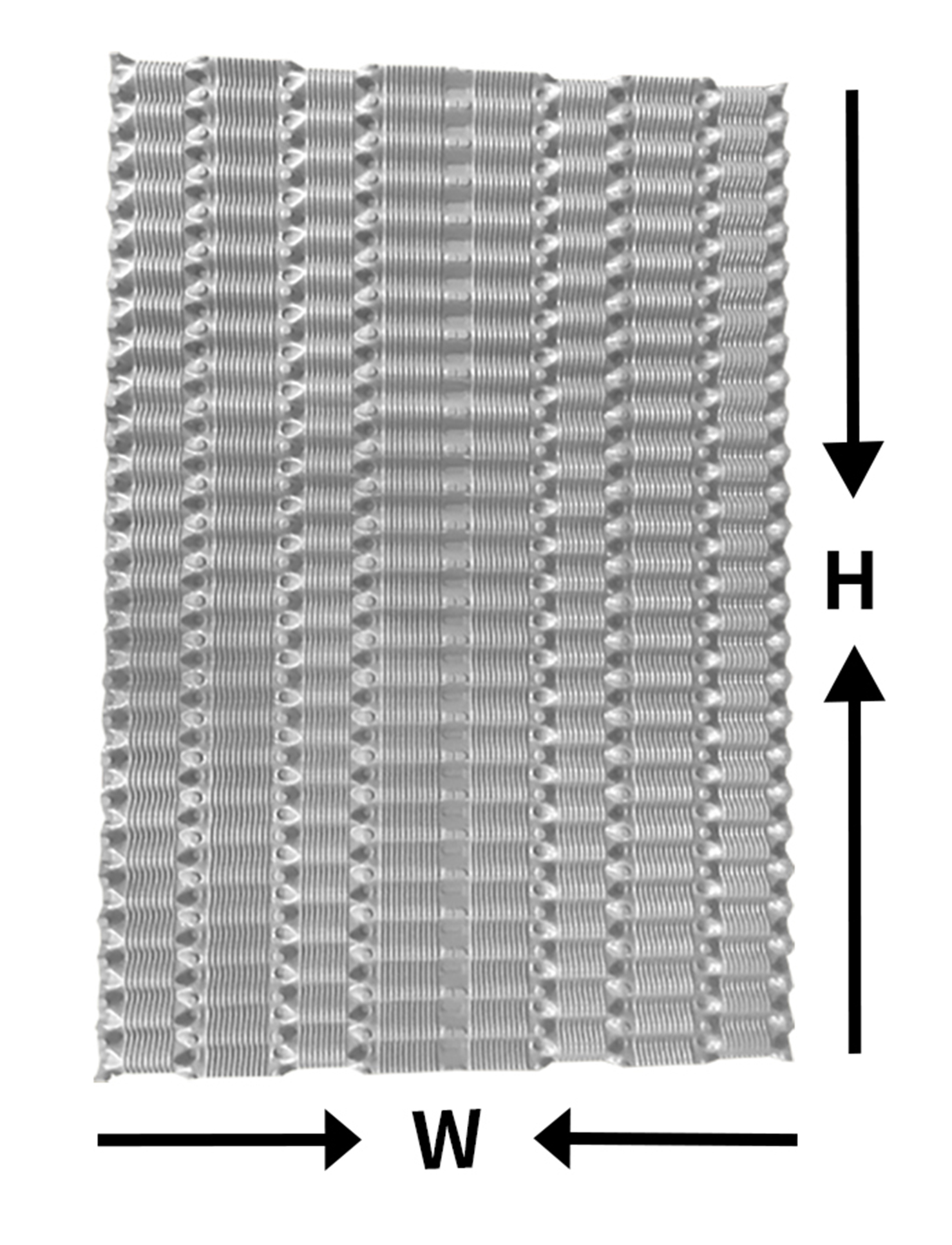

Film Type Fill Cooling Tower Specification

There are different requirements for film type fill cooling tower, such as length and width, material or thickness, etc. Please tell us your detailed requirements so as to get the correct solution and provide a quotation. PT can cover all customer needs. Filler media can also be required in flame retardant or antibacterial performance.

