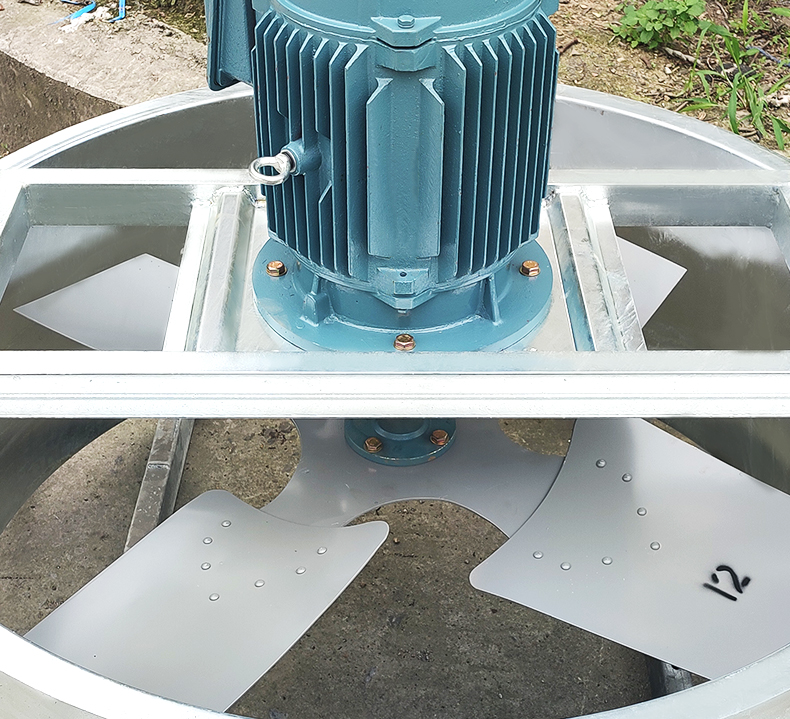

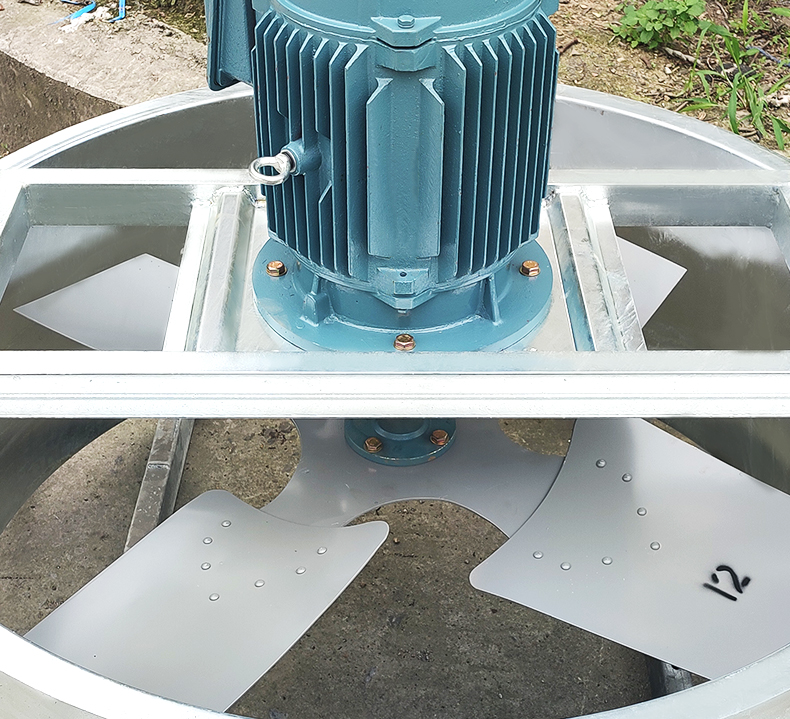

Fixed type fan blades refer to blades installed in a cooling tower, with fixed angles and positions at the factory, and do not have dynamic adjustment function. This design aims to optimize the air flow during the operation of the cooling tower, ensuring efficient and stable operation of the equipment under specific working conditions.

