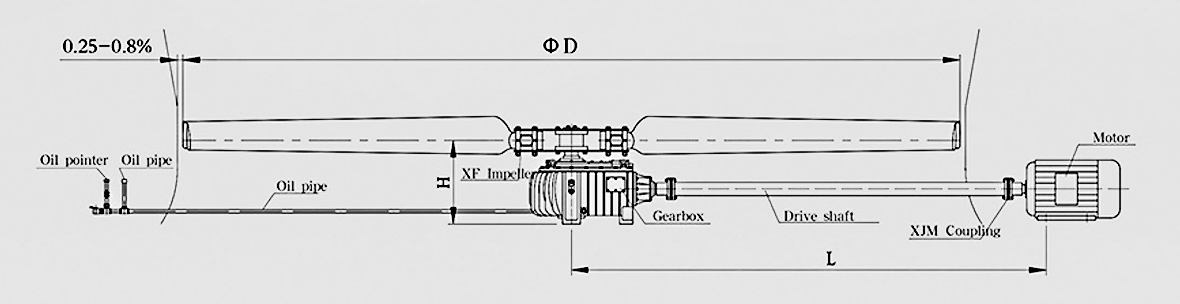

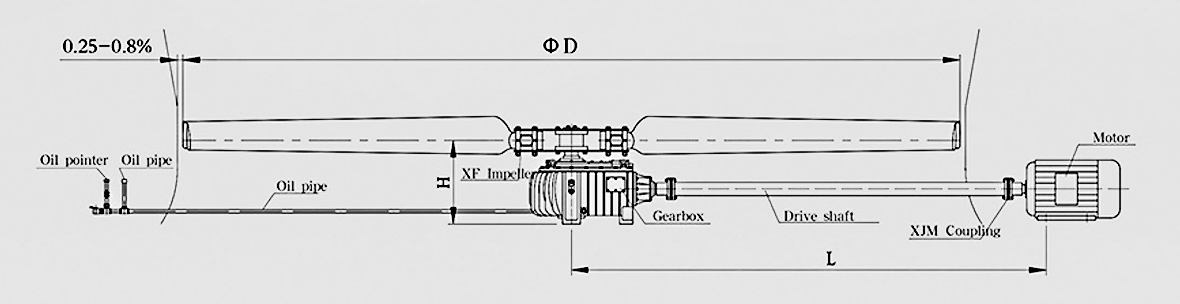

XDZ shaft and XDZt sahft are designed for cooling tower fans. They have compact structure and high manufacturing accurecy, which make them working smoothly and low vibration. The drive shaft of a cooling tower is a crucial component in the cooling tower system. It is primarily responsible for transmitting the power generated by the motor to the cooling tower fan, ensuring that the fan can operate stably and efficiently. Through the connection of the drive shaft, the rotational motion of the motor is accurately conveyed to the fan blades, enabling the blades to rotate at the set speed and direction. This rotation generates sufficient airflow to dissipate the heat from the hot water inside the cooling tower into the atmosphere, achieving the cooling effect of the hot water. During this process, the drive shaft not only transmits power but also ensures the smoothness, reliability, and efficiency of power transmission through its structural design and material properties. It reduces energy loss and mechanical vibration, ensuring the normal operation of the entire cooling tower system and plays a vital role in maintaining the cooling efficiency and service life of the cooling tower.

