Introduction to Cooling Tower Nozzles

The cooling tower nozzle is a key component in the cooling tower water distribution system. Its main function is to evenly spray circulating hot water onto the surface of the packing or heat exchange area, allowing the water to fully contact with the air, thereby improving the efficiency of evaporation and heat dissipation. The performance of the nozzle directly affects the cooling efficiency, energy consumption, water consumption, and operational stability of the cooling tower.

Cooling tower nozzles are widely used in industrial and commercial cooling systems in industries such as power, chemical, steel, petrochemical, HVAC, and HVAC.

Main characteristics of cooling tower nozzles

1. Uniform distribution of water

The high-quality cooling tower nozzle adopts scientific hydraulic design, which can form a stable and uniform spray water type (such as full cone, hemispherical or multi-directional spray), ensuring that there is no dry area on the packing surface, thereby improving the overall heat transfer efficiency.

2. Not easily clogged

Most cooling tower nozzles adopt a large channel structure without complex flow guides inside, which can effectively pass impurities, suspended solids, and scaling particles in water, especially suitable for poor water quality or circulating water systems.

3. Corrosion resistance and long service life

The nozzle is usually made of PP (polypropylene), ABS, PVC or engineering plastics, and stainless steel material can also be selected for some working conditions. It has good corrosion resistance, chemical resistance and aging resistance, and is suitable for long-term continuous operation.

4. Low work pressure requirements

Most cooling tower nozzles are gravity or low-pressure nozzles, which can achieve good spraying effects under low water head conditions, helping to reduce system operating energy consumption and improve overall economy.

5. Easy installation and maintenance

Cooling tower nozzles are often connected using snap on, threaded, or plug-in connections, which are quick to disassemble and easy to inspect, clean, or replace regularly, reducing maintenance time and downtime costs.

6. Adapt to multiple types of cooling towers

It can be widely applied to cross flow cooling towers, counter flow cooling towers, circular cooling towers, and square cooling towers, and supports OEM matching and old tower renovation projects.

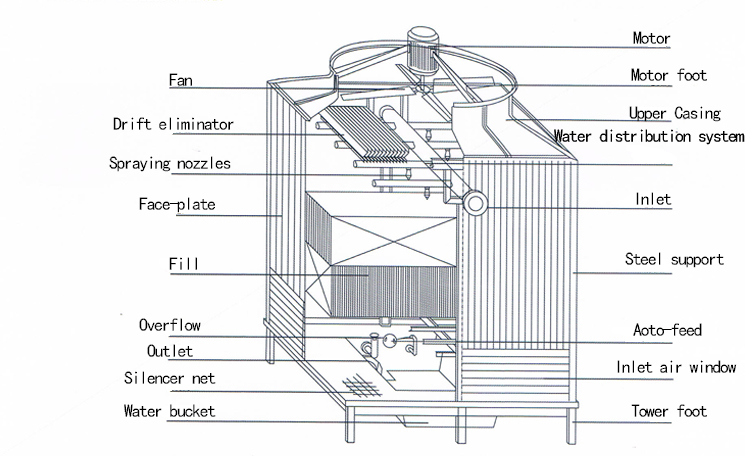

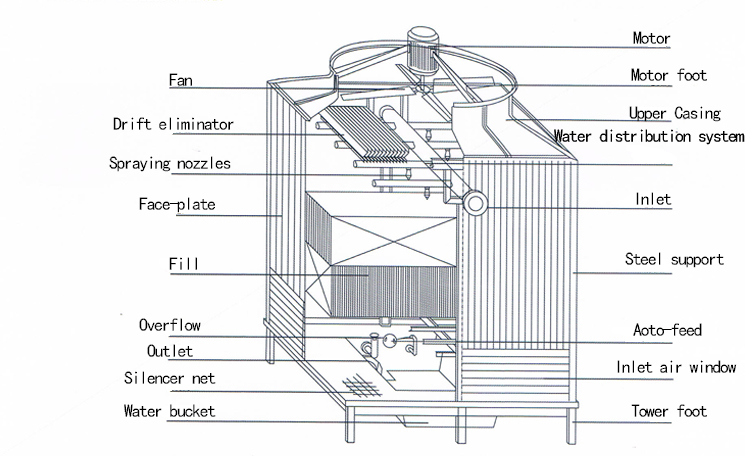

Schematic diagram of nozzle in cooling tower

Why are cooling tower nozzles so popular in the USA market

Cooling tower nozzles are popular in the US market mainly because the industrial and commercial sectors in the US rely heavily on the long-term and stable operation of cooling towers. As a key vulnerable component, nozzles have the advantages of low replacement cost, fast effectiveness, and easy maintenance; At the same time, the US market focuses on equipment maintenance and retrofit (Aftermarket&Retrofit), with a high degree of standardization. Nozzles can directly replace OEM products, significantly improving water distribution uniformity, cooling efficiency, and reducing energy and water consumption without replacing the entire tower. In addition, the high emphasis on energy conservation, environmental protection, and operational reliability has made cooling tower nozzles a mature market with stable demand and wide applications.

TOP 5 Cooling Tower Nozzle Manufacturers in USA

1. Power Tower Cooling Technology (Shaoxing) Co.,Ltd(China)

Overview:

PT is an excellent domestic manufacturer of cooling tower parts. Since its establishment in 2009, PT has always adhered to the concept of "long-lasting quality and endless innovation".PT Produce various types of three splash nozzles, Marley nozzles, sewage nozzles, flower basket nozzles, etc., made of ABS material. The company has over 40 product inventions practical technology patents, and has iS09001, 1S014000, and other certifications.PT cooling tower parts are exported worldwide, especially in Southeast Asia.

2. Baltimore Aircoil Company (BAC)

Overview:

Baltimore Aircoil Company (BAC) is a major US cooling tower system manufacturer that also supplies water distribution nozzles as part of its cooling tower parts portfolio. BAC’s nozzle offerings (such as the 360™ spray nozzle and XF gravity feed nozzles) provide effective spray coverage and are designed for easy inspection and maintenance. BAC parts are widely used in original equipment and retrofit applications across industrial and commercial cooling systems.

3. EVAPCO, Inc.

Overview:

EVAPCO is a US-based producer of cooling towers and auxiliary components, including nozzle and water distribution systems like the EvapJet™ nozzle design (used in many of its cooling tower products). EVAPCO’s nozzle systems are engineered to deliver uniform water distribution over fill and reduce clogging while enhancing thermal performance. Its solutions serve a wide range of industrial and HVAC cooling needs.

4. Brentwood Industries (Cooling Tower Nozzles & Components)

Overview:

Brentwood Industries manufactures a range of engineered cooling tower nozzles as part of its broader cooling tower components portfolio. Products include AccuSpray, DekSpray, SPN spray nozzles, and other spray distribution nozzles designed for uniform water coverage with strong clog resistance and long service life. Brentwood focuses on high-performance polymer nozzle designs optimized for varied cooling tower configurations.

5. Midwest Cooling Towers

Overview:

Midwest Cooling Towers is a US manufacturer and supplier of cooling tower parts and accessories, including a line of Precision-Flo water distribution nozzles and counterflow nozzles. These polypropylene nozzles are designed for robust corrosion resistance, uniform spray patterns, and ease of installation and cleaning, making them suitable for both OEM and retrofit cooling tower applications.