Cooling Tower Fill is one of the most essential heat exchange components in a cooling tower. Its main function is to increase the contact area between water and air, prolong their contact time, and thus improve the heat exchange efficiency of the cooling tower. High quality fillers can significantly improve cooling capacity, reduce energy consumption, and extend equipment lifespan.

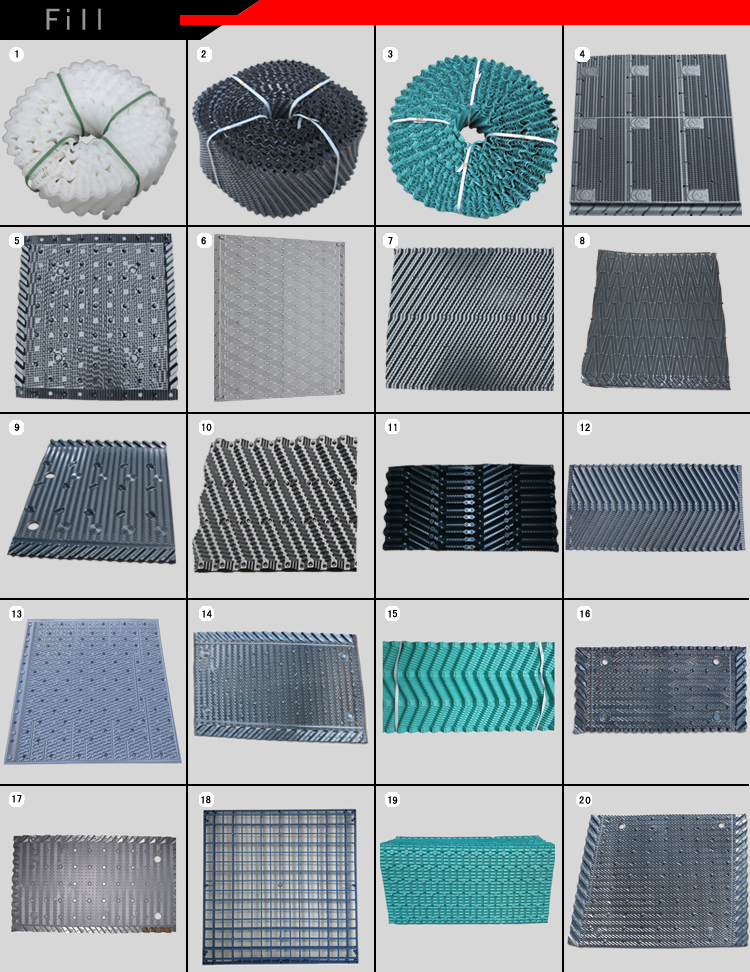

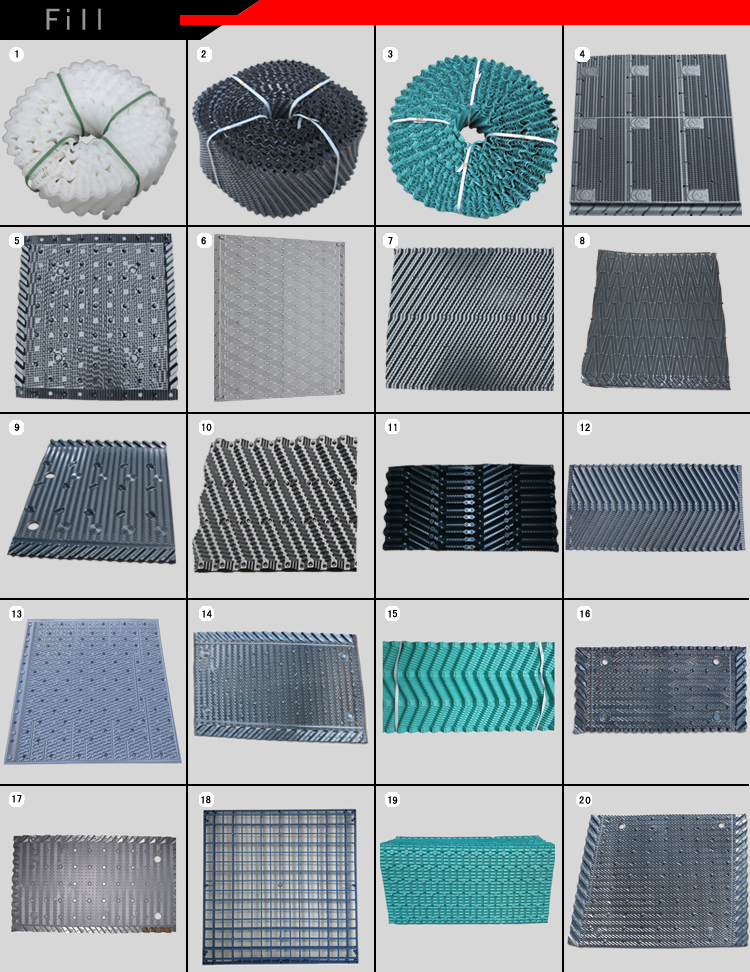

Picture Of Cooling Tower Fill

Cooling tower fill promotes heat and mass exchange between water and air by providing a large surface area. When hot water is sprayed down from the top of the fill, air usually enters from the bottom or side, flowing in reverse or cross flow. Water forms a thin film or disperses into small droplets on the surface of the filler, thereby increasing the contact area with air. Heat is transferred from water to the air, and some of the water evaporates, taking away latent heat and further lowering the water temperature. This process relies on the geometric design of the filler, including its shape, porosity, and material properties, to ensure efficient heat transfer and low air resistance.

Cooling tower fill material plays a critical role in improving the efficiency of heat exchange in cooling towers. Here are some key advantages of cooling tower fill materials:

1.Increased Heat Transfer Efficiency:

The primary function of fill material is to increase the surface area for heat exchange between water and air. By providing more surface area, it helps cool the water more effectively, improving the overall heat transfer efficiency.

2.Enhanced Air and Water Contact:

The fill creates pathways that allow for better interaction between air and water, ensuring the water is exposed to the cooling air for a longer period. This maximizes the heat dissipation process.

3.Optimized Water Distribution:

The design of cooling tower fill ensures uniform distribution of water over the entire surface area, preventing hot spots and improving cooling performance.

4.Reduced Water Consumption:

The efficient heat transfer facilitated by the fill material means less water is needed to achieve the desired cooling effect, leading to potential savings in water usage.

5.Improved Performance in High-Temperature Conditions:

Cooling tower fills help maintain cooling efficiency even under high thermal loads or extreme temperatures, ensuring reliable performance in varying operational conditions.

6.Durability and Corrosion Resistance:

Modern fill materials are typically made from durable materials like PVC or polypropylene, which offer resistance to corrosion, UV degradation, and mechanical wear, ensuring long-lasting performance.

7.Space Efficiency:

Cooling tower fills are designed to maximize the use of available space, allowing cooling towers to operate effectively without requiring excessive physical space.

8.Cost-Effective:

By improving heat transfer efficiency and reducing water consumption, fill materials can lead to lower operational costs, contributing to overall cost-effectiveness in cooling tower operation.

