Aluminium Alloy Impeller Fan for Cooling Tower Overview

The LF and LFL series Aluminium Alloy Impeller Fans are engineered for diverse cooling tower applications, offering high efficiency, low noise, and robust durability. Featuring advanced aerodynamic designs and high-quality materials, these fans ensure optimal airflow, minimal vibration, and long-term reliability. With customizable blade angles and multiple installation options, they meet a wide range of industrial cooling requirements.

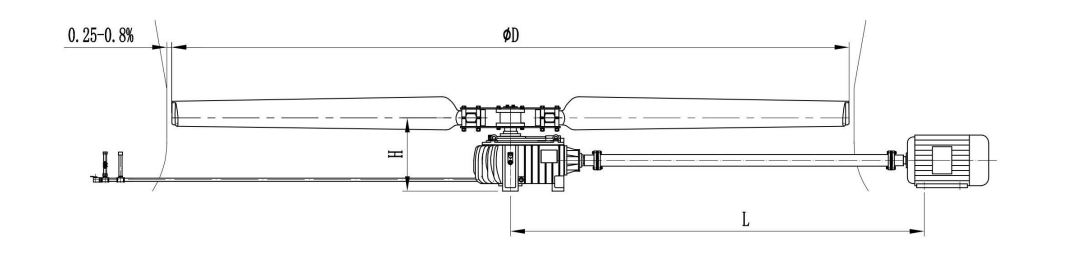

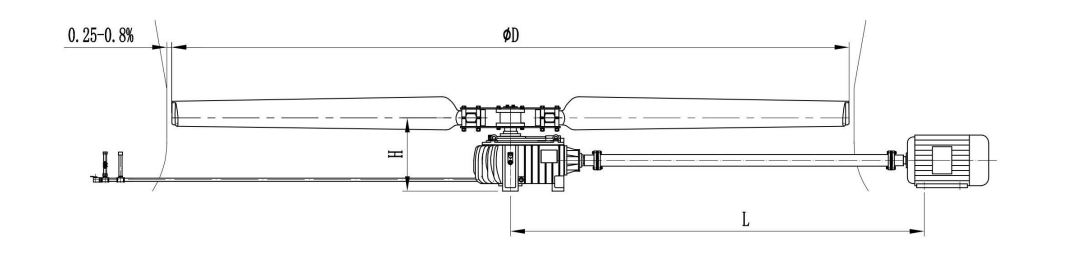

Aluminium Alloy Impeller Fan Specifications

The LF and LFL series fans are available in various models to suit different cooling tower configurations. Detailed parameters are provided on the fan nameplate, with additional technical details in the impeller and gearbox service manual.

| Fan Type | Gearbox Type | Impeller Type | Impeller Speed (RPM) | Blade Count | Total Pressure (Pa) | Air Volume (×10⁴ m³/h) | Power (kW) | Weight (kg) | D (mm) | L (mm) | H (mm) |