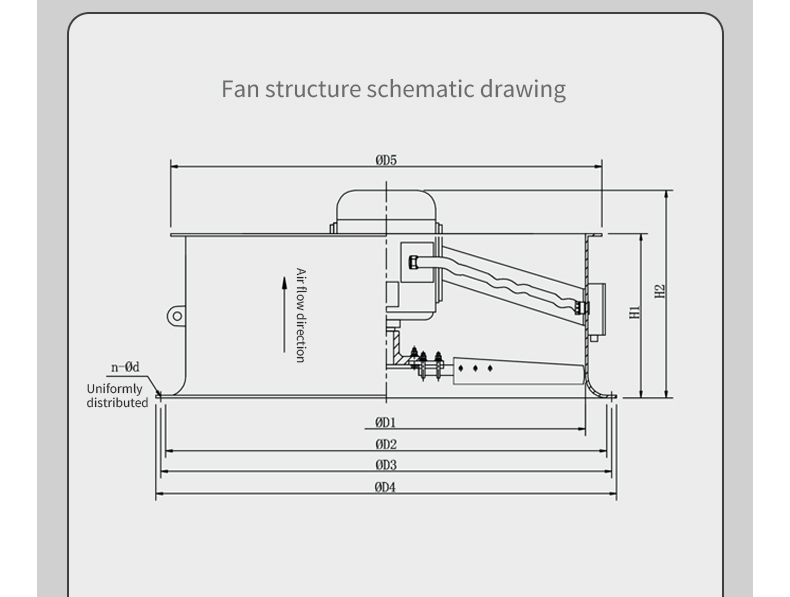

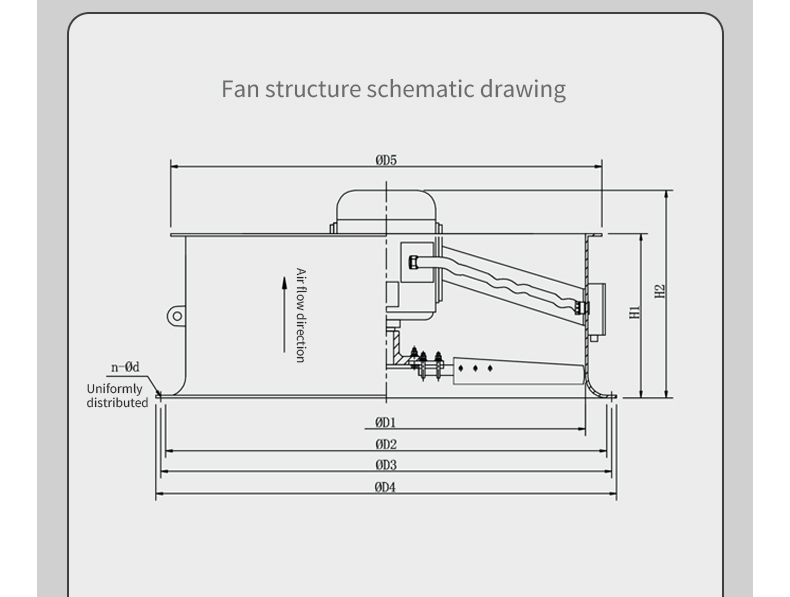

Fixed Type Fan For Coolling Tower Size Measurement

PT supplys cooling tower replacement service for brand cooling towers. Inform us below required information so that we could offer correctly: 1. Fan Diameter, 2. Nos of Fan Blades , 3. Blade Width , 4. Hub diameter

To match your existing driving shaft, shaft diameter, key width and hub height are also required when placing orders.

| Type | Fixed type |

| Blade number | 4 pieces |

| Feature | Non-detachable blade |

| Shaft | 42mm(can be customized) |

| Material | Aluminum plate |

| Size | 500-1800mm |

Fixed Type Fan For Cooling Tower Features

Fans are indispensable key components in cooling towers, primarily functioning to enhance the heat exchange efficiency between air and hot water through forced ventilation, thereby ensuring the efficient operation of cooling towers. The main function of fans is to drive air through the fill layer of the cooling tower. In counterflow cooling towers, fans draw air upward from the bottom of the tower, causing it to contact the hot water flowing downward in a counterflow manner; in crossflow cooling towers, fans draw air horizontally through the fill layer from the side. This forced ventilation significantly increases the contact time and area between air and hot water, thereby improving cooling efficiency.By increasing air flow, fans can more effectively remove heat from the hot water and release it into the atmosphere. Efficient air circulation ensures that the hot water forms a uniform film on the fill surface, further optimizing the heat exchange process. This not only enhances the cooling capacity of the cooling tower but also reduces the energy consumption of the system.The design and installation of fans need to ensure uniform air distribution across the fill layer. Uniform air distribution can prevent local overheating or insufficient cooling, ensuring consistent performance throughout the cooling tower. This is crucial for maintaining the efficient operation of the cooling tower.The rational design and operation of fans can reduce the phenomenon of water droplets being carried out of the cooling tower by the airflow, that is, reducing drift loss. Drift not only leads to water waste but can also impact the surrounding environment. By controlling the fan speed and airflow direction, drift can be effectively reduced.The stable operation of fans helps maintain the optimal operating conditions of the cooling tower. By adjusting the fan speed, different cooling demands can be met, ensuring efficient cooling performance under various operating conditions. This is of great significance for extending the service life of the cooling tower and reducing maintenance costs.