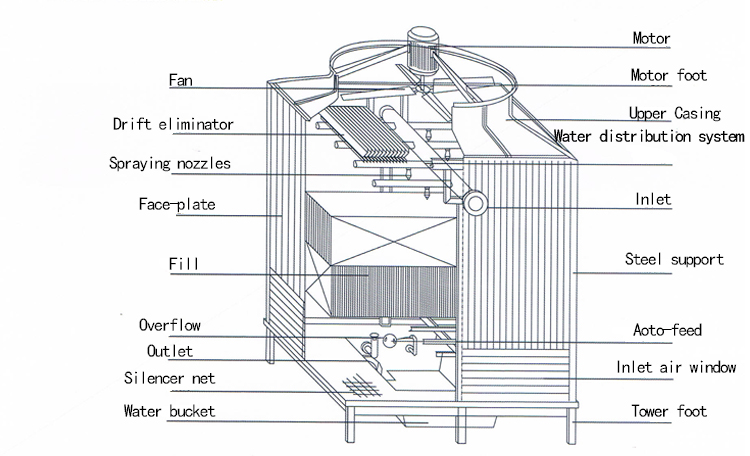

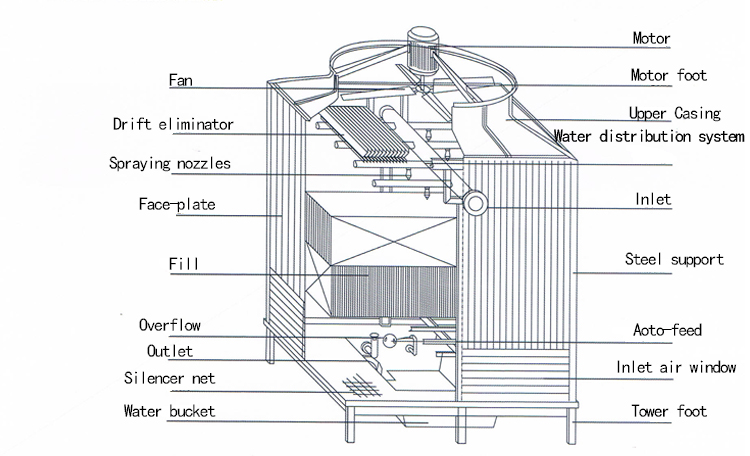

Structural Diagram of Fill In Cooling Tower

TOP 5 Cooling Tower Fill Manufacturers in Japan

1) Power Tower Cooling Technology (Shaoxing) Co.,Ltd.

PT is an excellent domestic manufacturer of cooling tower parts. Since its establishment in 2009, PT has always adhered to the concept of "long-lasting quality and endless innovation". PT produces various cooling tower fills, such as S-wave fills, cross-flow tower fills, counter flow tower fills,round fills. Various brand fills: Liangchi, Lanxun, Spindle, Ebara, Kingsun, etc. Materials include PP, PVC, UPVC.

The company has over 40 product inventions practical technology patents, and has iS09001, 1S014000, and other certifications.

PT company also can customize fillers according to your size requirements

2) Tsukishima Kankyo Engineering Co., Ltd.

Short intro — Tsukishima Kankyo is a Japanese engineering manufacturer with a long history in packed-column internals and specialty plastic fills. They develop and manufacture plastic ring fills (branded SPIRAX) and other structured/semi-structured fills tailored to gas-liquid contact applications — these products are widely used in absorption towers, water-treatment contactors and in industry processes, and the company supplies tower internals and fill modules for cooling / contact applications. Their product pages describe multiple packing families (SPIRAX, Raschig Super-Ring, Raschig Super-Pak, etc.) and tower internals.

3) Mitsubishi Chemical Infratec Co., Ltd.

Short intro — Mitsubishi Chemical Infratec (Mitsubishi Chemical group) manufactures complete cooling towers and explicitly promotes its original filling material “HISHI PACKING” (proprietary structured film fill) designed to provide large gas-liquid contact area and high cooling efficiency. Mitsubishi positions its fill as a key performance element of their “Hishi Cooling Tower” product family and highlights energy-saving / compact designs that depend on their filling material.

4) Kobe Steel / Kobelco Eco-Solutions Co., Ltd.

Short intro — Kobelco Eco-Solutions (part of Kobe Steel group) is a major Japanese cooling-tower supplier with thousands of installations. Technical papers and product docs from the company describe in-house development of new types of fill (for example, a “non-adhesive suspended-type” and other advanced fills, sometimes referred to generically as “hyper” / new-type fills in their R&D literature) and note their preference for film-type fills for many industrial applications. Kobelco provides fill replacement and retrofit services as part of its tower business.

5) Yamato Taiyo Co., Ltd.

Short intro — Yamato Taiyo is a Japanese specialist manufacturer of liquid/gas contact fills and water-treatment packing. Their Alpackin® family (PVC structured sheets) is explicitly marketed for cooling-tower fills (counterflow and cross-flow types), drift eliminators and spray/distribution fills. The site lists detailed product types, dimensions and media characteristics — a clear domestic fill-manufacturer example.

5) KUKEN (Kuken Industries Co., Ltd.) — Cooling-tower manufacturer that produces and supplies PVC sheet fills and replacement fill modules

Short intro — KUKEN is a long-established Japanese cooling-tower maker that both manufactures complete towers and supplies the key internal components (they explicitly list PVC-formed film fills / scatter/distribution fills on their maintenance & product pages). Kuken also documents maintenance and filler-exchange services — i.e., they supply manufactured fill modules for replacement and upgrades.