Molded FRP Cooling Tower Spray Pan Specification

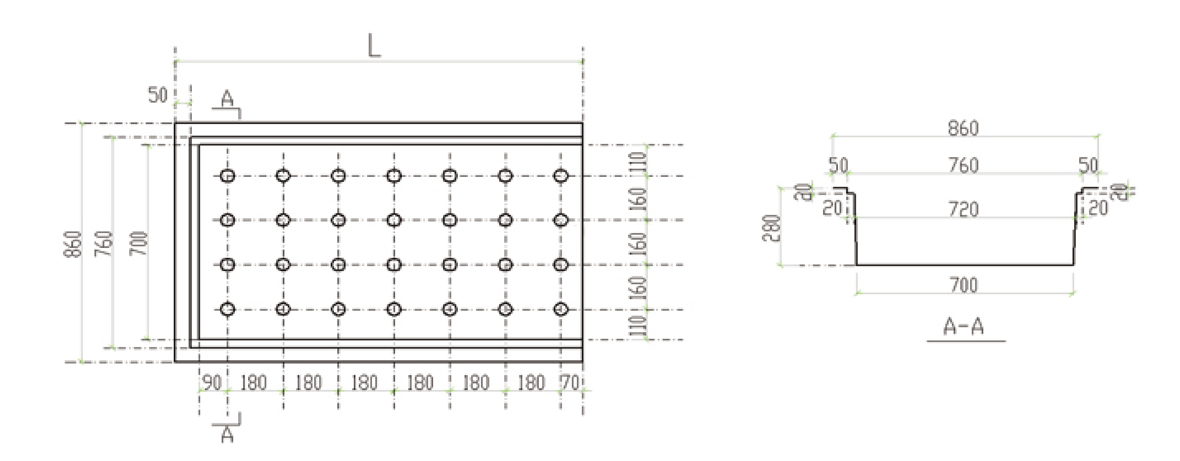

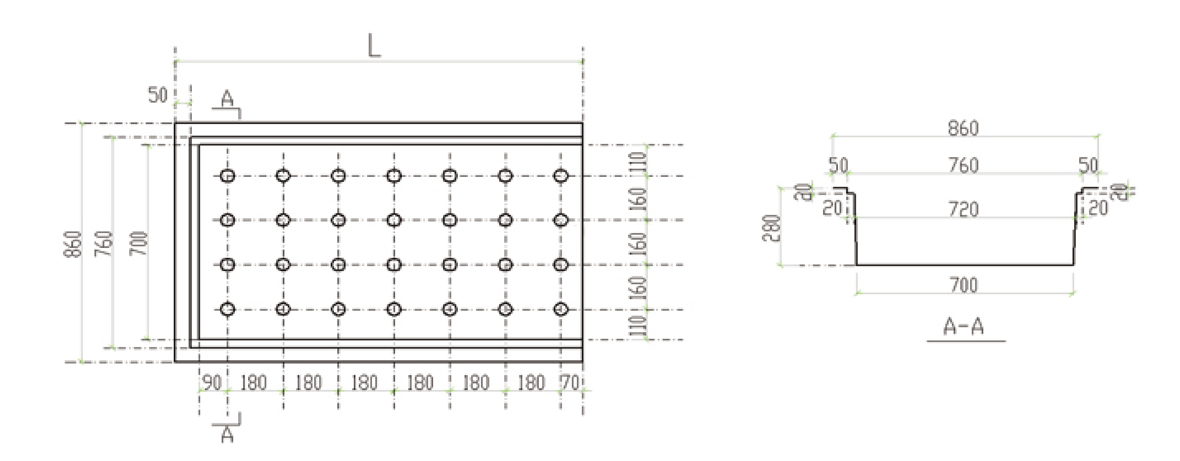

| No. | Model | Wave channel depth mm | Nozzle aperture mm | Bottom width mm | Top width mm | L mm |

| 1 | ABS-16 | 280 | 45 | 700 | 860 | 1600 |

2

| ABS-132 | 280 | 45 | 700 | 860 | 1320 |

| 3 | ABS-100 | 280 | 45 | 700 | 860 | 1000 |

Note: 1.Length can be made according to user requirements.

When to Use Molded FRP Cooling Tower Spray Pan

Fiberglass Reinforced Plastic (FRP) water distribution pans are an essential component in cooling tower systems, particularly when specific operational conditions or environmental factors need to be addressed. Here are the key situations where FRP water distribution pans are particularly beneficial:

1. Molded FRP Cooling Tower Spray Pan Corrosive Environments

-

Molded FRP Cooling Tower Spray Pan Chemical Exposure:

Cooling towers in industrial settings, such as chemical plants, refineries, or power plants, often operate in environments with corrosive substances. FRP water distribution pans are highly resistant to chemical corrosion, making them ideal for these applications. -

Molded FRP Cooling Tower Spray Pan Saltwater Environments:

For cooling towers located near coastal areas or those using seawater as a cooling medium, FRP pans can withstand the corrosive effects of saltwater, ensuring long-term durability.

