The cooling tower air intake louver is made of high-strength PVC board and bonded. Advanced honeycomb grille design can improve the airflow into the cooling tower, effectively filter impurities and prevent water splashing.

Cooling Tower Air Inlet Louver Specification

The water collector removes the small water droplets carried in the waste gas. If they are allowed to escape through the top of the tower together with the heated air, the harm and health problems will be minimized. The drift eliminator is designed to create a tortuous path for air flow. When the water drops pass through them, they are forced to change direction, hit the side wall of the drift eliminator, aggregate and discharge back to the wet section of the cooling tower.

| W | H | L | Gap | Angle |

| 25 multiple | 85 | Any | 25 | 90° |

When To Replace The Cooling Tower Air Inlet Louver

The timing for replacing the cooling tower intake louver usually depends on its degree of damage, usage environment, and maintenance conditions. Here are some situations when the cooling tower intake louver needs to be replaced:

1. Cooling Tower Air Inlet Louver Damage or Deformation

-

If the intake louver shows obvious damage, such as cracks, deformation, or missing parts, it will affect its normal functions, like blocking debris and guiding airflow. It should be replaced promptly.

-

If the blades or frame of the louver are corroded or aged to the point where the structure is unstable, replacement is also necessary.

2. Cooling Tower Air Inlet Louver Blockage or Scaling

-

After long-term use, the intake louver may be clogged by dust, debris, or scale, leading to poor ventilation and reduced cooling efficiency of the cooling tower. If cleaning does not restore its performance, replacement should be considered.

-

During winter operation, if the intake louver becomes frozen due to low temperatures, causing ventilation blockage or damage, it needs to be replaced.

3. Cooling Tower Air Inlet Louver Maintenance Cycle

-

Although there is no fixed replacement cycle, it is recommended to check the condition of the intake louver during the regular maintenance of the cooling tower. Generally, if other components of the cooling tower (such as packing) need to be replaced, the intake louver should also be checked to see if it needs replacement.

4. Cooling Tower Air Inlet Louver Impact on Cooling Effectiveness

-

If the angle, number of blades, or positioning of the intake louver is not appropriate, causing the air to not flow evenly towards the cooling coils, or placing the cooling coils in a vortex area, which affects cooling effectiveness, replacement should be considered.

5. Cooling Tower Air Inlet Louver Other Situations

-

If the material of the intake louver is not suitable for the usage environment, for example, using a common material in a highly corrosive environment, which may accelerate aging, it should be replaced with a more corrosion-resistant material.

In summary, regularly inspecting the condition of the intake louver and replacing it in a timely manner according to the actual situation can effectively extend the service life of the cooling tower and maintain its good operating condition.

Cooling Tower Air Inlet Louver Features

Prevent sundries from entering.

Prevent water droplets from splashing.

Limit the amount of sunlight entering the cooling tower (to prevent algae growth).

Reduce the noise in the tower.

And a very low pressure drop effect is achieved.

Convenient installation, cleaning and maintenance.

Widely used in a variety of new and refurbished applications, including the air inlet of two packages. And the counter-current and straight-side cross-flow tower, fresh air supplement system and air pollution control scrubber installed on site.