In summary, fans play a vital role in cooling towers. They not only improve cooling efficiency but also ensure the stable operation and high-performance of cooling towers by optimizing air distribution and reducing drift loss.

Fixed Type Fan For Cooling Tower Material Properties

Fixed Type Fan For Coolong Tower Lightweight:

Aluminum has a relatively low density, making the blades significantly lighter. This not only facilitates the installation and transportation of the blades but also reduces the overall load on the cooling tower structure, decreasing the requirements for structural strength.

Fixed Type Fan For Cooling Tower Corrosion Resistance:

Aluminum exhibits excellent corrosion resistance, capable of withstanding the effects of various chemical substances. During the operation of cooling towers, the blades are often exposed to moist air containing salts and other chemical components. The aluminum blades can maintain stable performance in such a humid and potentially corrosive environment, extending their service life.

Fixed Type Fan For Cooling Tower Strength and Toughness:

Despite their lightweight, aluminum blades possess high strength and toughness. They can withstand the wind pressure and mechanical stress during operation without deforming or breaking, ensuring the stable operation of the cooling tower.

Structural and Design Features

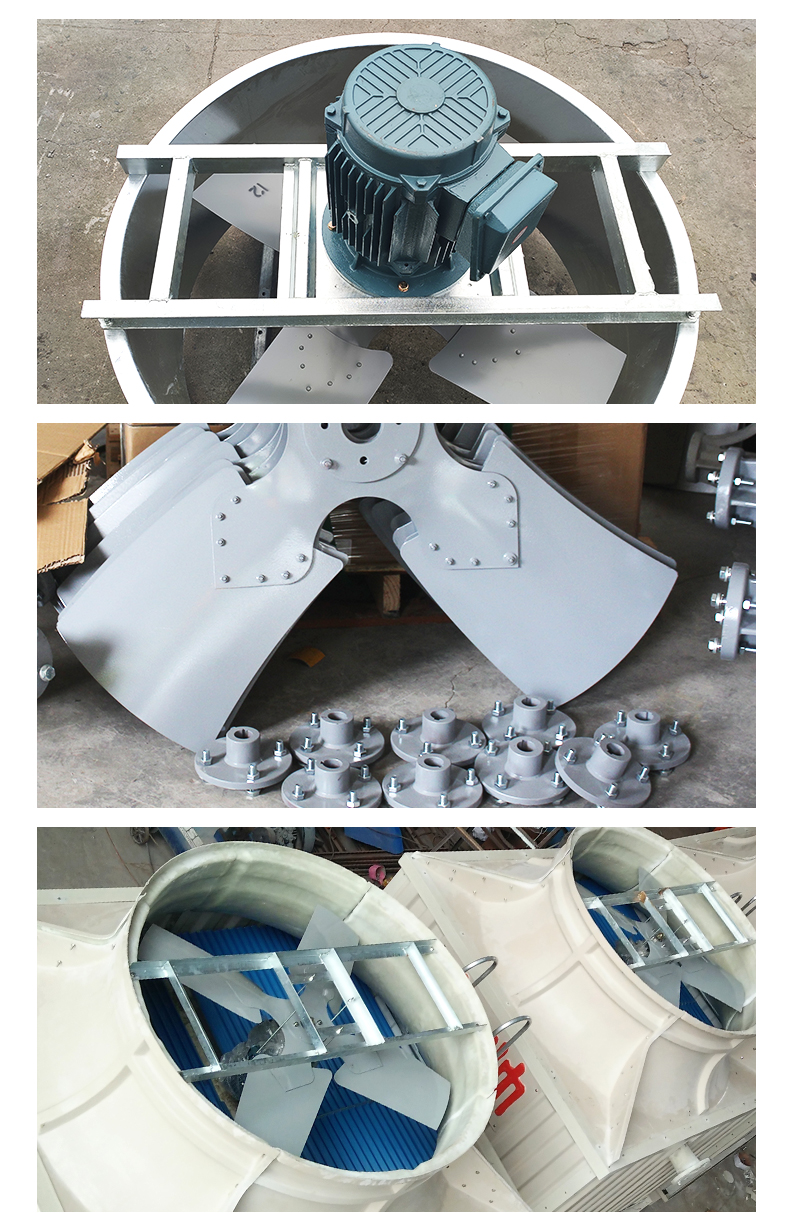

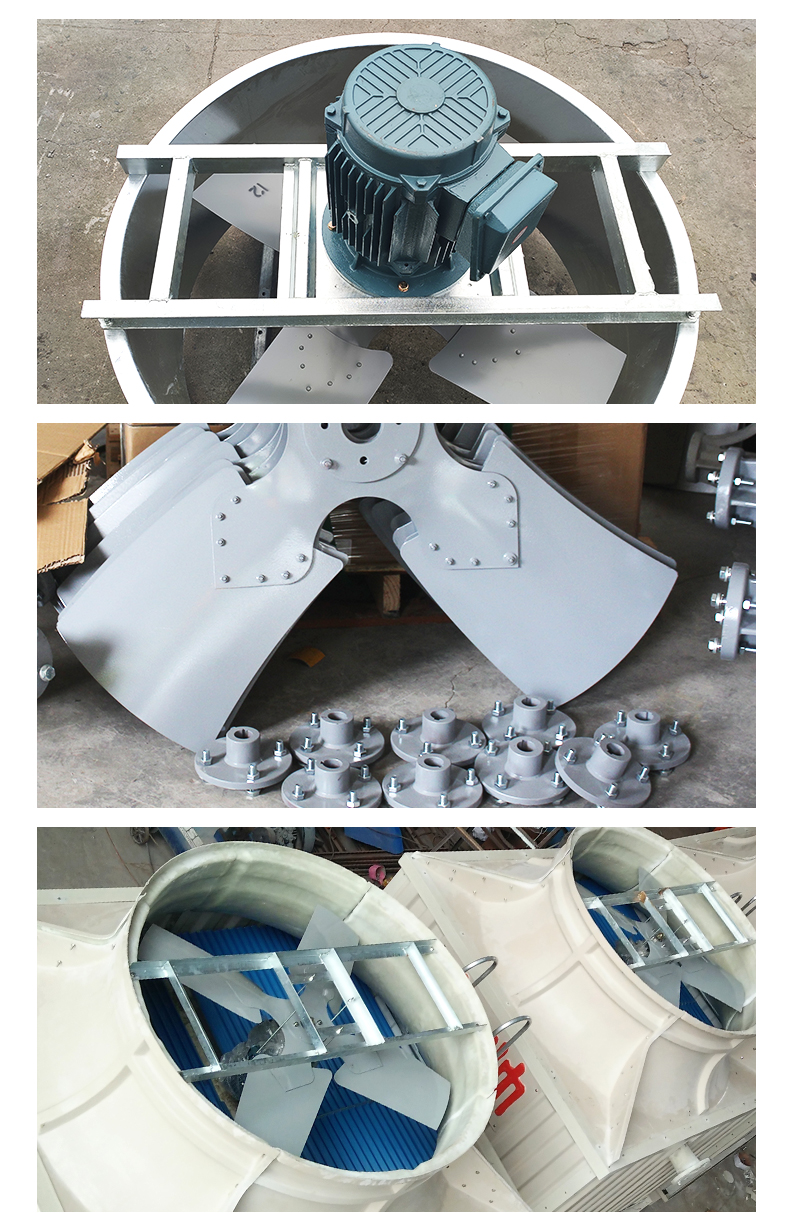

Fixed Type Fan For Cooling Tower Unique Shape Design:

Fixed aluminum plate blades for cooling towers typically feature a twisted shape. This design enhances air flow efficiency, allowing air to pass through the blades more smoothly and improving the cooling performance of the tower.

Fixed Type Fan For Cooling Tower Fixed Installation:

Unlike adjustable-angle blades, fixed aluminum blades are simpler to install. Once installed, their angle and position remain constant, eliminating the need for frequent adjustments. This reduces maintenance workload and costs.

Fixed Type Fan For Cooling Tower Excellent Aerodynamic Performance:

The shape and structure of the blades are carefully designed to achieve optimal aerodynamic performance. During operation, the blades can effectively draw air into the cooling tower and accelerate its discharge, promoting heat dissipation. Additionally, the well-designed aerodynamics minimize the resistance encountered by the blades during operation, enhancing the efficiency of the fan.

