FRP Molded Cooling Tower Louvers Overview

FRP molded cooling tower louvers are essential for optimizing airflow, enhancing cooling efficiency, and protecting internal tower components from environmental factors. Made from fiberglass-reinforced plastic (FRP), these louvers offer exceptional corrosion resistance, lightweight strength, and long-term durability, making them ideal for industrial and commercial cooling towers.

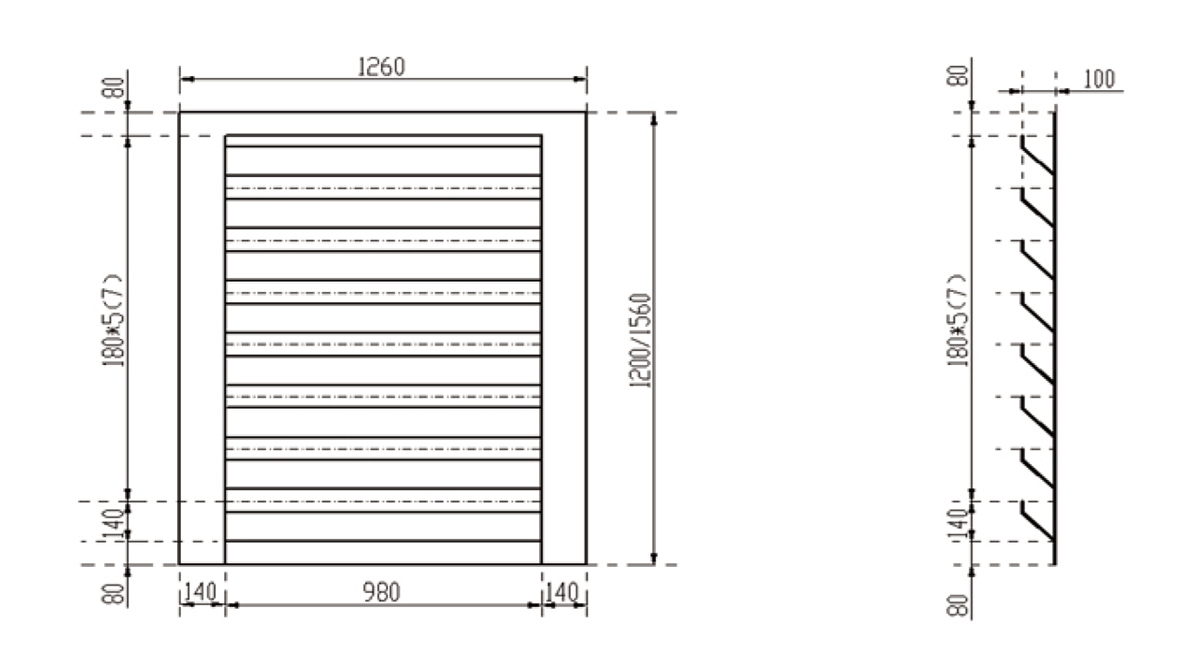

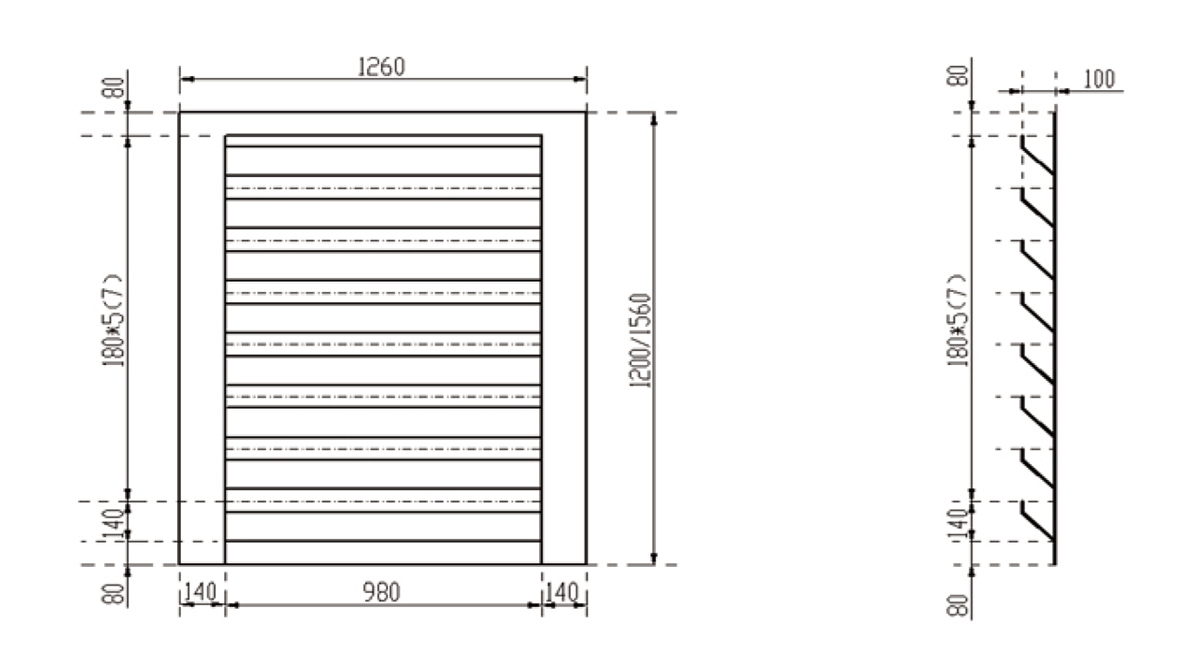

FRP Molded Cooling Tower Louvers Specifications

Our louvers are customizable in size and configuration to meet specific cooling tower requirements. Height can be adjusted by overlapping or cutting, and width can be widened by splicing.

| No. | Model | Wave Height (mm) | Inner Width (mm) | Overlap Surface Width (mm) | Total Width (mm) | Thickness (mm) | Height (mm) |

| 1 | ABY-156 | 100 | 980 | 140 | 1080-2260 | 2.5-3.0 | 1560 |

| 2 | ABY-120 | 100 | 980 | 140 | 1080-2260 | 2.5-3.0 | 1200 |

Note: Louvers are customizable. Height can be increased by overlapping or reduced by cutting. Width can be widened by splicing.

When to Use FRP Molded Cooling Tower Louvers

FRP louvers are ideal for specific conditions where their unique properties enhance cooling tower performance and longevity.

Corrosive Environments

Chemical Exposure: Ideal for chemical plants and refineries due to resistance to acids, alkalis, and salts.

Saltwater Environments: Withstands corrosion in coastal or seawater-based cooling systems.

High Humidity Conditions

Moisture Resistance: Unaffected by humidity, preventing rust and degradation.

Algae Prevention: Smooth surfaces resist algae buildup, maintaining efficiency.

High Wind Pressure Areas

Noise Reduction Requirements

Customization and Aesthetic Needs

Design Flexibility: Customizable in size, shape, and color for architectural integration.

Aesthetic Appeal: Smooth finishes enhance visual appeal.

Maintenance and Longevity

Fire Resistance

Weight Considerations

Energy Efficiency

Improved Airflow: Optimizes fan efficiency, reducing energy costs.

Reduced Fan Load: Minimizes air resistance for lower motor wear.

Key Features of FRP Molded Cooling Tower Louvers

High Production Efficiency: Standardized molding for fast, large-scale production.

Precision Manufacturing: High dimensional accuracy with smooth edges, no deformation, and easy installation.

UV Resistance: Anti-UV agents ensure durability and appearance in outdoor conditions.

Vibration Resistance: Robust structural design minimizes vibration.

High Density: High-temperature pressing ensures defect-free, durable louvers.

