Marley Drift Eliminator in Cooling Tower Overview

Marley Drift Eliminators are critical components in cooling tower systems, designed to capture and recover water droplets generated during the cooling process. By minimizing drift loss, these eliminators enhance cooling efficiency, conserve water resources, and reduce environmental impact, making them essential for sustainable industrial operations.

Marley Drift Eliminator Specifications

Marley Drift Eliminators are customizable to suit various cooling tower models and operating conditions. Provide the tower model or dimensions, and we will estimate the number of sheets required for replacement.

| Width (mm) | Height (mm) | Length (mm) | Gap (mm) | Angle |

| 25 multiple | 145 | Any | 30 | 90° |

Material Options

High-performance PVC or FRP, enhanced with carbon black for UV resistance.

Key Features of Marley Drift Eliminator

High-Efficiency Water Collection

Low Drift Loss: Achieves drift loss as low as 0.001%, with patented SRC and MR series reaching 0.0005%.

Effective Droplet Capture: Optimized structure ensures efficient water recovery.

Low Airflow Resistance

Optimized Design: Fiber-reinforced composites reduce resistance, lowering fan energy consumption.

Enhanced Efficiency: Improves overall cooling tower performance.

Durable Materials and Structure

Integrated Design

Environmental and Energy Efficiency

Water Conservation: Minimizes water loss through efficient droplet capture.

Energy Reduction: Low-resistance design reduces operational costs.

Reduced Pollution: Minimizes environmental impact from water mist.

Low-Noise Operation

Adaptability to Various Cooling Towers

Easy Maintenance and Cleaning

Long Service Life and High Reliability

Compliance with International Standards

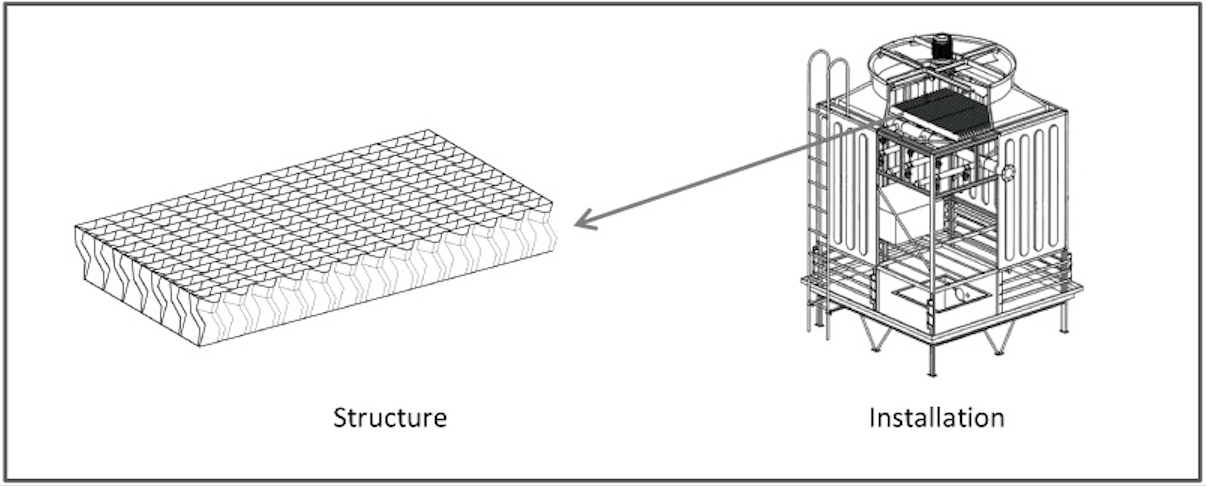

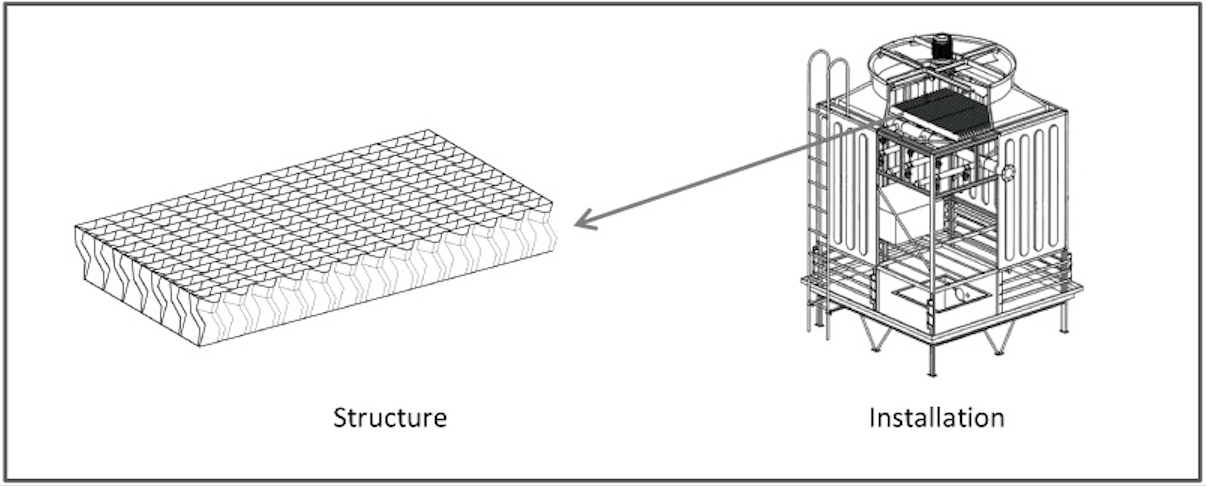

Structural Installation of Marley Drift Eliminator

The structural positioning of Marley Drift Eliminators is optimized for seamless integration. Refer to the diagram below for installation details.

Applications of Marley Drift Eliminator

Used in industries including:

Packaging and Shipping

Packaging

Packaged in wooden crates, cartons, or customized packaging to ensure safe delivery.

Delivery Time

Shipped within 10 days.

Our Services for Marley Drift Eliminator

Pre-Sale Services

We provide product images, videos, quotations, and engineering drawings tailored to your needs. Factory visits are welcome.

Sale Services

Production schedule updates with photos.

24/7 support via phone, email, or online services.

On-site installation guidance and training available.

After-Sale Services

12-month warranty with ongoing support to ensure optimal performance.

About PT

With over 20 years of experience, PT is a trusted global supplier of cooling tower components. Our expertise ensures high-quality, reliable solutions for industries worldwide. Request a Quote to explore how we can meet your cooling needs.

Frequently Asked Questions (FAQ)

What is the function of Marley Drift Eliminators?

They capture water droplets to reduce drift, enhance efficiency, and conserve water.

What materials are used for the eliminators?

High-performance PVC or FRP with UV and corrosion resistance.

Can the eliminators be customized?

Yes, tailored solutions are available for specific tower requirements.

What is the lifespan of the eliminators?

Typically exceeds 5–10 years with proper maintenance.

What industries use these eliminators?

Power generation, chemical processing, HVAC, and more.

How do the eliminators improve efficiency?

Low drift and airflow resistance enhance cooling and reduce energy use.

What is the delivery time for the eliminators?

Orders are delivered within 10 days.

Why Choose PT for Marley Drift Eliminators?

Premium Quality: Made with imported raw materials for durability.

Competitive Pricing: Flexible pricing tailored to market demands.

Expertise: Over 20 years of experience in cooling tower solutions.

Superior Service: Comprehensive support with a 12-month warranty.