Molded Cooling Tower FRP Fan Stack Overview

Molded FRP fan stacks are critical components of cooling towers, designed to optimize airflow and enhance cooling efficiency. Manufactured using a compression molding process with high-strength epoxy fiberglass, these fan stacks offer superior corrosion resistance, lightweight design, and precise dimensions for reliable performance in industrial and commercial cooling systems.

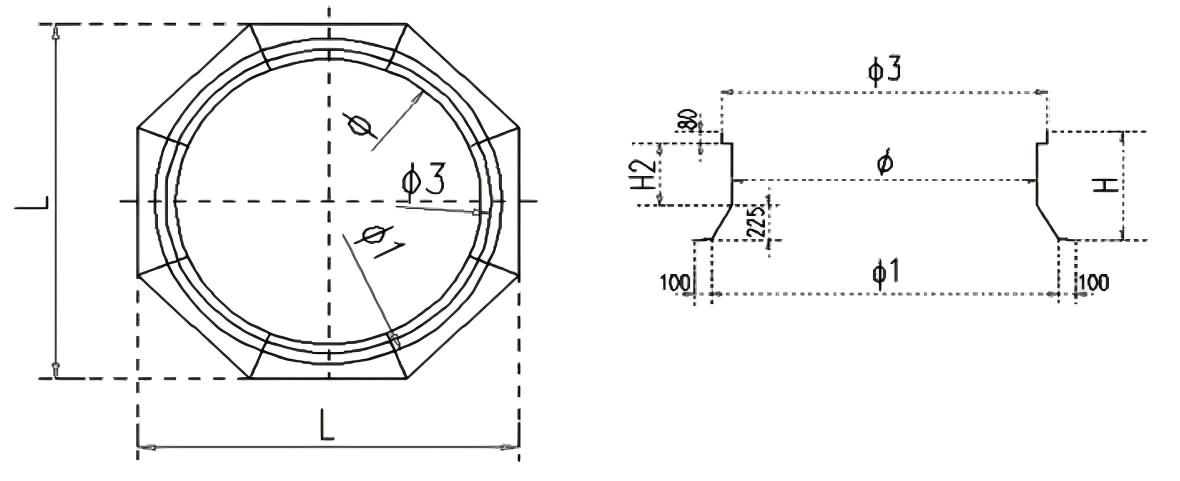

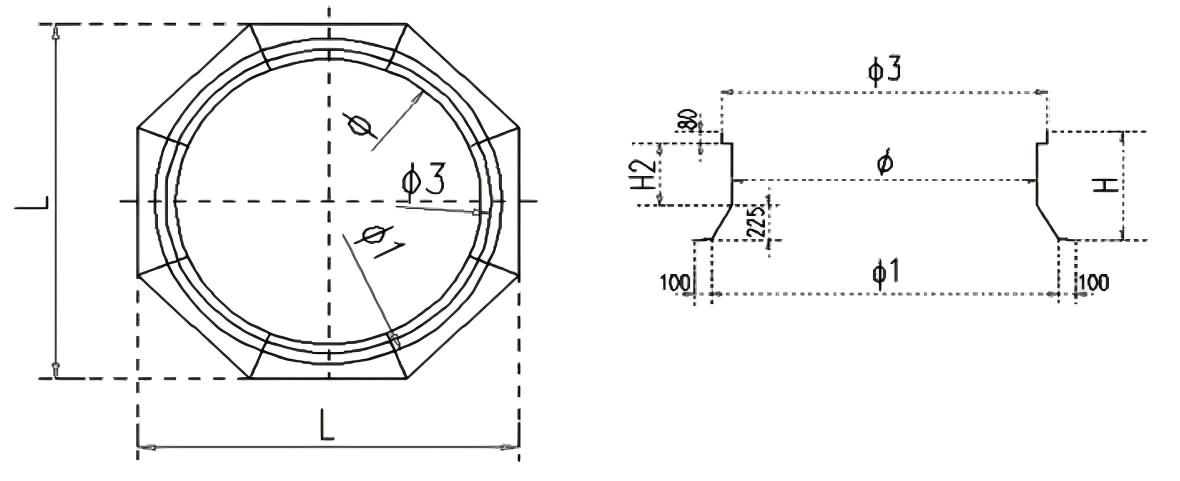

Molded Cooling Tower FRP Fan Stack Specifications

Our FRP fan stacks are available in multiple models with customizable dimensions to suit various cooling tower designs. The table below outlines key specifications:

| No. | Model | H (mm) | H2 (mm) | Φ (mm) | Φ1 (mm) | Φ3 (mm) | L (mm) | PCS of Fan Stack | Screws Type | Screws Qty |

| 1 | ABF-18 | 705 | 400 | 1863 | 2125 | 1990 | 2320 | 8 | M10*30 | 32 Set |

| 2 | ABF-21 | 705 | 400 | 2165 | 2440 | 2283 | 2640 | 8 | M10*30 | 32 Set |

| 3 | ABF-24 | 705 | 400 | 2465 | 2600 | 2585 | 2800 | 8 | M10*30 | 32 Set |

Note: All fan stack planes have a thickness of 4mm; fan stack thickness is 6mm.

