Compression molding process, is the current advanced manufacturing processof FRP Cooling Tower Panels, it uses impregnated film material as raw material, the product pressedby hydraulic press for power, first of all, a certain amount of molding material placedin the metal mold, and then in 150-170'c temperature and 1500-4000 tons of pressuremolding, the product size is accurate, the surface is smooth, and the product size isaccurate. lt can be formed once, the production efficiency is high, and the productquality is stable, suitable for mass production of various FRP products.

FRP Cooling Tower Panels Specification

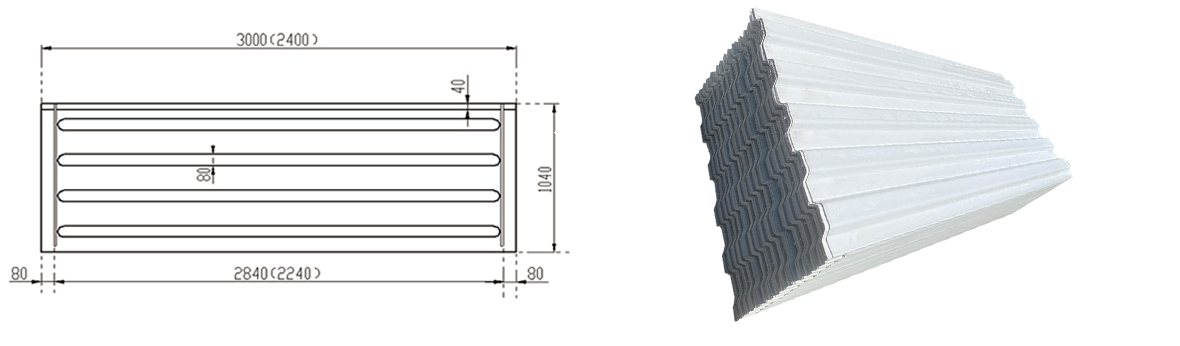

ABLZ-18-50 # Mold pressing (bearing straight air duct) parameters

| No. | Model | Length mm | Width mm | Average thickness mm | Quadrilateral thickness mm | Overlap with mm |

| 1 | ABM | Any | 1040 | 3 | 4 | 40 |

Note: The width ofthe casing is 1040mm, of which 40mm is the overlap surface, so the netsize ofthe casing afterinstallation is l meter per piece.

When to Choose FRP Cooling Tower Panels

I. Situations for Selecting FRP Cooling Tower Panels

Fiberglass panels for cooling towers, typically referring to the outer shell, tower structure, or other components made of fiberglass-reinforced plastic (FRP), are increasingly used in cooling tower applications. The choice of fiberglass panels mainly depends on the following aspects:

(1) FRP Cooling Tower Panels Corrosion Resistance Requirements

-

FRP Cooling Tower Panels With Harsh Chemical Environments

During the operation of cooling towers, they may come into contact with various chemicals such as acids, alkalis, and salts. Fiberglass panels offer excellent corrosion resistance, effectively withstanding the erosion of these chemicals to extend the service life of the cooling tower. For example, in chemical plants or power plants, the cooling water may contain corrosive substances, and fiberglass panels can provide better protection. -

FRP Cooling Tower Panel With Seawater Environments

For cooling towers located near the ocean or using seawater as a cooling medium, fiberglass panels can resist seawater corrosion, preventing the tower structure from being damaged by seawater.

(2) FRP Cooling Tower Panels Strength and Stability Requirements

-

FRP Cooling Tower Panels High Wind Pressure Environments

In regions with high wind pressure (such as coastal areas or areas with strong winds), cooling towers need to withstand significant wind pressure. Fiberglass panels have high strength and good wind resistance, ensuring the stability of the cooling tower under adverse weather conditions. -

FRP Cooling Tower Panels Large Cooling Towers

For large cooling towers, the structure needs to support considerable self-weight and operational loads. Fiberglass panels are not only strong but also lightweight, effectively reducing the overall weight of the cooling tower while ensuring structural stability.

(3) FRP Cooling Tower Panels Maintenance and Service Life

-

FRP Cooling Tower Panels Low Maintenance Costs

Fiberglass panels have a smooth surface that is less likely to accumulate dirt and algae, making cleaning and maintenance relatively simple. Additionally, fiberglass materials have good aging resistance, maintaining a good appearance and performance over long-term use, reducing maintenance costs. -

FRP Cooling Tower Panels Long Service Life

The service life of fiberglass panels is usually longer than that of traditional materials (such as metals or wood). Under normal use and maintenance conditions, fiberglass panels can last for decades, reducing the frequency of cooling tower replacements.

