Cross flow film fills for cooling towers is one of the core components in the cooling tower, and its main function is to increase the contact area between water and air and improve the heat dissipation effect of water.

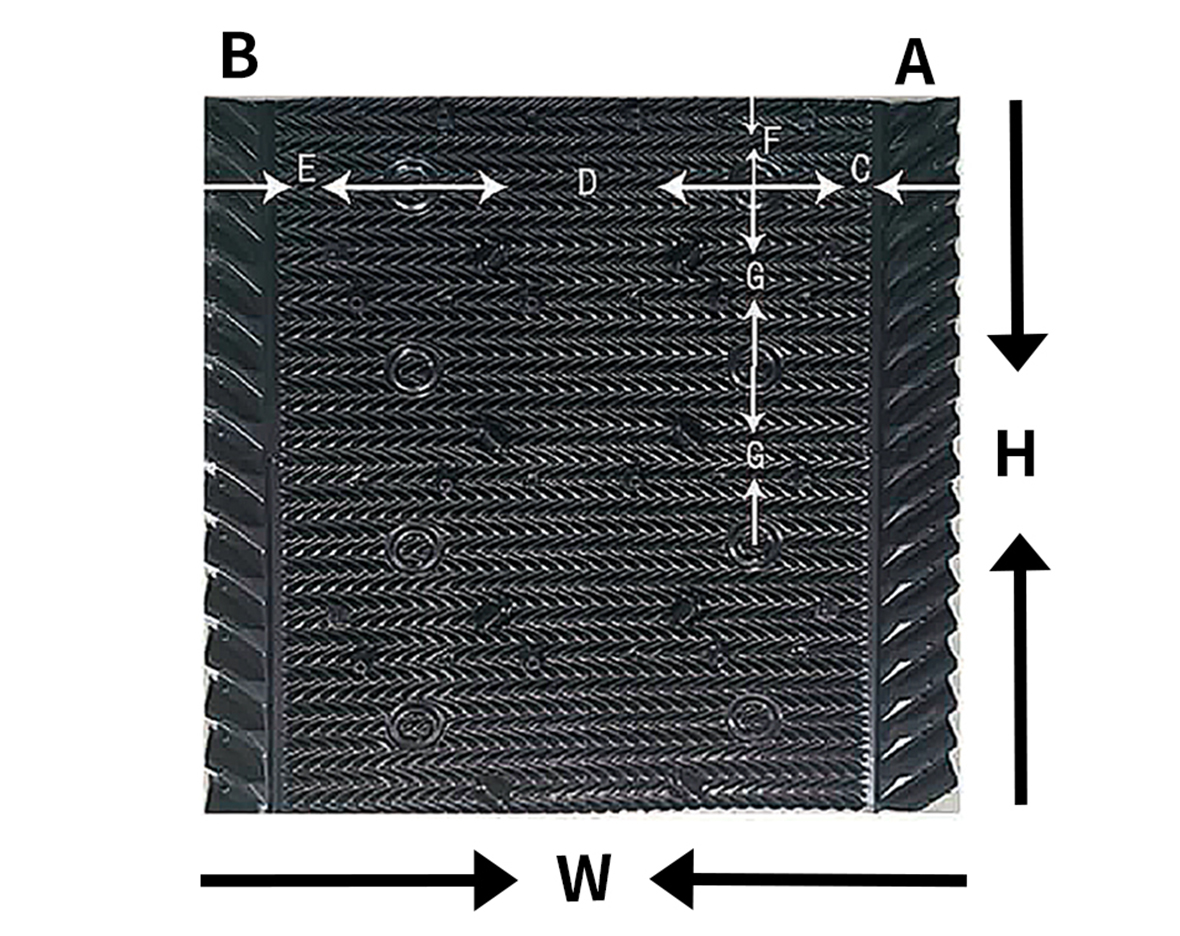

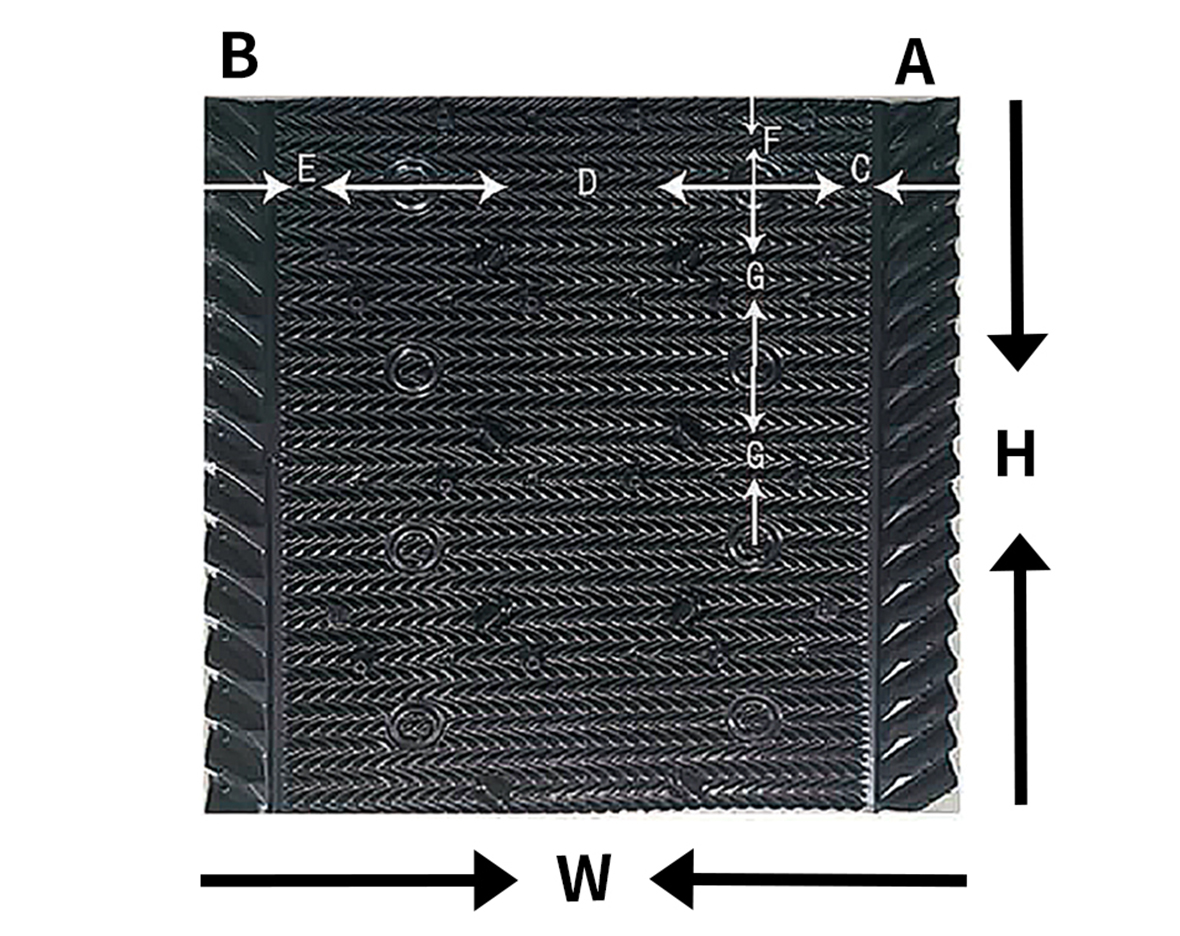

Cross Flow Film Fills For Cooling Towers Specification

There are different requirements for cross flow film fills for cooling towers, such as length and width, material or thickness, etc. Please tell us your detailed requirements so as to get the correct solution and provide a quotation. PT can cover all customer needs. Filler media can also be required in flame retardant or antibacterial performance.

