Cooling Tower Belt Reducer Overview

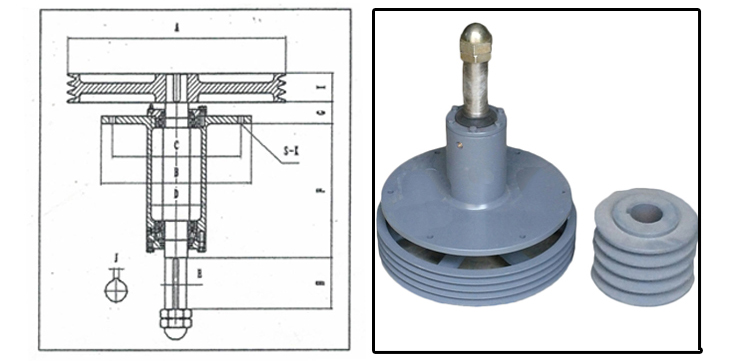

The cooling tower belt reducer is a reliable and cost-effective transmission system designed to reduce motor speed to the low RPM required for efficient fan operation. Comprising a motor pulley, fan pulley, and high-quality V-belts, it offers smooth operation, low noise, and easy maintenance. Available in upright and upside-down mounting configurations, it meets diverse cooling tower requirements.

Cooling Tower Belt Reducer Specifications

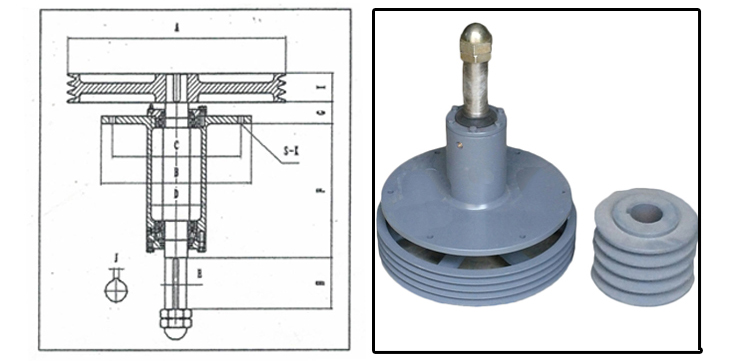

Our belt reducers are available in multiple models to suit various cooling tower designs. The table below details key specifications:

| Code | Description | 1#A | 2#A | 3#C | 4#C | 5#C | 6#C |

| A | Pulley Diameter | 356 | 508 | 508 | 600 | 660 | 660 |

| B | Flange Diameter | 350 | 350 | 350 | 450 | 520 | 520 |

| C | Install and Hole Diameter | 300 | 300 | 300 | 400 | 470 | 470 |

| D | Diameter | 120 | 138 | 138 | 138 | 170 | 170 |

| E | Fan Installed Shaft Diameter | 34 | 38 | 50 | 50 | 60 | 60 |

| F | Flange to Fan | 220 | 240 | 300 | 300 | 300 | 300 |

| G | Flange and Pulley Distance | 50 | 55 | 50 | 62 | 62 | 62 |

| H | Length of Axle Diameter | 80 | 105 | 115 | 138 | 145 | 145 |

| I | Thickness of Pulley | 50 | 45 | 65 | 85 | 105 | 125 |

| J | Flat Key Specifications | 8 | 10 | 12 | 12 | 12 | 12 |

| S-K | Number of Mounting Holes | 4-Φ14 | 4-Φ14 | 4-Φ14 | 4-Φ14 | 4-Φ14 | 4-Φ14 |

| L | Belt Groove Type/Number | A3 | B2 | B3 | B4 | B5 | B6 |

| Bearing Selection | Bearing Type | 208 | 209 | 211 | 211 | 214 | 214 |

| Bearing Type | 208 | 209 | 211 | 211 | 214 | 214 |

| Bearing Type | 7208 | 7209 | 7211 | 7211 | 7214 | 7214 |

When to Use Cooling Tower Belt Reducers

Belt reducers are ideal for specific cooling tower applications where their unique advantages enhance performance and efficiency. Key scenarios include:

Fan Speed Reduction

- Reduces high motor speeds to fan speeds of 200–800 RPM for efficient cooling.

Noise Control

- Low-noise operation suits civil cooling towers or HVAC systems in noise-sensitive areas.

Load Impact Buffering

- Buffers overload impacts to protect motor and fan bearings.

Ease of Installation and Maintenance

- Modular design allows quick installation and maintenance with adjustable tension.

Overload Protection

- Belt slippage prevents damage during sudden load changes.

Cost-Effectiveness

- Lower cost and longer service life compared to gear reducers.

Flexible Transmission Ratio

- Adjustable pulley ratios match motor and fan speeds for various tower specifications.

Key Characteristics of Cooling Tower Belt Reducers

Transmission Performance

- Smooth Operation: Elastic belts absorb load impacts, reducing vibration and noise.

- Wide Transmission Ratios: Adjustable pulley diameters offer ratios from a few to one to tens to one.

- Overload Protection: Belt slippage prevents damage to system components.

- High Efficiency: Achieves 70%–90% transmission efficiency with minimal energy loss.

Structure and Maintenance

- Compact Structure: Integrates pulley and reducer for space-efficient design.

- Easy Installation: Simple setup with adjustable tensioning devices.

- Simple Maintenance: Involves checking belt wear, tension, and reducer lubrication.

Cost

- Low Cost: Cost-effective manufacturing and materials compared to gear reducers.

Applications of Cooling Tower Belt Reducers

Belt reducers are used in various industries, including:

- Metallurgy and Mining: Supports heavy-load, long-hour equipment.

- Industrial Transportation: Powers continuous-operation conveyors.

- Refrigeration and Fans: Provides speed reduction and cooling in towers and fans.

- Chemical Machinery: Ensures stable transmission in high-temperature environments.

Packaging and Shipping

Packaging

Packaged in wooden crates, cartons, or customized per request.

Delivery Time

Shipped within 10 days.

Our Services for Cooling Tower Belt Reducers

Pre-Sale Services

We provide product images, videos, quotations, and engineering drawings tailored to your needs. Factory visits are welcome.

Sale Services

- Production schedule updates with photos.

- 24/7 support via phone, email, or online services.

- On-site installation guidance and training available.

After-Sale Services

12-month warranty with ongoing support to ensure optimal performance.

About PT

With over 20 years of experience, PT is a trusted global supplier of cooling tower components. Our expertise ensures high-quality, reliable solutions for industries worldwide. Request a Quote to explore how we can meet your cooling needs.

Frequently Asked Questions (FAQ)

What is the purpose of a cooling tower belt reducer?

It reduces motor speed to drive cooling tower fans efficiently at 200–800 RPM.

Why choose belt reducers over gear reducers?

Belt reducers are cost-effective, quieter, and provide overload protection.

What are the mounting options for belt reducers?

Available in upright and upside-down configurations.

How do belt reducers improve cooling tower performance?

They ensure smooth operation, low noise, and efficient speed reduction.

What maintenance is required for belt reducers?

Check belt wear, tension, and reducer lubrication regularly.

What industries use cooling tower belt reducers?

Metallurgy, mining, industrial transportation, and chemical machinery.

What is the delivery time for belt reducers?

Orders are delivered within 10 days.

Why Choose PT for Cooling Tower Belt Reducers?

- Premium Quality: Made with imported raw materials for durability.

- Competitive Pricing: Flexible pricing tailored to market demands.

- Expertise: Over 20 years of experience in cooling tower solutions.

- Superior Service: Comprehensive support with a 12-month warranty.