Key Features of Molded Cooling Tower FRP Fan Stacks

High Production Efficiency: Standardized compression molding ensures fast, large-scale, automated production.

Precision Manufacturing: High dimensional accuracy with smooth edges, no deformation, and easy installation.

UV Resistance: Anti-UV coatings ensure durability and color stability in outdoor conditions.

Vibration Resistance: Robust design minimizes vibration for stable operation.

High Density: High-temperature pressing ensures defect-free, durable fan stacks.

Selection Criteria for Molded Cooling Tower FRP Fan Stacks

Performance Characteristics

Corrosion Resistance: Withstands acids, alkalis, and salts for extended service life.

High Strength: Epoxy fiberglass molding ensures durability under wind pressure.

Lightweight: Low density simplifies installation and maintenance.

Aerodynamic Performance: Streamlined shapes reduce air resistance and enhance cooling efficiency.

UV Resistance: UV-resistant coatings maintain performance in sunlight.

Cooling Tower Type and Specifications

Counterflow Cooling Towers: Require high-strength, aerodynamic fan stacks for complex airflow.

Crossflow Cooling Towers: Designed for effective horizontal airflow guidance.

Size Matching: Ensure diameter and height align with tower design to prevent airflow short-circuiting.

Operating Conditions

Airflow and Pressure: Select fan stacks to meet specific airflow and pressure requirements.

Air-to-Water Ratio: Optimize heat exchange efficiency based on tower parameters.

Environmental Conditions: Choose enhanced corrosion and UV resistance for high-temperature or humid environments.

Material and Manufacturing

Epoxy Fiberglass Molding: Ensures high strength and precision.

Hollow Structure: Lightweight yet strong, with precautions against water seepage.

Surface Treatment: UV-resistant coatings for longevity.

Design Optimization

Installation and Maintenance

Ease of Installation: Designed for quick, secure attachment.

Low Maintenance: Requires minimal upkeep with regular inspections.

Installation Steps

Inspect fan stacks for damage or deformation before installation.

Adjust installation angle for optimal airflow direction.

Securely attach fan stacks to prevent loosening during operation.