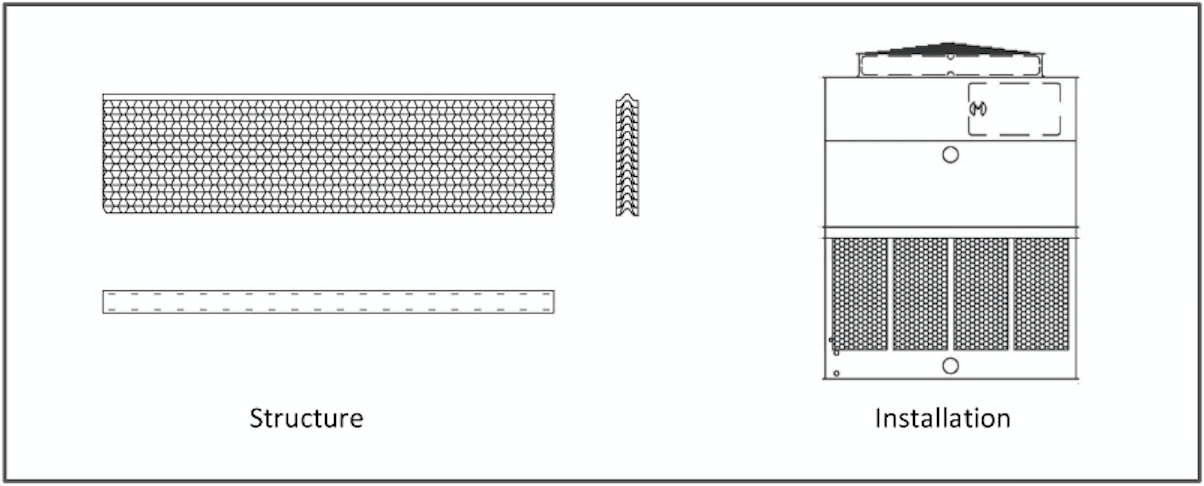

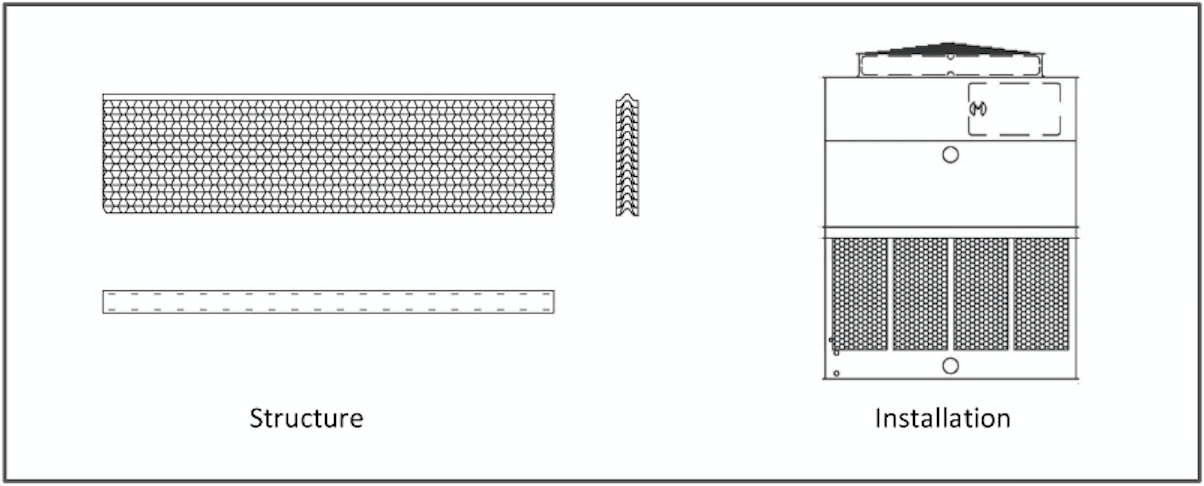

Cooling Tower Air Inlet Louver Structural installation drawing

The structural position of the Cooling Tower Air Inlet Louver is shown in the following figure.

Please tell us the model or size of the cooling tower, and we will estimate the number of sheets needed to replace the cooling tower.

Cooling Tower Air Inlet Louver Application

The application range of cooling tower PVC fills is: Industrial water cooling,Air compressor, Aluminum profile processing, Steam turbine, Power generation, Tannery, Electric furnace, Freezing Series, Air conditioning cooling system

Selecting The Appropriate PVC Cooling Tower Air Inlet Louver

Selecting the appropriate PVC Cooling Tower Air Inlet Louver requires a comprehensive consideration of factors such as the type of cooling tower, working environment, technical parameters, and material properties. Here is a detailed guide for selection:

1. Cooling Tower Type and PVC Cooling Tower Air Inlet Louver Design

-

PVC Cooling Tower Air Inlet Louver For Crossflow Cooling Towers:

For crossflow cooling towers, the inlet typically requires louvers to prevent debris from entering and to optimize airflow distribution. The louver design should effectively filter out impurities while minimizing water splash. -

PVC Cooling Tower Air Inlet Louver For Counterflow Cooling Towers:

Counterflow cooling towers may not require louvers at the inlet, but in areas with high winds, sand, or floating debris, it is advisable to install louvers or protective screens. If louvers are installed, their height should be determined based on the ratio of the inlet area to the fill area.

