Cooling Tower Gear Reducer Overview

The cooling tower gear reducer is a critical component that drives fan operation by converting high-speed motor rotation into low-speed, high-torque output. This ensures efficient and reliable performance for cooling tower fans in various industrial applications.

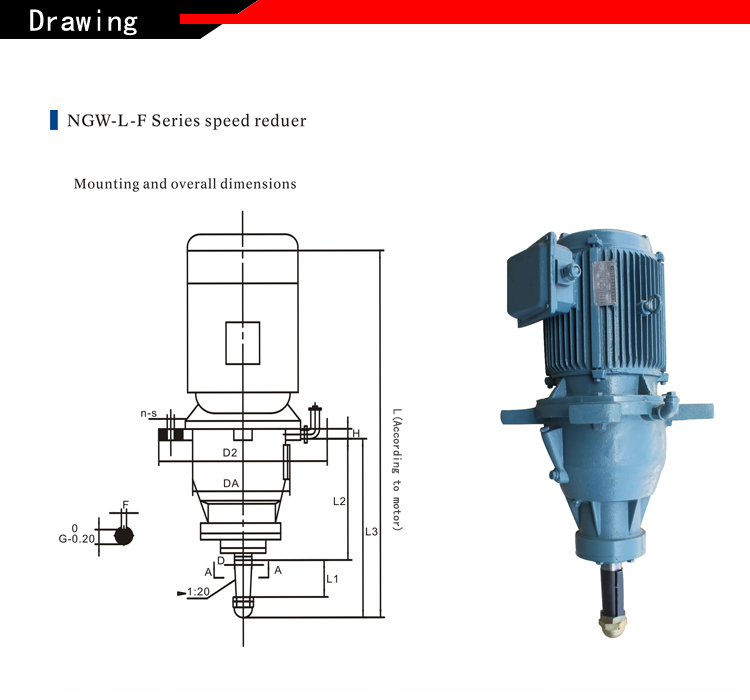

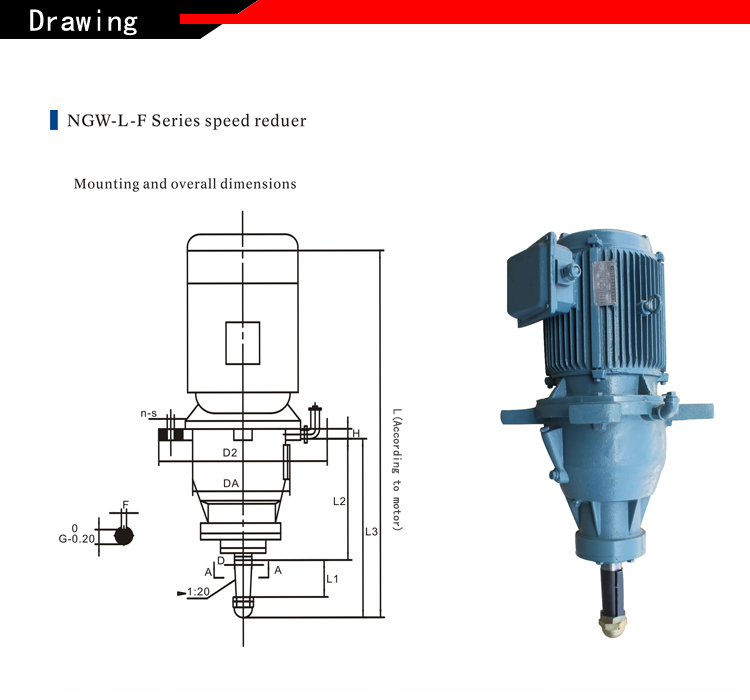

Cooling Tower Gear Reducer Specifications

Our gear reducers are designed for precision and durability, available in multiple frame sizes and models to suit your cooling tower requirements.