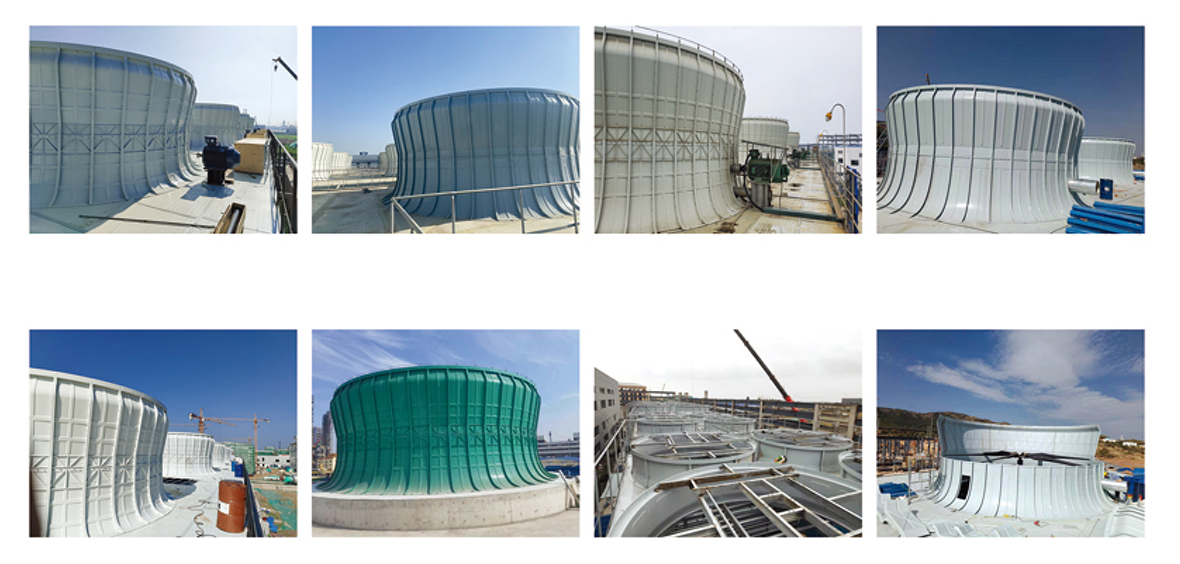

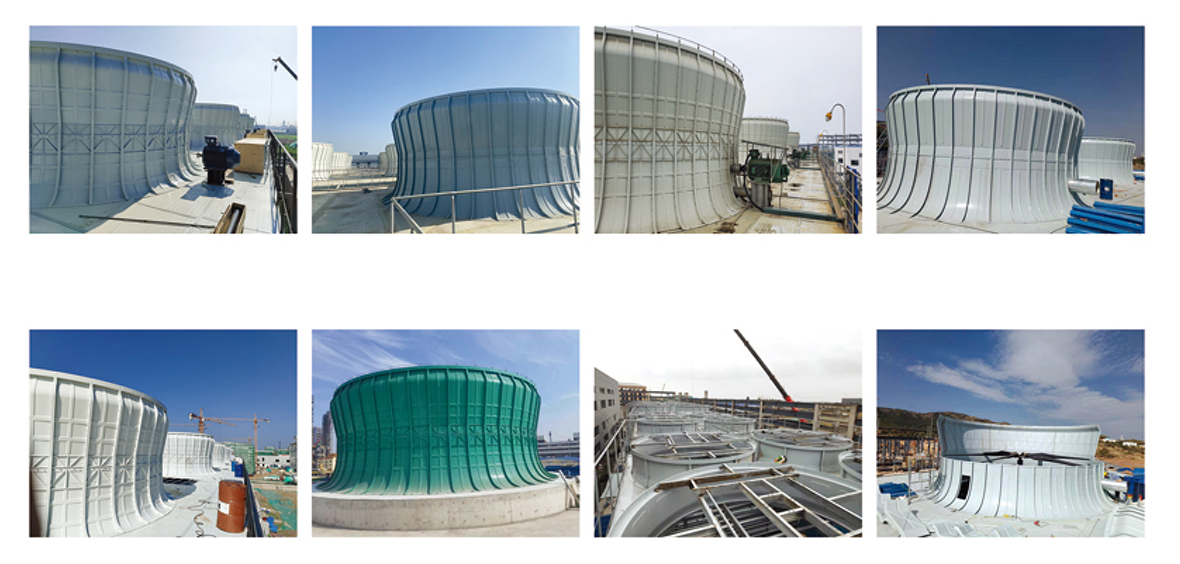

Applications of Molded Cooling Tower FRP Fan Stacks

FRP fan stacks are used in various industries, including:

Packaging and Shipping

Packaging

Packaged in wooden crates, cartons, or customized per request.

Delivery Time

Shipped within 10 days.

Our Services for Molded Cooling Tower FRP Fan Stacks

Pre-Sale Services

We provide product images, videos, quotations, and engineering drawings tailored to your needs. Factory visits are welcome.

Sale Services

Production schedule updates with photos.

24/7 support via phone, email, or online services.

On-site installation guidance and training available.

After-Sale Services

12-month warranty with ongoing support to ensure optimal performance.

About PT

With over 20 years of experience, PT is a trusted global supplier of cooling tower components. Our expertise ensures high-quality, reliable solutions for industries worldwide. Request a Quote to explore how we can meet your cooling needs.

Frequently Asked Questions (FAQ)

What is the purpose of FRP fan stacks in cooling towers?

They optimize airflow, enhance cooling efficiency, and protect fan components.

Why choose FRP fan stacks over metal ones?

FRP fan stacks are corrosion-resistant, lightweight, and require less maintenance.

Can FRP fan stacks be customized?

Yes, dimensions and designs can be tailored to specific cooling tower requirements.

Are FRP fan stacks suitable for harsh environments?

Yes, they offer excellent corrosion and UV resistance for high-temperature or humid conditions.

How do FRP fan stacks improve cooling efficiency?

Their hyperbolic design reduces air resistance and optimizes airflow uniformity.

What is the lifespan of FRP fan stacks?

With proper maintenance, they last over 10 years due to their durability.

What industries use FRP fan stacks?

Power generation, chemical processing, HVAC, and more.

What is the delivery time for FRP fan stacks?

Orders are delivered within 10 days.

Why Choose PT for Molded Cooling Tower FRP Fan Stacks?

Premium Quality: Made with imported raw materials for durability.

Competitive Pricing: Flexible pricing tailored to market demands.

Expertise: Over 20 years of experience in cooling tower solutions.

Superior Service: Comprehensive support with a 12-month warranty.