2. PVC Cooling Tower Air Inlet Louver Technical Parameters

-

PVC Cooling Tower Air Inlet Louver Inlet Area and Air Velocity:

The average air velocity at the inlet should be selected according to the type and design requirements of the cooling tower. For example, in crossflow cooling towers, the average air velocity at the inlet should be between 1.8 m/s and 3.3 m/s. The height and area ratio of the inlet should also be designed reasonably to ensure sufficient airflow. -

PVC Cooling Tower Air Inlet Louver Ventilation Resistance:

The total ventilation resistance loss at the inlet (Z△P) should be controlled within a reasonable range. When the pressure ratio (P) is less than 5, design parameters should be adjusted. -

PVC Cooling Tower Air Inlet Louver Drift Rate:

The drift rate of the cooling tower should not exceed 0.010%. The design of the inlet louvers should help reduce water droplet splash.

3. PVC Cooling Tower Air Inlet Louver Material Properties

-

PVC Cooling Tower Air Inlet Louver Corrosion Resistance:

The materials used for inlet louvers should have good corrosion resistance, especially in environments where the cooling water contains corrosive substances. Common materials include high-strength PVC sheets, galvanized steel, or stainless steel. -

PVC Cooling Tower Air Inlet Louver Strength and Lifespan:

The materials should have sufficient strength and durability to withstand long-term outdoor use. For example, PVC materials can have a lifespan of over 15 years. -

PVC Cooling Tower Air Inlet Louver Algae Prevention:

The design of the inlet louvers should limit direct sunlight exposure to the cooling tower sump to prevent algae growth.

4. PVC Cooling Tower Air Inlet Louver Installation and Maintenance

-

PVC Cooling Tower Air Inlet Louver Ease of Installation:

Inlet louvers should be easy to install and remove for routine maintenance and inspection. For example, some new louver designs can be simply pushed into the cooling tower and secured, making installation very convenient. -

PVC Cooling Tower Air Inlet Louver Maintenance Requirements:

Choose louvers that are easy to clean and maintain to reduce routine maintenance workload. For example, PVC material louvers are easy to clean and do not require additional corrosion protection.

5. PVC Cooling Tower Air Inlet Louver Environmental Adaptability

-

PVC Cooling Tower Air Inlet Louver Wind Direction and Layout:

The inlet side of the cooling tower should face the prevailing wind direction in summer to optimize airflow conditions. If there is an angle between the inlet and the prevailing wind direction, it is recommended to install side deflectors at the end of the tower row. -

PVC Cooling Tower Air Inlet Louver Surrounding Environment:

The cooling tower should be located away from heat sources and exhaust outlets to prevent recirculation of warm, humid air that could affect cooling efficiency. The distance between the inlet side and buildings should be more than twice the height of the tower inlet.

6. PVC Cooling Tower Air Inlet Louver Special Requirements

-

PVC Cooling Tower Air Inlet Louver Noise Control:

If the cooling tower is installed in a noise-sensitive area, it is advisable to select inlet louvers with noise reduction features. -

PVC Cooling Tower Air Inlet Louver Customization:

Inlet louvers can be customized according to the specific dimensions and requirements of the cooling tower to meet special application scenarios.

7. PVC Cooling Tower Air Inlet Louver Standards and Regulations

-

PVC Cooling Tower Air Inlet Louver Compliance with National Standards:

The design and materials of the inlet louvers should comply with relevant national standards, such as the "Code for Process Design of Mechanical Draft Cooling Towers" (GB/T 50392-2016). -

PVC Cooling Tower Air Inlet Louver Performance Testing:

Material properties should be tested by professional organizations, such as SGS testing and ASTM standards, to ensure their quality and reliability.

By comprehensively considering the above factors, the appropriate inlet louvers can be selected for the cooling tower to optimize its performance and service life.

PVC Cooling Tower Air Inlet Louver Shippment

Packing:

Wooden,cartons,custom package

Delivery time:

With in 10 days.

Our Services Of PVC Cooling Tower Air Inlet Louver

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.