| LF30D | XLJ25 | XF30D | 269 | 4~6 | 110 | 22 | 11 | 270 | 3000 | 2200 | 590 |

| LFL30 | XLJ25 | XLF30 | 269 | 4~6 | 110 | 22 | 11 | 270 | 3000 | 2200 | 550 |

| LF34D | XLJ25 | XF34D | 269 | 4~6 | 120 | 31 | 15 | 290 | 3400 | 2400 | 590 |

| LFL34 | XLJ25 | XLF34 | 269 | 4~6 | 120 | 31 | 15 | 290 | 3400 | 2400 | 550 |

| LF36D | XLJ25 | XF36D | 240 | 4~6 | 130 | 31 | 15 | 310 | 3600 | 2500 | 590 |

| LFL36 | XLJ25 | XLF36 | 240 | 4~6 | 130 | 31 | 15 | 310 | 3600 | 2500 | 550 |

| LF38D | XLJ25 | XF38D | 240 | 4~6 | 130 | 31 | 15 | 330 | 3800 | 2600 | 590 |

| LFL38 | XLJ25 | XLF38 | 240 | 4~6 | 130 | 31 | 15 | 330 | 3800 | 2600 | 554 |

| LF40D | XLJ25 | XF40D | 226 | 4~6 | 140 | 36 | 22 | 390 | 4000 | 2750 | 590 |

| LFL40 | XLJ25 | XLF40 | 226 | 4~6 | 140 | 36 | 22 | 390 | 4000 | 2750 | 554 |

| LF42D | XLJ35 | XF42D | 248 | 4~6 | 170 | 47 | 30 | 420 | 4200 | 2900 | 685 |

| LFL42 | XLJ35 | XLF421 | 248 | 4~6 | 170 | 47 | 30 | 420 | 4200 | 2900 | 652 |

| LF45D | XLJ35 | XF45D | 223 | 4~6 | 170 | 58 | 37 | 450 | 4500 | 3000 | 685 |

| LFL45 | XLJ35 | XLF45 | 223 | 4~6 | 170 | 58 | 37 | 450 | 4500 | 3000 | 652 |

| LF45D | XLJ35 | XF45D | 248 | 4~6 | 200 | 60 | 45 | 450 | 4500 | 3000 | 685 |

| LFL45 | XLJ35 | XLF45 | 248 | 4~6 | 200 | 60 | 45 | 450 | 4500 | 3000 | 652 |

| LF47D | XLJ35 | XF47D | 200 | 4~6 | 160 | 59 | 37 | 470 | 4700 | 3050 | 685 |

| LFL47 | XLJ35 | XLF47 | 200 | 4~6 | 160 | 59 | 37 | 470 | 4700 | 3050 | 652 |

| LF47D | XLJ35 | XF47D | 223 | 4~6 | 190 | 64 | 45 | 520 | 4700 | 3050 | 685 |

| LFL47 | XLJ35 | XLF47 | 223 | 4~6 | 190 | 64 | 45 | 520 | 4700 | 3050 | 652 |

| LF50D | XLJ35 | XF50D | 200 | 4~6 | 160 | 59 | 37 | 480 | 5000 | 3200 | 685 |

| LFL50 | XLJ35 | XLF50 | 200 | 4~6 | 160 | 59 | 37 | 480 | 5000 | 3200 | 652 |

| LF50D | XLJ35 | XF50D | 223 | 4~6 | 180 | 67 | 45 | 530 | 5000 | 3200 | 685 |

| LFL50 | XLJ35 | XLF50 | 223 | 4~6 | 180 | 67 | 45 | 530 | 5000 | 3200 | 652 |

| LF55D | XLJ45 | XF55D | 183 | 5~6 | 170 | 86 | 55 | 760 | 5500 | 3500 | 826 |

| LF60D | XLJ45 | XF60D | 166 | 5~6 | 160 | 92 | 55 | 780 | 6000 | 3700 | 826 |

| LF60D | XLJ50 | XF60D | 187 | 6~7 | 180 | 105 | 75 | 1020 | 6000 | 3700 | 880 |

| LF67D | XLJ50 | XF67D | 155 | 5~6 | 190 | 136 | 90 | 1260 | 6706 | 4150 | 880 |

| LF70D | XLJ50 | XF70D | 155 | 5~6 | 180 | 141 | 90 | 1340 | 7000 | 4300 | 880 |

| LF73D | XLJ50 | XF73D | 155 | 5~6 | 170 | 145 | 90 | 1380 | 7315 | 4400 | 880 |

| LF77D | XLJ50 | XF77D | 140 | 5~6 | 160 | 150 | 90 | 1420 | 7700 | 4650 | 888 |

| LF80D | XLJ50 | XF80D | 140 | 5~7 | 160 | 150 | 90 | 1490 | 8000 | 4800 | 888 |

| LF80D | XLJ55 | XF80D | 140 | 5~7 | 190 | 188 | 132 | 1650 | 8000 | 4800 | 928 |

| LF80D | XLJ60 | XF80D | 134 | 5~7 | 210 | 201 | 160 | 1870 | 8000 | 4800 | 998 |

| LF85D | XLJ60 | XF85D | 134 | 5~7 | 190 | 216 | 160 | 1930 | 8534 | 5000 | 998 |

Material Options

High-strength FRP or aluminium alloy for blades, ensuring durability and corrosion resistance.

Installation Options

Multiple configurations with adjustable blade angles for versatile installation.

Key Features of Aluminium Alloy Impeller Fan

High Strength and Durability

Composite Construction: FRP or aluminium alloy blades resist mechanical stress and impact.

Long Service Life: Withstands UV radiation, moisture, and chemicals for extended durability.

Lightweight Design

Corrosion Resistance

Aerodynamic Efficiency

Customizable and Adaptable

Low Maintenance

Environmental Compatibility

Safety and Reliability

Gearbox Performance

High Precision: Hard tooth surface gears ensure stable transmission.

Compact and Lightweight: Small volume with high bearing capacity.

Low Noise and Vibration: Enhances operational comfort and longevity.

Applications of Aluminium Alloy Impeller Fan

Used in industries including:

Industrial Process Cooling: Power generation, chemical, and petrochemical plants.

HVAC Systems: Large-scale air conditioning in commercial buildings.

Power Plants: Maintains optimal temperatures for turbines.

Water Treatment Plants: Supports cooling in water recycling processes.

Packaging and Shipping

Packaging

Packaged in sturdy wooden crates, cartons, or customized packaging to ensure safe transport and delivery.

Delivery Time

Shipped within 15 days.

Selling Units

Available as single units to accommodate specific project needs.

Our Services for Aluminium Alloy Impeller Fan

Pre-Sale Services

We provide product images, videos, quotations, and engineering drawings tailored to your needs. Factory visits are welcome.

Sale Services

Production schedule updates with photos.

24/7 support via phone, email, or online services.

On-site installation guidance and training available.

After-Sale Services

12-month warranty with ongoing support to ensure optimal performance.

About PT

With over 20 years of experience, PT is a trusted global supplier of cooling tower components. Our expertise ensures high-quality, reliable solutions for industries worldwide. Request a Quote to explore how we can meet your cooling needs.

Frequently Asked Questions (FAQ)

What is the purpose of the Aluminium Alloy Impeller Fan?

It enhances airflow in cooling towers to improve heat dissipation efficiency.

What materials are used for the fan blades?

High-strength FRP or aluminium alloy for durability and corrosion resistance.

Can the fan blades be customized?

Yes, blade sizes, angles, and configurations can be tailored to specific needs.

What is the typical lifespan of the fan?

Long-lasting with proper maintenance, typically exceeding 10 years.

What industries use these fans?

Power generation, chemical processing, HVAC, and water treatment.

How do these fans improve cooling efficiency?

Optimized airfoil design and low resistance enhance airflow and reduce energy consumption.

What is the delivery time for the fans?

Orders are delivered within 15 days.

Why Choose PT for Aluminium Alloy Impeller Fan?

Premium Quality: Made with imported raw materials for durability.

Competitive Pricing: Flexible pricing tailored to market demands.

Expertise: Over 20 years of experience in cooling tower solutions.

Superior Service: Comprehensive support with a 12-month warranty.