W

| H | Gap | Angle |

| 500 | Any | 20 | 90° |

| 1000 | Any | 20 | 90° |

Material:

PVC, PP, CPVC

Thickness:

0.32mm or customized (customized min order 3000 pieces)

Film Type Fill Cooling Tower Customization options

Customized logo (Min. order: 3,000 pieces)

Customized packaging (Min. order: 3,000 pieces)

Graphic customization (Min. order: 3,000 pieces)

How To Choose The Right Film Type Fill Cooling Tower

Selecting the appropriate cooling tower fill is crucial for ensuring the performance and efficiency of a cooling tower. Here are some important considerations and suggestions for choosing cooling tower fill:

1. Choose Film Type Fill Cooling Tower Based on Cooling Water Quality

-

Poor Water Quality: When the cooling water contains fibers or has a suspended solids concentration greater than 100mg/L, or there is a possibility of raw oil leakage, drip-type fill should be selected.

-

Good Water Quality: If the suspended solids concentration in the cooling water is less than 50mg/L and the water quality is well controlled, film-type fill is recommended.

-

Moderate Water Quality: When the suspended solids concentration is between 50mg/L and 100mg/L, drip-film hybrid fill is a better choice.

2. Choose Film Type Fill Cooling Tower Based on Cooling Tower Type

-

Counterflow Cooling Tower: The fill is typically arranged above the air inlet of the tower. Film-type or drip-film fill can reduce the total height and cost of the tower, making it a preferred choice for engineering design.

-

Crossflow Cooling Tower: The fill height is the same as the air inlet height of the tower, making it suitable for using drip-type fill with greater height. However, film-type or drip-film fill, which have no height limitations, can also be applied.

3. Choose Film Type Fill Cooling Tower Based on Inlet Water Temperature

-

Low Water Temperature: When the inlet water temperature does not exceed 45℃, modified polyvinyl chloride (PVC) fill performs best.

-

Moderate Water Temperature: For water temperatures between 45℃ and 60℃, chlorinated polyvinyl chloride (CPVC) or polypropylene (PP) fill is more heat-resistant.

-

High-Temperature Environment: When the water temperature exceeds 60℃, especially above 70℃, high-temperature-resistant materials such as aluminum alloy should be considered.

4. Choose Film Type Fill Cooling Tower Based on Fan Characteristics

The thermal performance and resistance characteristics of the fill need to match the fan characteristics. Under the same design conditions, the fill with the greatest cooling capacity should be chosen. Thermal performance is often accompanied by higher resistance, which needs to be considered in conjunction with the actual working air pressure and air density of the fan.

5. Choose Film Type Fill Cooling Tower Based on Fill Arrangement

-

Suspension Fill: When suspending fill in large cooling towers, the stability of the fill should be considered to avoid shaking. The assembly form of the fill should facilitate construction and daily maintenance.

-

Support Structure: When the fill blocks are directly supported on small beams, fill with a smaller width and lower air resistance should be selected. The design span of the support grating should be consistent with the support beams, and its corrosion resistance should match that of the fill.

6. Other Considerations When Choose Film Type Fill Cooling Tower

-

Corrosion Resistance: Fill exposed to air for a long time is prone to corrosion. Therefore, choosing fill with strong corrosion resistance is crucial.

-

Specific Surface Area: The larger the specific surface area, the greater the contact area between water and air, resulting in better cooling performance.

-

Permeability: Fill with good permeability can reduce air flow resistance, increase air flow, and thus improve cooling efficiency.

-

Environmental Friendliness: Choosing environmentally friendly fill can reduce the impact on the environment.