W

| H | A | B | C | D | E | F | G | Gap | Angle |

| 920 | G multiple | 96 | 82 | 246 | 420 | 254 | 120 | 242 | 19 | 90° |

| 1120 | G multiple | 96 | 82 | 246 | 620 | 254 | 120 | 242 | 19 | 90° |

| 1320 | G multiple | 96 | 82 | 246 | 820 | 254 | 120 | 242 | 19 | 90° |

Material:

PVC, PP, CPVC

Thickness:

0.32mm or customized (customized min order 3000 pieces)

Cross Flow Film Fills For Cooling Towers Features

Vacuum molding with flame-retardant PVC material can improve the thermal performance of the filler by an average of 7.3% and prolong its service life.

Convenient inspection, no disassembly, and convenient cleaning.

Self-extinguishing PVC material is free from decay and biological erosion, and its applicable temperature is below 50℃.

Select products available with Mechanical Assembly technology.

Cross Flow Film Fills For Cooling Towers Customization options

Customized logo (Min. order: 3,000 pieces)

Customized packaging (Min. order: 3,000 pieces)

Graphic customization (Min. order: 3,000 pieces)

Signs That the Film Fills For Cooling Towers Needs Replacement

When it comes to maintaining the efficiency and performance of a cooling tower, recognizing the signs that indicate the need for fill replacement is crucial. Here are several key indicators that your cooling tower fill may need to be replaced:

-

Reduced Cooling Efficiency

If the cooling tower is not cooling the water as effectively as it used to, this could be a sign that the fill is clogged or damaged. This inefficiency can lead to higher operating costs and increased energy consumption.

-

Increased Energy Consumption

A cooling tower that is not functioning efficiently will require more energy to operate, which will be reflected in higher energy bills. If you notice an unexplained increase in your energy costs, it may be time to inspect and potentially replace the fill.

-

Visible Damage or Wear

Physical damage such as cracks, warping, or wear on the fill media is a clear indication that the fill is deteriorating and should be replaced. Additionally, if the support grid holding the fill is damaged, it can cause the fill to become misaligned or fall out of place.

-

Scaling and Fouling

Over time, minerals like calcium can accumulate on the fill media, creating scale deposits that reduce airflow and disrupt water distribution. This buildup can significantly impair the heat exchange process, decreasing the tower’s efficiency. If regular cleaning cannot remove the scale, replacement is necessary.

-

Uneven Water Distribution

If the fill media is clogged or damaged, water distribution becomes uneven. This can result in areas where water pools excessively, while other sections remain dry, reducing the overall effectiveness of the cooling process. Uneven water distribution can also lead to hot spots and reduced cooling capacity.

-

Increased Maintenance Frequency

If the cooling tower requires more frequent maintenance than usual, it may be a sign that the fill needs to be replaced. Frequent cleaning, repairs, or patching of the fill media can indicate that it is nearing the end of its service life.

-

Excessive Noise

Cooling towers typically generate some noise, but if you notice an increase in noise levels, especially during high load conditions, it could be due to worn-out fill media. This can be particularly noticeable if water is crashing against degraded fill sheets.

-

Water Buildup and Staining

When the fill media degrades, it can lead to water pooling and staining nearby systems. This is a sign that the fill is no longer effectively distributing water and needs to be replaced.

-

Foul Odors

Bacterial growth on the fill media can cause unpleasant odors. If you notice a strong, foul smell emanating from the cooling tower, it may be due to deteriorating fill media.

-

Corrosive Mineral Buildup

Minerals like rust and calcium carbonate can deposit on the fill media, attracting dirt and other pollutants. Over time, this can lead to corrosion and degradation of the fill media, necessitating replacement

How to Replace Cross Flow Film Fills For Cooling Towers and the Benefits of Replacement

I. Steps to Replace Cross Flow Film Fills For Cooling Towers

-

Preparation Before Replace Cross Flow Film Fills For Cooling Towers

-

Turn off the power supply to the cooling tower to ensure safety.

