Compression molding process, is the current advanced manufacturing processof FRP fan stacks, it uses impregnated film material as raw material, the product pressedby hydraulic press for power, first of all, a certain amount of molding material placedin the metal mold, and then in 150-170'c temperature and 1500-4000 tons of pressuremolding, the product size is accurate, the surface is smooth, and the product size isaccurate. lt can be formed once, the production efficiency is high, and the productquality is stable, suitable for mass production of various FRP products.

Water Cooling Tower FRP Fan Stacks Specification

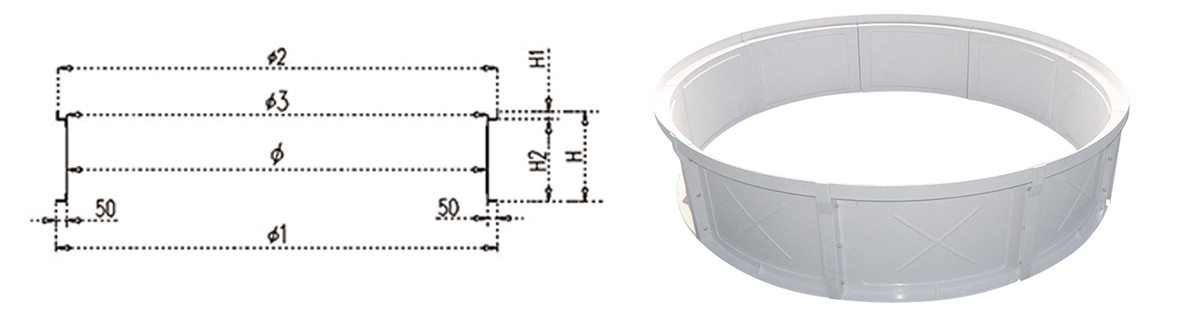

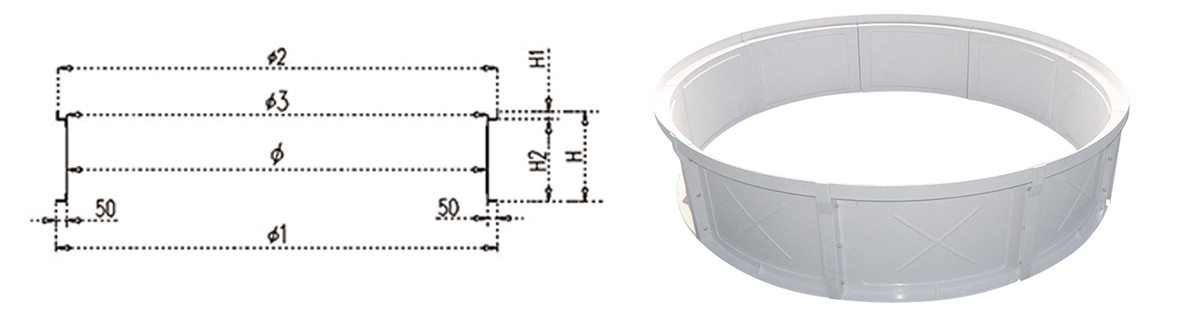

ABLZ-18-50 # Mold pressing (bearing straight air duct) parameters

| No. | Model | H | H1 | H2 | φ | φ1 | φ2 | φ3 | PCS of fan

stack | Screws

type | Screws qty |

| 1 | ABLZ-18 | 520 | 50 | 470 | 1840 | 1950 | 1955 | 1850 | 9 | M8*30 | 27Set |

| 2 | ABLZ-20 | 520 | 50 | 470 | 2040 | 2140 | 2170 | 2050 | 10 | M8*30 | 30Set |

| 3 | ABLZ-21 | 520 | 50 | 470 | 2140 | 2250 | 2257 | 2150 | 10 | M8*30 | 40Set |

| 4 | ABLZ-22 | 520 | 50 | 470 | 2240 | 2350 | 2370 | 2245 | 11 | M8*30 | 33Set |

| 5 | ABLZ-24 | 520 | 60 | 460 | 2440 | 2550 | 2570 | 2450 | 12 | M8*30 | 36Set |

| 6 | ABLZ-26 | 520 | 60 | 460 | 2650 | 2760 | 2780 | 2660 | 13 | M8*30 | 52Set |

| 7 | ABLZ-28 | 520 | 60 | 460 | 2840 | 2950 | 2960 | 2850 | 14 | M8*30 | 56Set |

| 8 | ABLZ-30 | 620 | 70 | 550 | 3040 | 3150 | 3170 | 3050 | 15 | M8*30 | 75Set |