2. Molded FRP Cooling Tower Spray Pan High Humidity Conditions

-

Molded FRP Cooling Tower Spray Pan Moisture Resistance:

In high humidity environments, metal components may be prone to rust and degradation over time. FRP water distribution pans are not affected by moisture, maintaining their structural integrity and performance even in damp conditions. -

Molded FRP Cooling Tower Spray Pan Prevention of Algae Growth:

FRP surfaces are less likely to support the growth of algae and other microorganisms, which can be a problem in humid environments. This helps in maintaining the cleanliness and efficiency of the cooling tower.

3. Molded FRP Cooling Tower Spray Pan High Water Quality Requirements

-

Molded FRP Cooling Tower Spray Pan Uniform Water Distribution:

FRP water distribution pans are designed to ensure uniform distribution of water across the cooling tower fill. This is crucial for maintaining consistent cooling efficiency and preventing localized overheating or undercooling. -

Molded FRP Cooling Tower Spray Pan Reduced Water Splash:

The design of FRP pans can effectively reduce water splash, minimizing water loss and improving overall cooling efficiency.

4. Molded FRP Cooling Tower Spray Pan Maintenance and Longevity

-

Molded FRP Cooling Tower Spray Pan Low Maintenance:

FRP materials require minimal maintenance compared to traditional metal components. They do not need painting or rust-proofing, reducing the overall maintenance costs over the life of the cooling tower. -

Molded FRP Cooling Tower Spray Pan Extended Service Life:

The durability and resistance to environmental degradation of FRP materials mean that water distribution pans made from FRP have a longer service life. This reduces the frequency of replacements and associated downtime.

5. Molded FRP Cooling Tower Spray Pan Weight Considerations

-

Molded FRP Cooling Tower Spray Pan Lightweight Design:

FRP water distribution pans are significantly lighter than their metal counterparts. This can be an important consideration in the overall structural design of the cooling tower, especially for large or tall towers where weight reduction can lead to cost savings in structural support systems. -

Molded FRP Cooling Tower Spray Pan Ease of Installation:

The lightweight nature of FRP pans makes them easier to handle and install, reducing the effort and time required during the construction or retrofitting of cooling towers.

6. Molded FRP Cooling Tower Spray Pan Customization and Aesthetic Requirements

-

Molded FRP Cooling Tower Spray Pan Design Flexibility:

FRP water distribution pans can be customized in terms of size, shape, and color to match the specific design requirements of the cooling tower and its surrounding environment. This is particularly useful in architectural applications where the cooling tower needs to blend seamlessly with the building design. -

Molded FRP Cooling Tower Spray Pan Aesthetic Appeal:

FRP pans can be manufactured with smooth surfaces and various finishes, enhancing the overall appearance of the cooling tower. This is important in visible locations where the cooling tower is part of the architectural landscape.

7. Molded FRP Cooling Tower Spray Pan Fire Resistance

-

Molded FRP Cooling Tower Spray Pan Fire Safety:

In environments where fire safety is a critical concern, FRP water distribution pans can offer better fire resistance compared to some other materials. This is particularly important in industrial settings where the risk of fire is higher. -

Molded FRP Cooling Tower Spray Pan Compliance with Fire Codes:

Using fire-resistant materials like FRP can help cooling towers comply with local fire safety regulations and standards.

8. Molded FRP Cooling Tower Spray Pan Energy Efficiency

-

Molded FRP Cooling Tower Spray Pan Improved Water Flow:

FRP water distribution pans can be designed to optimize water flow, reducing the energy required to operate the cooling tower pumps. Efficient water distribution helps in lowering operational costs and improving the overall efficiency of the cooling system. -

Molded FRP Cooling Tower Spray Pan Reduced Pump Load:

By minimizing water resistance, FRP pans can reduce the load on the cooling tower pumps, leading to lower energy consumption and reduced wear and tear on pump motors.