-

Prepare the necessary tools for replacement, such as wrenches, screwdrivers, and cleaning agents.

-

Have the new fill ready and check that its model matches the original equipment.

-

Removing the Old Cross Flow Film Fills For Cooling Towers

-

Turn off the motor power and remove the pull bars from the cooling tower fill section.

-

Carefully remove the old fill from the support frame using tools, avoiding damage to the tower body and other components.

-

Clean up any garbage and residual fill fragments inside the tower.

-

Cleaning the Tower Body Before Cross Flow Film Fills For Cooling Towers

-

Installing the New Cross Flow Film Fills For Cooling Towers

-

According to the design requirements of the cooling tower, install the new fill layer by layer onto the support frame.

-

Ensure that the fill is securely installed and neatly arranged to achieve the best heat exchange effect.

-

When installing, pay attention to the spacing and number of fill layers to ensure that the fill is closely attached to the tower walls, columns, and beams, with a maximum gap of no more than 20mm.

-

After installation, restore the pull bars in the cooling tower fill section.

-

System Testing After Cross Flow Film Fills For Cooling Towers Peplacement

-

After the new fill is installed, conduct a system test to check for leaks or other issues.

-

If no problems are found, refill the cooling tower with cooling water and start it for a trial run.

-

Precautions After Cross Flow Film Fills For Cooling Towers Peplacement

-

During the construction process, welding operations above the fill are strictly prohibited. If necessary, fire prevention measures must be taken.

-

When installation, maintenance, or other work needs to be carried out on the fill, it must be done on a flat plate. Direct stepping on the fill is strictly prohibited.

II. Benefits of Replacing After Cross Flow Film Fills For Cooling Towers Peplacement

-

Cross Flow Film Fills For Cooling Towers Improved Cooling Efficiency

-

New fill can increase the contact area between water and air, thereby improving cooling efficiency and ensuring that the cooling tower achieves its designed cooling effect.

-

After replacing the fill, the cooling efficiency of the cooling tower can be significantly improved. For example, Luopu Tianshan Cement Company improved its cooling efficiency by 15% after replacing the fill.

-

Cross Flow Film Fills For Cooling Towers Reduced Energy Consumption and Operating Costs

-

Cross Flow Film Fills For Cooling Towers Extended Service Life of the Cooling Tower

-

Old fill may affect the performance of the cooling tower due to aging, damage, or blockage. Timely replacement of the fill can reduce wear on other components of the cooling tower and extend its service life.

-

Cross Flow Film Fills For Cooling Towers Reduced Maintenance and Repair Frequency and Costs

-

After replacing the fill, the operation of the cooling tower becomes more stable, and the failure rate is significantly reduced, thereby reducing the frequency and costs of maintenance and repair.

-

Cross Flow Film Fills For Cooling Towers Reduced Carbon Emissions

In summary, regularly replacing the fill in a cooling tower is an important measure to maintain its performance. It not only improves cooling efficiency and reduces energy consumption but also extends the service life of the equipment and reduces maintenance costs. It has positive significance for both the economic benefits of enterprises and environmental protection.

Cross Flow Film Fills For Cooling Towers Size Measurement

Please measure the following data for the quality and reliability requirements of your maintenance cooling tower or maintenance project to adapt to the design of cooling tower filling or components.

Cross Flow Film Fills For Cooling Towers Application

The application range of film fills for cooling towers is: Industrial water cooling,Air compressor, Aluminum profile processing, Steam turbine, Power generation, Tannery, Electric furnace, Freezing Series, Air conditioning cooling system

Cross Flow Film Fills For Cooling Towers Shipment

Packing:

In bundle,wooden pallet or as your request.

Delivery time:

With in 10 days.

Our Services of Cross Flow Film Fills For Cooling Towers

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.