(4) FRP Cooling Tower Panels Design Flexibility and Aesthetics

-

FRP Cooling Tower Panels Customization

Fiberglass panels can be customized according to the specific design requirements of the cooling tower, including shape, size, and color. This customization capability allows the cooling tower to better adapt to different architectural environments and aesthetic requirements. -

FRP Cooling Tower Panels Aesthetics

Fiberglass panels can be designed in various colors and surface textures, which can coordinate with the surrounding environment or architectural style, enhancing the overall aesthetics of the cooling tower.

(5) FRP Cooling Tower Panels Fire Resistance and Environmental Requirements

-

FRP Cooling Tower Panels Fire Resistance

Fiberglass materials have good fire resistance, meeting the fire safety requirements of cooling towers in specific environments. For example, in industrial areas or city centers, cooling towers need to comply with strict fire safety standards, and fiberglass panels can be an ideal choice. -

FRP Cooling Tower Panels Environmental Friendliness

The production and use of fiberglass materials have a relatively small impact on the environment. Additionally, the long service life of fiberglass panels reduces material replacements and waste generation.

II. Performance Features of FRP Cooling Tower Panels in Cooling Towers

(1) FRP Cooling Tower Panels Corrosion Resistance

The main components of fiberglass panels are glass fibers and resin, which can effectively resist chemical corrosion. During the operation of cooling towers, the cooling water may contain various chemicals such as acids, alkalis, and salts. Fiberglass panels can withstand the erosion of these chemicals, extending the service life of the cooling tower.

(2) FRP Cooling Tower Panels High Strength and Lightweight

Fiberglass panels are made from high-strength glass fibers and resin composites, offering high mechanical strength. At the same time, the density of fiberglass materials is relatively low, making the panels lightweight while ensuring strength. This is significant for the overall structural design and installation of cooling towers, especially in large cooling towers or high wind pressure environments.

(3) FRP Cooling Tower Panels Good Aerodynamic Performance

The smooth surface of fiberglass panels can effectively reduce air resistance and improve the aerodynamic performance of the cooling tower. This helps enhance the cooling efficiency of the cooling tower while reducing energy consumption.

(4) FRP Cooling Tower Panels Aging and UV Resistance

Fiberglass panels are typically coated with a special protective layer that can resist UV radiation, preventing material aging and discoloration. This ensures that fiberglass panels maintain a good appearance and performance over long-term use, especially in outdoor environments.

(5) FRP Cooling Tower Panels Fire Resistance

Fiberglass materials have good fire resistance, meeting the fire safety requirements of cooling towers in specific environments. This makes fiberglass panels an ideal choice in places with strict fire safety requirements, such as chemical plants and power plants.

III. Key Considerations for Selecting FRP Cooling Tower Panels

(1) FRP Cooling Tower Panels Based on the Type and Specifications of the Cooling Tower

-

Counterflow Cooling Towers

The panels for counterflow cooling towers need to have good aerodynamic performance and strength to adapt to complex airflow organization. Fiberglass panels can meet these requirements while providing excellent corrosion resistance. -

Crossflow Cooling Towers

The panel design for crossflow cooling towers is relatively simpler but needs to consider the characteristics of horizontal airflow. Fiberglass panels can effectively guide airflow while providing sufficient strength and corrosion resistance.

(2) FRP Cooling Tower Panels Based on Operating Environment

-

FRP Cooling Tower Panels Chemical Environment

If the cooling tower operates in an environment with harsh chemicals (such as chemical plants or electroplating factories), fiberglass panels are an ideal choice as they can withstand chemical erosion. -

FRP Cooling Tower Panels Climate Conditions

In environments with high wind pressure, high humidity, or strong UV radiation, the weather resistance and aging resistance of fiberglass panels can ensure the long-term stable operation of the cooling tower.

(3) FRP Cooling Tower Panels Based on Maintenance and Service Life Requirements

-

FRP Cooling Tower Panels Low Maintenance Costs

Fiberglass panels have a smooth surface that is less likely to accumulate dirt and algae, making cleaning and maintenance relatively simple. Additionally, the good aging resistance of fiberglass materials can maintain a good appearance and performance over long-term use, reducing maintenance costs. -

FRP Cooling Tower Panels Long Service Life

The service life of fiberglass panels is usually longer than that of traditional materials (such as metals or wood). Under normal use and maintenance conditions, fiberglass panels can last for decades, reducing the frequency of cooling tower replacements.