Carbon Fiber Drive Shaft For Cooling Tower Parameter

Speed 1485rpm

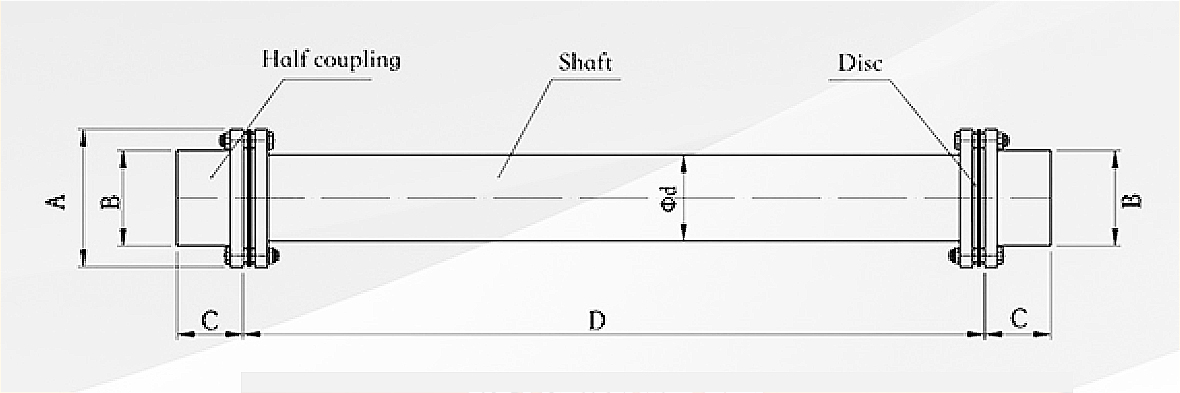

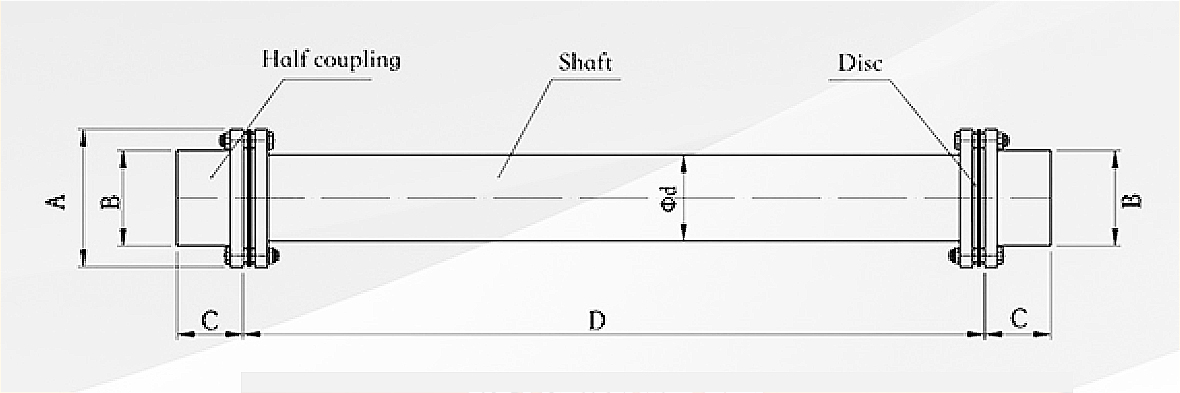

| Type | Material | Coupling

| Dmax | A | B | Cmax | D | Power(kw)

| Weight(KG) |

| XDZ70 | SS304 | XJM06 | 2400 | 143 | 84 | 90 | 76 | 22 | 32 |

| XDZ80 | SS304 | XJM06 | 2700 | 143 | 84 | 90 | 89 | 45 | 38 |

| XDZ100 | SS304 | XJM07 | 2900 | 169 | 100 | 90 | 108 | 55 | 52 |

| XDZ140 | SS304 | XJM08 | 3400 | 194 | 110 | 115 | 141 | 90 | 81 |

| XDZ160 | SS304 | XJM08 | 3800 | 194 | 110 | 115 | 168 | 160 | 98 |

| XDZ210 | SS304 | XJM10 | 4300 | 240 | 150 | 115 | 219 | 200 | 152 |

| XDZT70 | CFRP | XJM06 | 3100 | 143 | 84 | 90 | 77 | 45 | 21 |

| XDZT85 | CFRP | XJM07 | 3400 | 169 | 100 | 90 | 92 | 55 | 24 |

| XDZT100 | CFRP | XJM08 | 3700 | 194 | 110 | 115 | 108 | 90 | 33 |

| XDZT120 | CFRP | XJM08 | 4100 | 194 | 110 | 115 | 128 | 160 | 36 |

| XDZT150 | CFRP | XJM10 | 4600 | 240 | 150 | 115 | 158 | 220 | 45 |

| XDZT180 | CFRP | XJM10 | 4900 | 240 | 150 | 115 | 188 | 250 | 66 |

| XDZT200 | CFRP | XJM10 | 5300 | 240 | 150 | 115 | 208 | 315 | 87 |

Features of Carbon Fiber Drive Shaft For Cooling Tower

1. Carbon Fiber Drive Shaft For Cooling Tower Material Properties

-

Carbon Fiber Drive Shaft:

Carbon fiber drive shafts are characterized by their high strength, lightweight, corrosion resistance, and low vibration. Carbon fiber has a tensile strength 6 to 12 times that of ordinary steel, with a higher elastic modulus, excellent creep resistance, and corrosion resistance. Its weight is only 1/5 that of steel, making it highly resilient, low in noise, easy to install, and ensuring high-quality construction. The lightweight design also contributes to energy savings during fan operation. -

Stainless Steel Drive Shaft:

Stainless steel drive shafts offer good corrosion resistance, making them suitable for damp and corrosive environments. They also have high strength and rigidity, though they are heavier, which may increase motor energy consumption. -

Composite Drive Shaft:

Composite drive shafts (such as those made from carbon fiber and glass fiber) feature lightweight, high strength, corrosion resistance, low noise, and low thermal expansion. Compared to traditional metal drive shafts, they can reduce weight by 40% to 70%, improve transmission efficiency, have a longer service life, and achieve energy savings of over 30%.