Fixed Type Fan For Cooling Tower Performance Features

Fixed Type Fan For Cooling Tower High Cooling Efficiency:

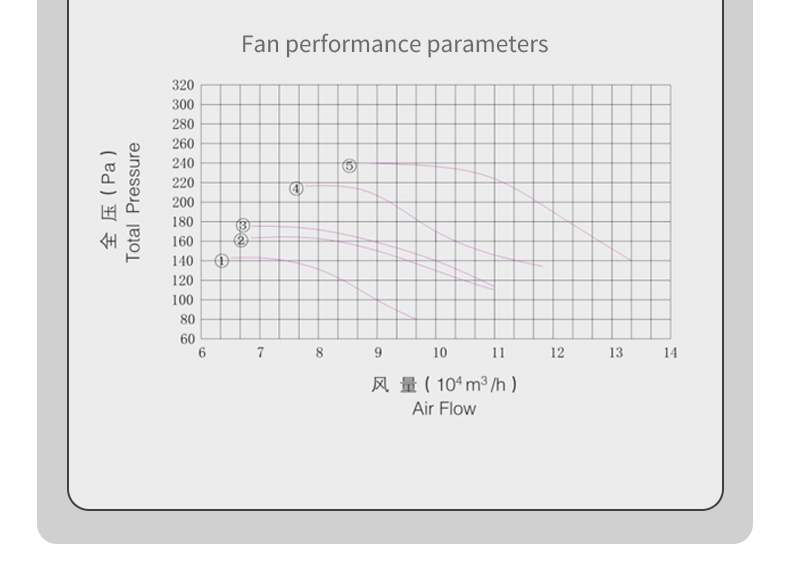

The excellent aerodynamic performance of aluminum blades provides strong ventilation capabilities for the cooling tower. Within a unit of time, more air can be introduced into the cooling tower, accelerating the heat exchange between hot water and air, and achieving the desired cooling effect on the cooling water.

Low Noise Operation: Thanks to the well-designed aerodynamics, the blades produce relatively low noise during operation. This is particularly important in environments sensitive to noise, as it reduces the impact of cooling tower operation on the surrounding area. It also meets environmental requirements and provides a quieter working environment for personnel.

Fixed Type Fan For Cooling Tower Stable Operation:

Aluminum blades are highly stable and durable. They maintain consistent performance over long-term operation, without deformation, damage, or loosening that could lead to reduced cooling efficiency or equipment failure. This ensures the continuous and stable operation of the cooling tower, minimizing downtime and maintenance costs.

Maintenance and Service Life

Fixed Type Fan For Cooling Tower Easy Maintenance:

Fixed aluminum blades require minimal maintenance. Since their angle does not need frequent adjustment, regular cleaning and inspection are sufficient for routine care. Additionally, the corrosion resistance and durability of aluminum reduce the need for repairs due to material aging or corrosion.

Long Service Life: Under normal use and maintenance conditions, aluminum blades have a long service life. Their corrosion resistance and high strength allow them to operate effectively in harsh environments for extended periods without damage, reducing the frequency of blade replacements and lowering overall operating costs.

Environmental and Energy Efficiency

Fixed Type Fan For Cooling Tower Significant Energy Savings:

The high aerodynamic efficiency and low resistance design of aluminum blades enable the fan to achieve high airflow with lower energy consumption. This not only reduces the operating costs of the cooling tower but also aligns with energy-saving and environmental protection requirements, helping to minimize energy consumption and carbon emissions.

Fixed Type Fan For Cooling Tower Recyclability:

Aluminum is a recyclable material. At the end of their service life, aluminum blades can be recycled and reused. This not only reduces waste emissions but also conserves resources and lowers production costs.

In summary, fixed aluminum plate blades for cooling towers possess numerous excellent characteristics, including lightweight, corrosion resistance, high strength, high cooling efficiency, low noise, stable operation, easy maintenance, long service life, significant energy savings, and recyclability. These features make aluminum blades an ideal choice for cooling towers, meeting the demands of industrial and commercial cooling towers in terms of performance, environmental friendliness, and cost-effectiveness.

Fixed Type Fan For Coolling Tower Application

1. Industrial cooling tower

Widely used in large cooling towers in industries such as chemical, steel, and power.

2. Commercial buildings

Used for commercial refrigeration systems (such as air conditioning cooling towers).

3. Places with harsh environmental conditions

Suitable for high temperature, high humidity, or corrosive gas environments.

Fixed Type Fan For Coolling Tower Packing

Packing:

In bundle,wooden pallet or as your request.

Delivery time:

With in 10 days.

Selling units:

Single item.

Our Services Of Fixed Type Fan For Cooling Tower

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.