(4) FRP Cooling Tower Panels Based on Design Flexibility and Aesthetic Requirements

-

FRP Cooling Tower Panels Customization

Fiberglass panels can be customized according to the specific design requirements of the cooling tower, including shape, size, and color. This customization capability allows the cooling tower to better adapt to different architectural environments and aesthetic requirements. -

FRP Cooling Tower Panels Aesthetics

Fiberglass panels can be designed in various colors and surface textures, which can coordinate with the surrounding environment or architectural style, enhancing the overall aesthetics of the cooling tower.

IV. Installation and Maintenance of FRP Cooling Tower Panels

(1) FRP Cooling Tower Panels Installation Steps

-

FRP Cooling Tower Panels Inspect the Panels

Before installation, carefully inspect the fiberglass panels for any damage or deformation to ensure their integrity. -

FRP Cooling Tower Panels Adjust Installation Position

According to the design requirements of the cooling tower, adjust the installation position of the panels to ensure they are correctly installed and functional. -

FRP Cooling Tower Panels Secure the Panels

Use dedicated fastening devices to securely install the panels on the cooling tower, ensuring they do not loosen during operation.

(2) FRP Cooling Tower Panels Maintenance Tips

-

FRP Cooling Tower Panels Regular Inspection

Regularly inspect the fiberglass panels for any damage, deformation, or loosening, and promptly repair or replace any damaged panels. -

FRP Cooling Tower Panels Cleaning and Maintenance

Regularly clean the surface of the fiberglass panels to remove dust and dirt, maintaining their aerodynamic performance and appearance. Soft cloths or water can be used for cleaning, avoiding the use of corrosive cleaning agents. -

FRP Cooling Tower Panels Check Protective Layer

Regularly inspect the protective layer on the surface of the panels to ensure it is intact. If damage is found, it should be repaired promptly to prevent UV radiation and chemical erosion of the panels.

FRP Cooling Tower Panels Features

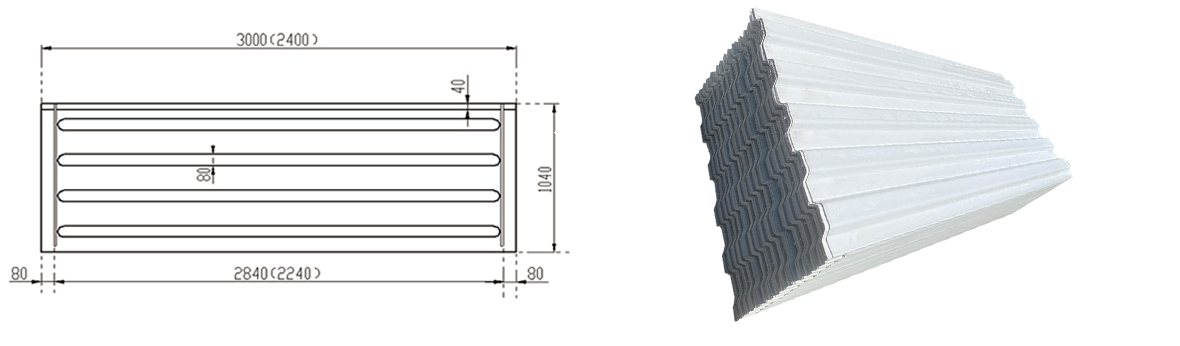

This product is a standardized product with high production efficiency,facilitating fast, large-scale production,and automated production.

The products produced by the molding process have high dimensional accuracy, no need to cut the edges,no deformation, and very convenient installation.

The interal and external surfaces of the product are smooth and contain anti UV agents, which have strong weather resistance and do not require secondary modification.

The product has a reasonable structural design, high vibration resistance, andeffectively avoids vibration.

The product is high-temperature pressed,therefore the product has high density,standardized molding, and no defects

FRP Cooling Tower Panels Application

The application range is: Industrial water cooling,Air compressor, Aluminum profile processing, Steam turbine, Power generation, Tannery, Electric furnace, Freezing Series, Air conditioning cooling system

FRP Cooling Tower Panels Shipment

Packing:

Wooden,cartons,custom package.

Delivery time:

With in 10 days.

Our Services Of FRP Cooling Tower Panels

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.