Installation of Molded FRP Cooling Tower Spray Pan

I. Preparations Before Molded FRP Cooling Tower Spray Pan Installation

-

Inspect the Distribution Molded FRP Cooling Tower Spray Pan

Carefully examine the FRP water distribution pan for any damage, deformation, or cracks before installation. Ensure the surface is smooth and free from obvious defects. If any issues are found, repair or replace the pan promptly. -

Clean the Installation Area of Molded FRP Cooling Tower Spray Pan

Clear the installation area inside the cooling tower, ensuring there are no debris, dust, or other obstructions that could affect the installation. Pay special attention to the support structure and mounting points of the distribution pan, which must be clean and dry. -

Verify Dimensions and Specifications of Molded FRP Cooling Tower Spray Pan

Confirm that the dimensions and specifications of the distribution pan match the design requirements of the cooling tower. Check that the interfaces, connectors, and fastening devices of the pan are compatible.

II. Molded FRP Cooling Tower Spray Pan Installation Steps

-

Position the Distribution Molded FRP Cooling Tower Spray Pan

Place the FRP water distribution pan in the designated position within the cooling tower. Typically, the distribution pan is located at the top of the cooling tower, where it evenly distributes hot water onto the fill material. Align the center of the distribution pan with the center of the cooling tower according to the design drawings. -

Install the Support Structure of Molded FRP Cooling Tower Spray Pan

Install the support structure for the distribution pan. These supports are usually made of metal frames or FRP brackets, designed to hold the pan securely and bear its weight. Ensure the support structure is firmly installed, level, and stable. -

Secure the Distribution Molded FRP Cooling Tower Spray Pan

Use dedicated fastening devices (such as bolts, nuts, or clips) to secure the distribution pan to the support structure. Ensure the fastening devices are tightly installed and free from looseness. During installation, avoid applying excessive external force to the distribution pan to prevent damage. -

Connect the Water Pipes of Molded FRP Cooling Tower Spray Pan

Connect the inlet of the distribution pan to the hot water pipes of the cooling tower. Ensure the connections are well-sealed and leak-free. Typically, flanged or threaded connections are used, with gaskets installed at the connection points. -

Install Nozzles or Distributors of Molded FRP Cooling Tower Spray Pan

Install nozzles or distributors at the water outlets of the distribution pan. These components are used to evenly spray hot water onto the fill material. Ensure the nozzles or distributors are securely installed and correctly oriented to achieve optimal water distribution. -

Check Levelness of Molded FRP Cooling Tower Spray Pan

Use a level to check the levelness of the distribution pan after installation. Ensure the pan is level to guarantee even water distribution. If it is not level, adjust the support structure or fastening devices until the required levelness is achieved.

III. Post-Installation Checks and Commissioning

-

Check Sealing of Molded FRP Cooling Tower Spray Pan

After installation, conduct a sealing check. Open the inlet valve of the cooling tower and allow hot water to flow into the distribution pan. Check for any leaks, paying special attention to the seals at the connections and nozzles. -

Check Water Distribution of Molded FRP Cooling Tower Spray Pan

Observe the water distribution to ensure that hot water is evenly distributed across the fill material. If uneven distribution is observed, adjust the direction or position of the nozzles. -

Check Fastening Devices of Molded FRP Cooling Tower Spray Pan

Recheck the fastening devices of the distribution pan to ensure all bolts and connectors are securely tightened and free from looseness. -

Run a Test of Molded FRP Cooling Tower Spray Pan

Conduct a test run of the cooling tower to observe the performance of the distribution pan during actual operation. Check for any unusual noises, vibrations, or leaks. If any issues are detected, stop the system immediately for inspection and repair.

IV. Precautions

-

Avoid Impact of Molded FRP Cooling Tower Spray Pan

During installation, avoid applying impact forces to the FRP water distribution pan to prevent damage. Although FRP materials are strong, they should still be handled with care during installation. -

Regular Maintenance for Molded FRP Cooling Tower Spray Pan

After installation, regularly maintain and inspect the distribution pan. Clean the nozzles and distributors to ensure unobstructed water flow. Regularly check the tightness of the fastening devices to prevent loosening. -

Environmental Adaptability of Molded FRP Cooling Tower Spray Pan

Ensure that the installation environment meets the usage requirements of the FRP distribution pan. Avoid prolonged exposure to high temperatures, strong acids or alkalis, or high humidity to extend its service life.

By following the above steps and precautions, the FRP water distribution pan can be correctly installed and efficiently operated in the cooling tower, thereby enhancing the overall performance and service life of the cooling system.

Molded FRP Cooling Tower Spray Pan Application

The application range is: Industrial water cooling,Air compressor, Aluminum profile processing, Steam turbine, Power generation, Tannery, Electric furnace, Freezing Series, Air conditioning cooling system

Molded FRP Cooling Tower Spray Pan Shippment

Packing:

Wooden,cartons,custom package.

Delivery time:

With in 10 days.

Our Services Of Molded FRP Cooling Tower Spray Pan

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.