2.Carbon Fiber Drive Shaft For Cooling Tower Structural Features

-

Carbon Fiber Drive Shaft For Cooling Tower Modular Structure:

Some cooling tower drive shafts adopt a modular structure for easy installation and maintenance. For example, carbon fiber drive shafts with modular designs can be connected through flanges and bolts, simplifying the installation process. -

Carbon Fiber Drive Shaft For Cooling Tower Elastic Couplings:

Drive shafts are often equipped with elastic couplings (such as diaphragm couplings) that can compensate for axial, radial, and angular deviations, reducing vibration and noise, and enhancing the stability and reliability of the transmission system. -

Carbon Fiber Drive Shaft For Cooling Tower Reinforced Connection Structure:

To enhance the stability and strength of the drive shaft, some designs use reinforced connection structures, such as composite material pins to fix flanges and tube bodies.

3. Carbon Fiber Drive Shaft For Cooling Tower Dynamic Features

-

Carbon Fiber Drive Shaft For Cooling Tower High-Speed Operation:

Carbon fiber drive shafts have a critical speed as high as 3000rpm, significantly higher than the synchronous speed of the motor. This effectively reduces fan vibration and ensures safer operation. -

Carbon Fiber Drive Shaft For Cooling Tower Low Vibration:

With elastic couplings and high-precision dynamic balancing, drive shafts exhibit low vibration during operation, improving the stability and service life of the entire cooling tower system.

How to Choose the Right Carbon Fiber Drive Shaft For Cooling Tower

Carbon Fiber Drive Shaft For Cooling Tower Material Selection

-

Carbon Fiber Drive Shaft For Cooling Tower Environmental Adaptability:

If the cooling tower is located in a damp or corrosive environment, it is recommended to choose carbon fiber or composite drive shafts, which offer excellent corrosion resistance. -

Carbon Fiber Drive Shaft For Cooling Tower Weight and Energy Efficiency:

Carbon fiber drive shafts are lightweight and can reduce motor energy consumption, making them suitable for applications with high energy-saving requirements. -

Carbon Fiber Drive Shaft For Cooling Tower Strength and Rigidity:

For applications requiring high torque transmission and rigidity, carbon fiber and composite drive shafts are good choices.

2. Carbon Fiber Drive Shaft For Cooling Tower Structural Design

-

Carbon Fiber Drive Shaft For Cooling Tower Installation and Maintenance:

Modular drive shafts are easy to install and maintain, making them suitable for cooling tower systems that require frequent inspections. -

Carbon Fiber Drive Shaft For Cooling Tower Compensation Capability:

Elastic couplings can compensate for axial, radial, and angular deviations, making them suitable for applications with high installation precision requirements. -

Carbon Fiber Drive Shaft For Cooling Tower Reinforced Connections:

For large-span or high-load cooling towers, drive shafts with reinforced connection structures can improve the stability and reliability of the system.

3. Carbon Fiber Drive Shaft For Cooling Tower Dynamic Performance

-

Carbon Fiber Drive Shaft For Cooling Tower Speed Matching:

Ensure that the critical speed of the drive shaft is higher than the synchronous speed of the motor to avoid resonance and reduce vibration. -

Carbon Fiber Drive Shaft For Cooling Tower Dynamic Balancing:

Choose drive shafts that have undergone strict dynamic balancing to reduce vibration and noise during operation.

4. Carbon Fiber Drive Shaft For Cooling Tower Cost and Cost-effectiveness

-

Carbon Fiber Drive Shaft For Cooling Tower Initial Investment:

Carbon fiber and composite drive shafts have a higher initial investment, but their long service life and low maintenance costs make them cost-effective in the long run. -

Carbon Fiber Drive Shaft For Cooling Tower Energy-saving Effects:

Carbon fiber drive shafts are lightweight and can reduce motor energy consumption. For cooling tower systems with long operating hours and high energy consumption, the energy-saving effects are significant.

Conclusion Of Carbon Fiber Drive Shaft For Cooling Tower

Choosing the right drive shaft for a cooling tower requires a comprehensive consideration of material properties, structural design, dynamic performance, and cost-effectiveness. Carbon fiber and composite drive shafts are increasingly becoming the preferred materials for cooling tower drive shafts due to their lightweight, high strength, corrosion resistance, and low vibration. Meanwhile, rational structural design and dynamic optimization can further improve the performance and reliability of the drive shaft. When selecting, it is essential to weigh different factors based on the specific conditions and requirements of the cooling tower to choose the most suitable drive shaft.

Carbon Fiber Drive Shaft For Cooling Tower Shipment

Packing:

Wooden,cartons,custom package.

Delivery time:

With in 15 days.

Selling units:

Single item.

Our Services Of Carbon Fiber Drive Shaft For Cooling Tower

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.