| 9 | ABLZ-32 | 620 | 70 | 550 | 3220 | 3330 | 3350 | 3230 | 16 | M8*30 | 80Set |

| 10 | ABLZ-34 | 620 | 70 | 550 | 3440 | 3550 | 3560 | 3450 | 16 | M8*30 | 48Set |

| 11 | ABLZ-36 | 620 | 70 | 550 | 3660 | 3770 | 3800 | 3675 | 17 | M8*30 | 51Set |

| 12 | ABLZ-37 | 620 | 70 | 550 | 3740 | 3850 | 3870 | 3750 | 18 | M8*30 | 90Set |

| 13 | ABLZ-38 | 670 | 70 | 600 | 3825 | 3940 | 3950 | 3835 | 18 | M8*30 | 54Set |

| 14 | ABLZ-40 | 670 | 70 | 600 | 4040 | 4155 | 4190 | 4050 | 19 | M8*30 | 57Set |

| 15 | ABLZ-42 | 850 | 70 | 780 | 4260 | 4370 | 4410 | 4270 | 20 | M8*30 | 120Set |

| 16 | ABLZ-47 | 850 | 70 | 780 | 4740 | 4870 | 4890 | 4750 | 22 | M8*30 | 132Set |

| 17 | ABLZ-50 | 850 | 70 | 780 | 5040 | 5170 | 5190 | 5050 | 24 | M8*30 | 144Set |

Note: 1.Number 1-7,fan stack flat surface thickness:3mm,fan stacks thickness:6mm

2.Number 8-17,fan stack flat surface thickness:3mm,fan stacks thickness:7mm

Selection of Water Cooling Tower FRP Fan Stacks

Cooling Tower Fan Stacks are an essential component of cooling towers, and their performance and quality directly affect the operational efficiency and service life of the cooling tower. Selecting the appropriate fiberglass fan stacks requires a comprehensive consideration of various factors, including the type of cooling tower, operating environment, material characteristics, design optimization, and the reliability of the supplier. Below is a detailed explanation of how to select cooling tower fiberglass fan stacks:

I. Performance Characteristics of Water Cooling Tower FRP Fan Stacks

Water Cooling Tower FRP Fan Stacks High Corrosion Resistance

Fiberglass materials possess excellent corrosion resistance, capable of withstanding the erosion of common acids, alkalis, and salts encountered during the operation of cooling towers, thereby extending the service life of the fan stacks.

Water Cooling Tower FRP Fan Stacks High Strength

Water Cooling Tower FRP Fan Stacks are manufactured using high-strength epoxy fiberglass molding processes, which provide high mechanical strength and the ability to withstand significant wind pressure and airflow impact.

Water Cooling Tower FRP Fan Stacks Lightweight

The density of fiberglass materials is relatively low, making the fan stacks lightweight and easy to install and maintain.

Water Cooling Tower FRP Fan Stacks Good Aerodynamic Performance

Fiberglass Water Cooling Tower FRP Fan Stacks are typically designed with streamlined shapes to effectively reduce air resistance, increase airflow and pressure, and enhance the cooling efficiency of the cooling tower.

Water Cooling Tower FRP Fan Stacks UV Resistance and Aging Prevention

The surface of fiberglass cooling tower fan stacks is often treated with special coatings, such as UV-resistant layers, to extend their service life and color stability under strong sunlight.

II. Key Considerations for Selecting Water Cooling Tower FRP Fan Stacks

(i) Water Cooling Tower FRP Fan Stacks Selection Based on Cooling Tower Type and Specifications

Counterflow Cooling Towers Fan Stacks

The Cooling Tower Fan Stacks design for counterflow cooling towers typically requires higher strength and better aerodynamic performance to accommodate higher wind pressure and complex airflow organization.

Crossflow Cooling Towers Fan Stacks

The Cooling Tower Fan Stacks design for crossflow cooling towers is relatively simpler but must consider the horizontal airflow characteristics to ensure effective airflow guidance.

Size Of Cooling Tower FRP Fan Stacks

The diameter and height of the Cooling Tower Fan Stacks should be matched with the overall design of the cooling tower to ensure smooth airflow and prevent airflow short-circuiting.

(ii) Water Cooling Tower FRP Fan Stacks Selection Based on Operating Conditions of the Cooling Tower

Airflow and Pressure

The airflow and pressure of the FRP Cooling Tower Fan Stacks are critical factors affecting the cooling efficiency of the cooling tower. The fan stacks should be selected based on the design parameters and actual operating conditions of the cooling tower to provide sufficient airflow and pressure.