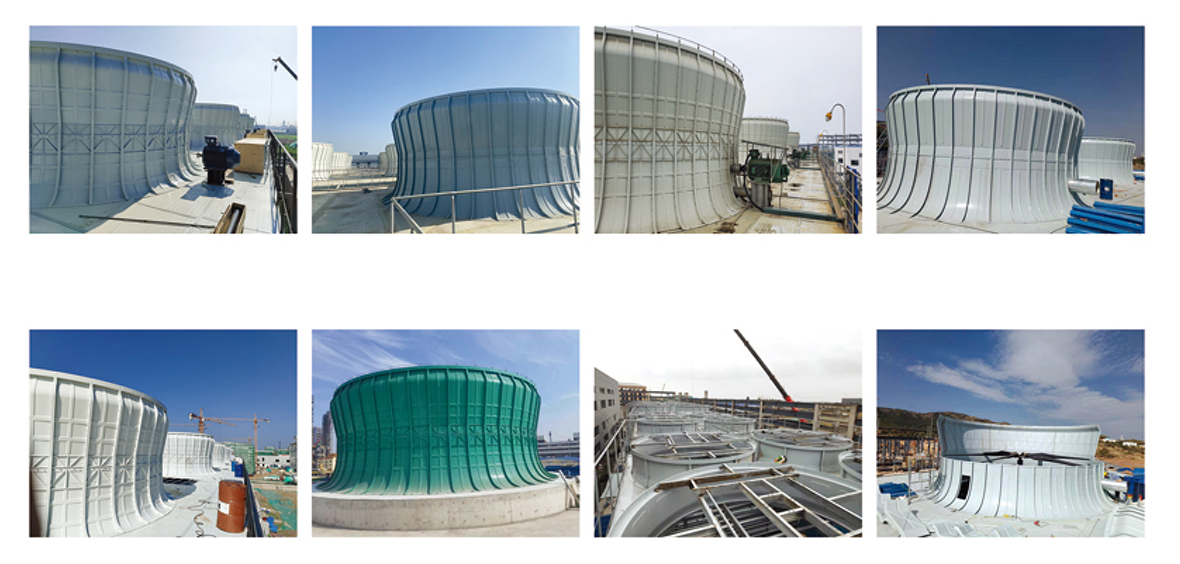

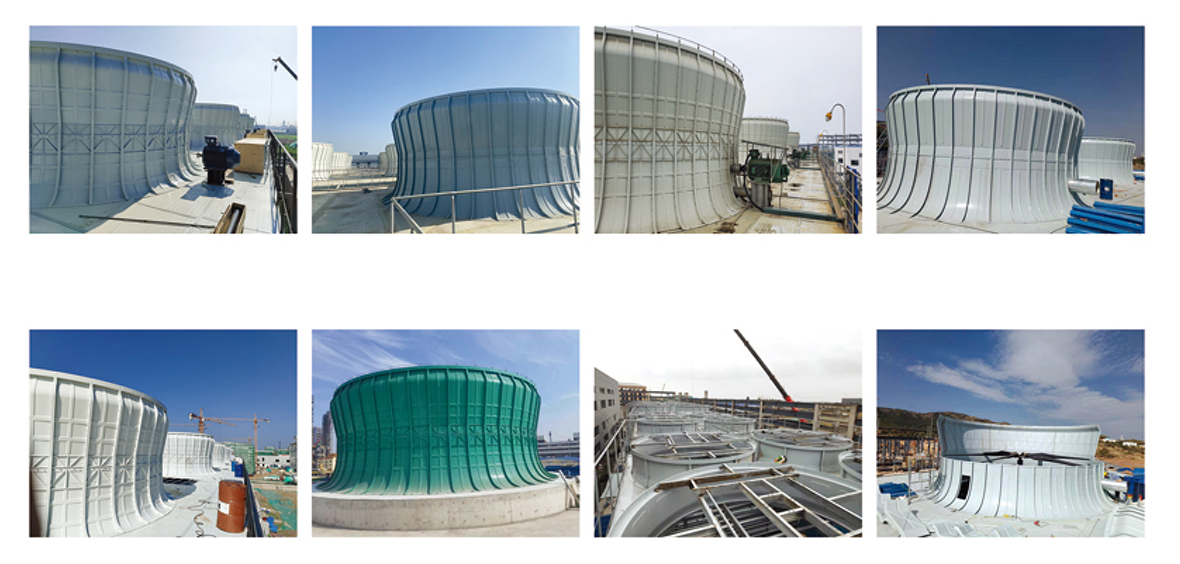

Applications of FRP Molded Cooling Tower Louvers

FRP louvers are used in industries such as:

Packaging and Shipping

Packaging

Packaged in wooden crates, cartons, or customized per request.

Delivery Time

Shipped within 10 days.

Our Services for FRP Molded Cooling Tower Louvers

Pre-Sale Services

We provide product images, videos, quotations, and engineering drawings tailored to your needs. Factory visits are welcome.

Sale Services

Production schedule updates with photos.

24/7 support via phone, email, or online services.

On-site installation guidance and training available.

After-Sale Services

12-month warranty with ongoing support to ensure optimal performance.

About PT

With over 20 years of experience, PT is a trusted global supplier of cooling tower components. Our expertise ensures high-quality, reliable solutions for industries worldwide. Request a Quote to explore how we can meet your cooling needs.

Frequently Asked Questions (FAQ)

What is the purpose of FRP molded cooling tower louvers?

They optimize airflow, enhance cooling efficiency, and protect internal components from environmental factors.

Why choose FRP louvers over metal ones?

FRP louvers are corrosion-resistant, lightweight, and require less maintenance than metal alternatives.

Can FRP louvers be customized?

Yes, size, shape, and color can be tailored, with adjustable height and width options.

Are FRP louvers suitable for coastal environments?

Yes, their corrosion resistance makes them ideal for saltwater and high-humidity conditions.

How do FRP louvers contribute to energy efficiency?

They optimize airflow and reduce fan load, lowering energy consumption.

What is the lifespan of FRP cooling tower louvers?

With UV and corrosion resistance, they last over 10 years with minimal maintenance.

What industries use FRP cooling tower louvers?

Power generation, chemical processing, HVAC, and more.

What is the delivery time for FRP louvers?

Orders are delivered within 10 days.

Why Choose PT for FRP Molded Cooling Tower Louvers?

Premium Quality: Made with imported raw materials for durability.

Competitive Pricing: Flexible pricing tailored to market demands.

Expertise: Over 20 years of experience in cooling tower solutions.

Superior Service: Comprehensive support with a 12-month warranty.