Conclusion When Choose Film Type Fill Cooling Tower

Selecting the right cooling tower fill requires a comprehensive consideration of factors such as cooling water quality, cooling tower type, inlet water temperature, fan characteristics, fill arrangement, as well as corrosion resistance, specific surface area, permeability, and environmental friendliness. Only by choosing the appropriate fill can the cooling tower achieve the best cooling effect, improve the efficiency and service life of the cooling tower.

How to Replace Film Type Fill Cooling Tower and the Benefits of Replacement

I. Steps to Replace Film Type Fill Cooling Tower

-

Preparation Before Film Type Fill Cooling Tower Replacement

-

Turn off the power supply to the cooling tower to ensure safety.

-

Prepare the necessary tools for replacement, such as wrenches, screwdrivers, and cleaning agents.

-

Have the new fill ready and check that its model matches the original equipment.

-

Removing the Old Film Type Fill Cooling Tower

-

Turn off the motor power and remove the pull bars from the cooling tower fill section.

-

Carefully remove the old fill from the support frame using tools, avoiding damage to the tower body and other components.

-

Clean up any garbage and residual fill fragments inside the tower.

-

Cleaning the Tower Body Before Film Type Fill Cooling Tower

-

Installing the New Film Type FillCooling Tower Replacement

-

According to the design requirements of the cooling tower, install the new fill layer by layer onto the support frame.

-

Ensure that the fill is securely installed and neatly arranged to achieve the best heat exchange effect.

-

When installing, pay attention to the spacing and number of fill layers to ensure that the fill is closely attached to the tower walls, columns, and beams, with a maximum gap of no more than 20mm.

-

After installation, restore the pull bars in the cooling tower fill section.

-

System Testing After Film Type Fill Cooling Tower Replacement

-

After the new fill is installed, conduct a system test to check for leaks or other issues.

-

If no problems are found, refill the cooling tower with cooling water and start it for a trial run.

-

Precautions After Film Type Fill Cooling Tower Replacement

-

During the construction process, welding operations above the fill are strictly prohibited. If necessary, fire prevention measures must be taken.

-

When installation, maintenance, or other work needs to be carried out on the fill, it must be done on a flat plate. Direct stepping on the fill is strictly prohibited.

II. Benefits of Replacing Film Type Fill Cooling Tower

-

Film Type Fill Cooling Tower Improved Cooling Efficiency

-

New fill can increase the contact area between water and air, thereby improving cooling efficiency and ensuring that the cooling tower achieves its designed cooling effect.

-

After replacing the fill, the cooling efficiency of the cooling tower can be significantly improved. For example, Luopu Tianshan Cement Company improved its cooling efficiency by 15% after replacing the fill.

-

Film Type Fill Cooling Tower Reduced Energy Consumption and Operating Costs

-

Film Type Fill Cooling Tower Extended Service Life of the Cooling Tower

-

Old fill may affect the performance of the cooling tower due to aging, damage, or blockage. Timely replacement of the fill can reduce wear on other components of the cooling tower and extend its service life.

-

Film Type Fill Cooling Tower Reduced Maintenance and Repair Frequency and Costs

-

After replacing the fill, the operation of the cooling tower becomes more stable, and the failure rate is significantly reduced, thereby reducing the frequency and costs of maintenance and repair.

-

Film Type Fill Cooling Tower Reduced Carbon Emissions

Film Type Fill Cooling Tower Size Measurement

Please measure the following data for the quality and reliability requirements of your maintenance cooling tower or maintenance project to adapt to the design of cooling tower filling or components.

Film Type Fill Cooling Tower Application

The application range of cooling tower PVC fills is: Industrial water cooling,Air compressor, Aluminum profile processing, Steam turbine, Power generation, Tannery, Electric furnace, Freezing Series, Air conditioning cooling system

Film Type Fill Cooling Tower Shipment

Packing:

In bundle,wooden pallet or as your request.

Delivery time:

With in 10 days.

Our Services of Film Type Fill Cooling Tower

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.