Air-to-Water Ratio

The air-to-water ratio is an important parameter for cooling tower operation, determining the heat exchange efficiency between cold air and hot water. When selecting FRP Cooling Tower Fan Stacks, their impact on the air-to-water ratio should be considered to ensure optimal operation of the cooling tower.

Water Cooling Tower FRP Fan Stacks Environmental Temperature and Humidity

If the cooling tower operates in a high-temperature and high-humidity environment, the FRP Cooling Tower Fan Stacks need to have better corrosion resistance and aging resistance.

(iii) Water Cooling Tower FRP Fan Stacks Selection Based on Material and Manufacturing Processes

Water Cooling Tower FRP Fan Stacks High-Strength Epoxy Fiberglass Molding

Water Cooling Tower FRP Fan Stacks manufactured using this process feature high strength and precision, ensuring the performance and quality of the fan stacks.

Water Cooling Tower FRP Fan Stacks Hollow Structure

Hollow-structured Water Cooling Tower FRP Fan Stacks offer the advantages of being lightweight and strong, but precautions should be taken to prevent internal water seepage and freezing that could damage the fan stacks.

Water Cooling Tower FRP Fan Stacks Surface Treatment

The surface of the Water Cooling Tower FRP Fan Stacks is often specially treated, such as with UV-resistant coatings, to extend their service life and color stability under strong sunlight.

(iv)Water Cooling Tower FRP Fan Stacks Selection Based on Design Optimization

Water Cooling Tower FRP Fan Stacks Hyperbolic Design

The hyperbolic Water Cooling Tower FRP Fan Stacks design can effectively reduce air resistance, improve airflow uniformity, and reduce stress on the fan stacks. The geometric parameters of the hyperbolic fan stacks (such as the throat diameter, the ratio of the distance from the throat to the top of the tower to the total height of the tower, etc.) need to be optimized based on specific operating conditions.

Extended Water Cooling Tower FRP Fan Stacks

In some applications, extended Water Cooling Tower FRP Fan Stacks can bring the outlet to a position higher than the existing motor outside the fan stacks, enhancing UV stability. This is suitable for situations where the exhaust gases need to be directed outside of enclosed spaces.

(v) Water Cooling Tower FRP Fan Stacks Selection Based on Installation and Maintenance Requirements

Water Cooling Tower FRP Fan Stacks Ease of Installation

Selecting Cooling Tower Fan Stacks that are easy to install can reduce installation time and costs. For example, some fan stacks are designed with special installation structures that allow for quick and secure attachment to the cooling tower.

Water Cooling Tower FRP Fan Stacks Ease of Maintenance

Although Water Cooling Tower FRP Fan Stacks require relatively simple maintenance, regular inspection and upkeep are still necessary. Choosing Cooling Tower Fan Stacks that are easy to maintain can reduce maintenance costs.

III. Installation and Maintenance of Water Cooling Tower FRP Fan Stacks

(i) Water Cooling Tower FRP Fan Stacks Installation Steps

Inspect the Water Cooling Tower FRP Fan Stacks

Before installation, carefully inspect the fan stack for any damage or deformation to ensure their integrity.

Adjust the Angle of Water Cooling Tower FRP Fan Stacks

Based on the design requirements of the cooling tower, adjust the installation angle of the fan stack to ensure optimal airflow direction and volume.

Secure the Water Cooling Tower FRP Fan Stacks

Firmly attach the fan stacks to the cooling tower to ensure they do not loosen during operation.

Water Cooling Tower FRP Fan Stacks Features

This product is a standardized product with high production efficiency,facilitating fast, large-scale production,and automated production.

The products produced by the molding process have high dimensional accuracy, no need to cut the edges,no deformation, and very convenient installation.

The interal and external surfaces of the product are smooth and contain anti UV agents, which have strong weather resistance and do not require secondary modification.

The product has a reasonable structural design, high vibration resistance, andeffectively avoids vibration.

The product is high-temperature pressed,therefore the product has high density,standardized molding, and no defects.