| Frame Size | Model | L | L2 | L3 | D2 | DA | D1 | N-S | H | D | L1 | G | F |

| 3 | NGW-L-F31 | By map | 374 | 553 | 510 | 314 | 450 | 4-Φ22 | 35 | 54KG | 115 | 19.6 | 16 |

| 6 | NGW-L-F61 | By map | 574 | 765 | 580 | 394 | 500 | 4-Φ22 | 35 | 70KG | 115 | 26.1 | 20 |

| 8 | NGW-L-F81 | By map | 574 | 765 | 750 | 500 | 660 | 4-Φ22 | 38 | 70KG | 115 | 26.1 | 20 |

When to Use a Cooling Tower Gear Reducer

Gear reducers are ideal for specific cooling tower applications where efficiency, reliability, and durability are critical. Key scenarios include:

High Torque and Heavy-Load Applications

Large-scale industrial cooling towers (e.g., power plants, steel mills) with heavy fan loads.

Provides high torque for stable fan operation under demanding conditions.

High-Efficiency Requirements

Space-Constrained Environments

Maintenance-Critical Systems

High-Speed Motor Applications

Harsh Environmental Conditions

Long-Term Durability

Applications of Cooling Tower Gear Reducers

Key Applications

Industrial Cooling Towers: Used in power plants, chemical plants, and steel mills for high-torque fan operation.

Central Air-Conditioning Systems: Ensures reliable cooling in large commercial buildings.

Harsh Environments: Sealed designs for high-temperature, high-humidity, or corrosive conditions.

Advantages

High Torque Output: Drives large fans efficiently at low speeds.

High Efficiency: Reduces energy loss for lower operating costs.

Compact Design: Fits space-constrained installations.

Reliability: Precision-machined gears ensure long-term performance.

Adaptability: Adjustable gear ratios for various motor and fan needs.

Considerations for Use

Lubrication: Regular oil changes maintain gear and bearing performance.

Installation Precision: Ensure coaxial alignment to prevent vibration.

Environmental Protection: Use sealed, corrosion-resistant models in harsh conditions.

Overload Protection: Equip with relays or torque limiters to prevent damage.

Selection Guidelines

Select based on fan speed, torque, and power requirements.

Choose protection levels suited to the installation environment.

Prioritize low-maintenance models for cost efficiency.

Packaging and Shipping

Packaging

Packaged in wooden crates, cartons, or customized per request.

Delivery Time

Shipped within 10 days.

Our Services for Cooling Tower Gear Reducers

Pre-Sale Services

We provide product images, videos, quotations, and engineering drawings tailored to your needs. Factory visits are welcome.

Sale Services

Production schedule updates with photos.

24/7 support via phone, email, or online services.

On-site installation guidance and training available.

After-Sale Services

12-month warranty with ongoing support to ensure optimal performance.

About PT

With over 20 years of experience, PT is a trusted global supplier of cooling tower components. Our expertise ensures high-quality, reliable solutions for industries worldwide. Request a Quote to explore how we can meet your cooling needs.

Frequently Asked Questions (FAQ)

What is the role of a cooling tower gear reducer?

It converts high-speed motor rotation into low-speed, high-torque output to drive cooling tower fans efficiently.

When should I use a gear reducer instead of a belt-driven system?

Use gear reducers for high-torque, heavy-load, space-constrained, or low-maintenance applications.

What maintenance is required for cooling tower gear reducers?

Regularly change lubricating oil and inspect gears and bearings for wear.

Are gear reducers suitable for harsh environments?

Yes, sealed and corrosion-resistant models are designed for high-humidity or corrosive conditions.

How do I select the right gear reducer for my cooling tower?

Consider fan speed, torque, environmental conditions, and maintenance needs.

What industries use cooling tower gear reducers?

Power plants, chemical plants, steel mills, and large-scale HVAC systems.

What is the delivery time for gear reducers?

Orders are delivered within 10 days.

How do I ensure proper installation of a gear reducer?

Ensure coaxial alignment of motor, reducer, and fan to avoid vibration and noise.

Why Choose PT for Cooling Tower Gear Reducers?

Premium Quality: Made with imported raw materials for durability.

Competitive Pricing: Flexible pricing tailored to market demands.

Expertise: Over 20 years of experience in cooling tower solutions.

Superior Service: Comprehensive support with a 12-month warranty.