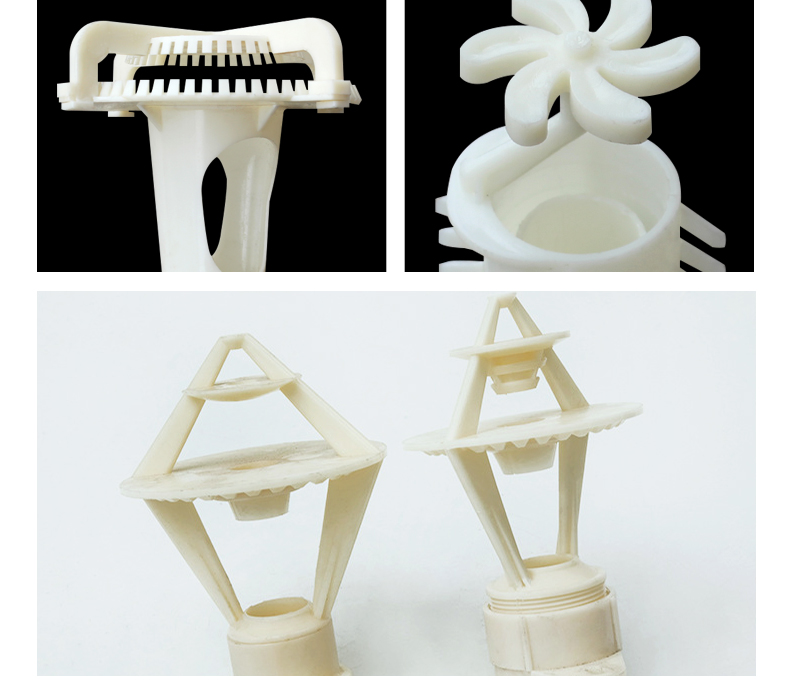

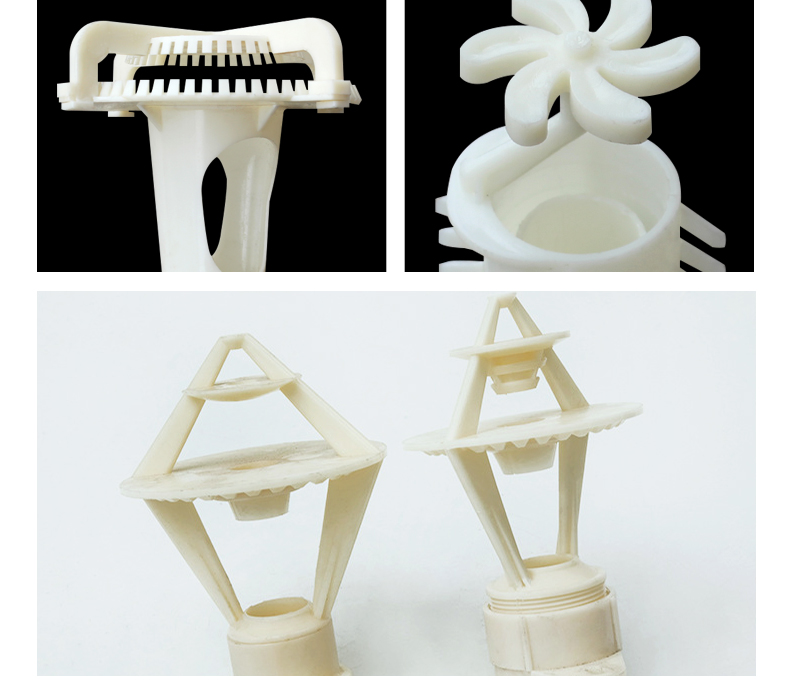

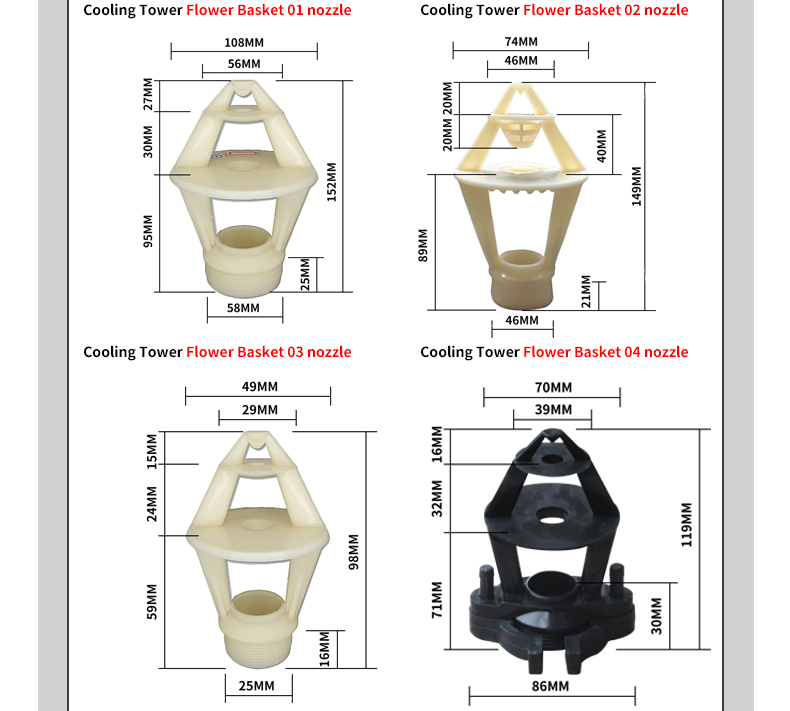

Triple Splash ABS Cooling Tower Nozzle Overview

The Triple Splash ABS Cooling Tower Nozzle is a high-efficiency water distribution component designed for cooling towers. Crafted from durable ABS plastic through one-time injection molding, it ensures uniform water distribution, low-pressure operation, and resistance to clogging. With a robust locking mechanism and a service life of up to 20 years, it guarantees long-term reliability in various industrial cooling systems.

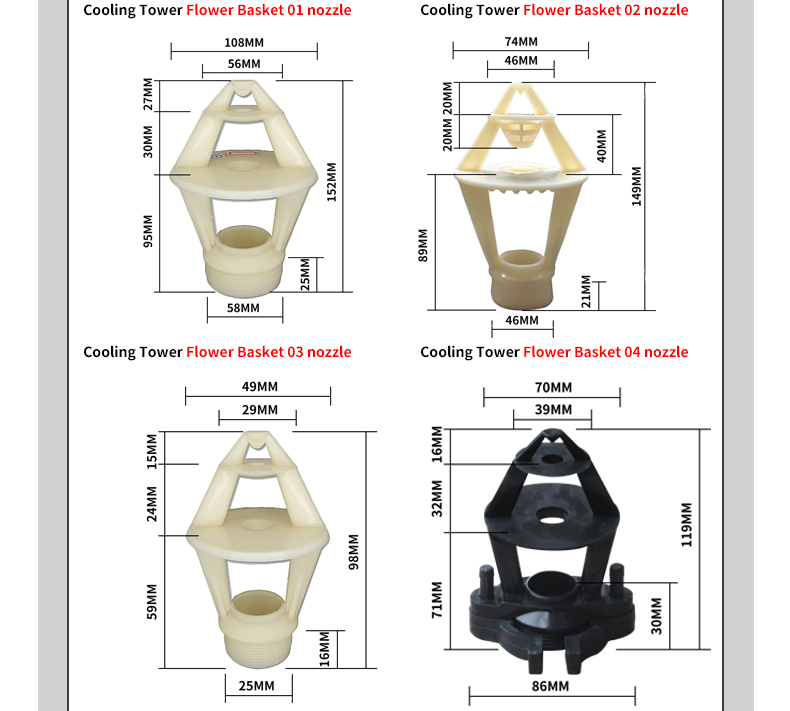

Triple Splash ABS Cooling Tower Nozzle Specifications

Key Features of Triple Splash ABS Cooling Tower Nozzle

Uniform Water Distribution: Ensures even water density across the cooling tower packing, eliminating dry spots.

Low-Pressure Operation: Operates effectively at 0.15 MPa (0.6m water head), reducing pump energy consumption.

Anti-Clogging Design: Large orifice design prevents blockages, even in poor water quality conditions.

High Strength and Durability: Injection-molded ABS or modified PP offers up to 20 years of service life.

Unique Structural Design: Combines columnar and swirl flows for optimal spray performance, with a locking anti-loosening device for secure connection.

Strong Adaptability: Maintains performance under varying hydraulic loads and flow rates.