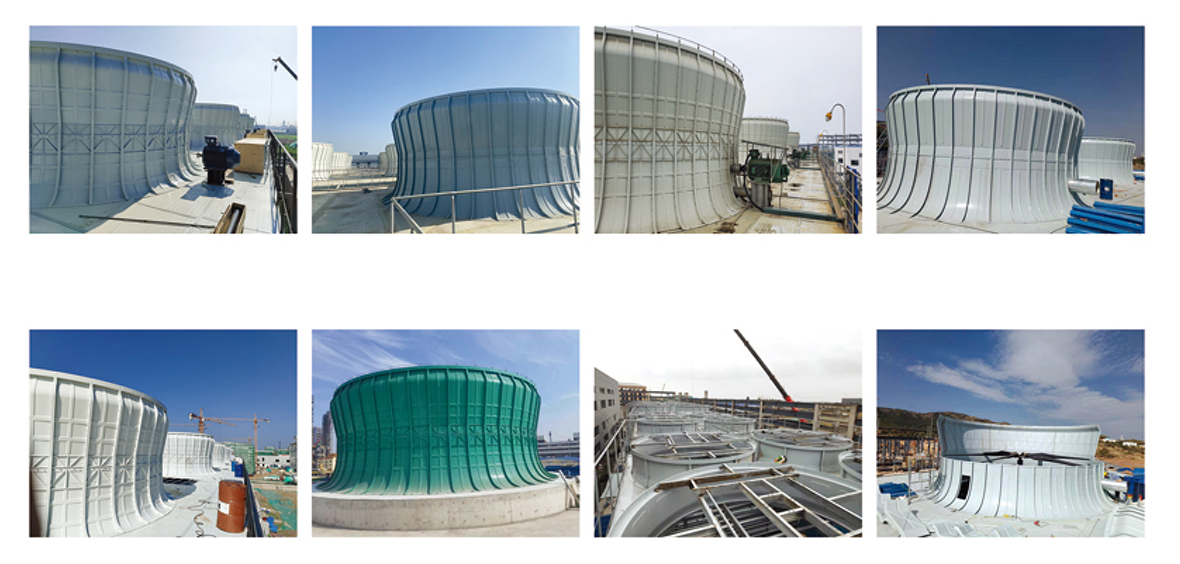

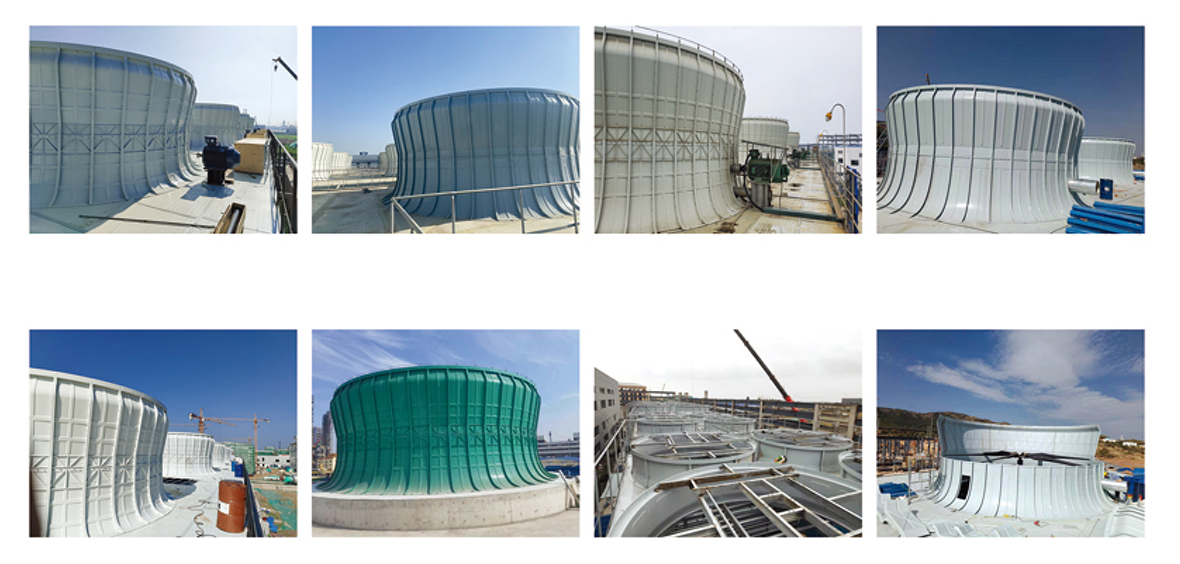

Water Cooling Tower FRP Fan Stacks Application

The application range is: Industrial water cooling,Air compressor, Aluminum profile processing, Steam turbine, Power generation, Tannery, Electric furnace, Freezing Series, Air conditioning cooling system

Water Cooling Tower FRP Fan Stacks Shipment

Packing:

Wooden,cartons,custom package.

Delivery time:

With in 10 days.

Our Services Of Water Cooling Tower FRP Fan Stacks

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.