Easy Installation and Maintenance: Flange or thread connection simplifies setup and upkeep.

Excellent Cooling Performance: Atomizes water for enhanced heat exchange in industrial systems.

Wide Application Range: Suitable for counterflow, crossflow, and fill-less cooling towers.

When to Replace Triple Splash ABS Cooling Tower Nozzle

Regular inspection is key to maintaining cooling efficiency. Replace nozzles under the following conditions:

Clogging

Cause: Impurities, scale, or microorganisms clog spray holes.

Symptoms: Reduced water volume and uneven distribution.

Solution: Replace if cleaning fails to restore performance.

Wear or Damage

Cause: Long-term water flow impact or corrosion.

Symptoms: Altered spray shape or water flow.

Solution: Replace worn or damaged nozzles promptly.

Aging

Cause: Prolonged exposure to high temperatures and humidity.

Symptoms: Reduced water flow or altered spray angles.

Solution: Replace based on service life and operating conditions.

Uneven Water Distribution

Cause: Blockage, damage, or pipe deformation.

Symptoms: Dry spots on packing, reduced heat exchange efficiency.

Solution: Clean or replace nozzles and inspect pipes for issues.

Reduced Cooling Efficiency

Cause: Poor water flow or spray performance.

Symptoms: High water temperatures, decreased system efficiency.

Solution: Replace problematic nozzles.

Unsuitable Material for Water Quality

Cause: Corrosive substances in water damage nozzles.

Symptoms: Cracks, holes, or deformation.

Solution: Use corrosion-resistant materials like stainless steel or enhanced plastics.

Applications of Triple Splash ABS Cooling Tower Nozzle

The Triple Splash ABS Cooling Tower Nozzle is used in industries including:

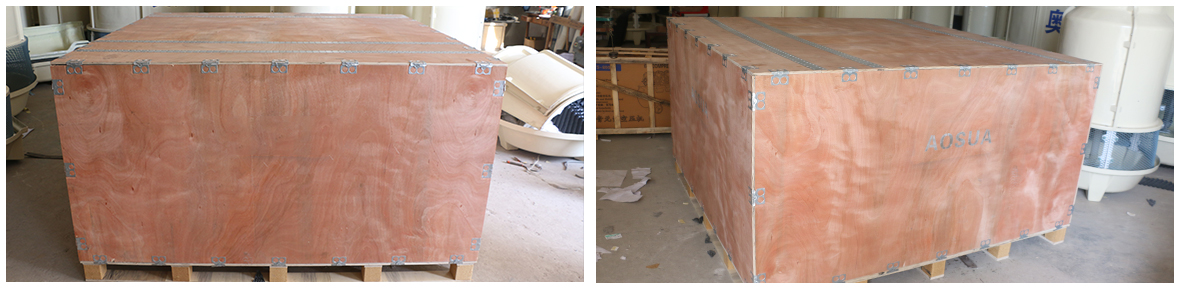

Packaging and Shipping

Packaging

Packaged on wooden pallets.

Delivery Time

Shipped within 10 days.

Our Services for Triple Splash ABS Cooling Tower Nozzle

Pre-Sale Services

We provide product images, videos, quotations, and engineering drawings tailored to your needs. Factory visits are welcome.

Sale Services

Production schedule updates with photos.

24/7 support via phone, email, or online services.

On-site installation guidance and training available.

After-Sale Services

12-month warranty with ongoing support to ensure optimal performance.

About PT

With over 20 years of experience, PT is a trusted global supplier of cooling tower components. Our expertise ensures high-quality, reliable solutions for industries worldwide. Request a Quote to explore how we can meet your cooling needs.

Frequently Asked Questions (FAQ)

What is the purpose of the Triple Splash ABS Cooling Tower Nozzle?

It distributes water evenly to enhance cooling efficiency in cooling towers.

What material is the nozzle made from?

ABS plastic or modified PP for durability and corrosion resistance.

What is the lifespan of the nozzle?

Up to 20 years under normal operating conditions.

When should the nozzle be replaced?

Replace if clogged, worn, aged, or causing uneven water distribution.

How does the nozzle prevent clogging?

Large orifice design avoids blockages from impurities.

What industries use this nozzle?

Power generation, chemical processing, HVAC, and more.

What is the delivery time for the nozzles?

Orders are delivered within 10 days.