What is a cooling tower pump?

In modern building air conditioning systems and industrial cooling systems, cooling towers are very important cooling devices. One of the core devices that truly drives water flow and maintains stable system operation throughout the entire cooling cycle is the Cooling Tower Pump. It is responsible for continuously circulating water between the cooling tower and other equipment, thereby completing the transfer and dissipation of heat.

Definition of cooling tower pump

The cooling tower water pump is a mechanical equipment used to transport the heated circulating water to the cooling tower for cooling, and to re transport the cooled water back to the system.

It is usually dominated by centrifugal pumps, which have the characteristics of high flow rate and low head, ensuring the continuous and efficient circulation of water in the cooling system.

In short, the cooling tower water pump is the "power core" of the cooling circulation system.

Working principle of cooling tower water pump

The operation of the cooling tower water pump mainly includes the following steps:

1. Extract system return water

Pumps extract high temperature water from condensers, heat exchangers, or process equipment.

2. Transport hot water to the top of the cooling tower

Hot water is evenly distributed on the packing material through a spray device and evaporates and dissipates heat when in contact with air.

3. Reflux after cooling

The cooled water flows to the bottom of the cooling tower and is then pumped back to the system to continue absorbing heat.

This cycle repeats continuously to maintain the entire cooling system in a stable temperature state.

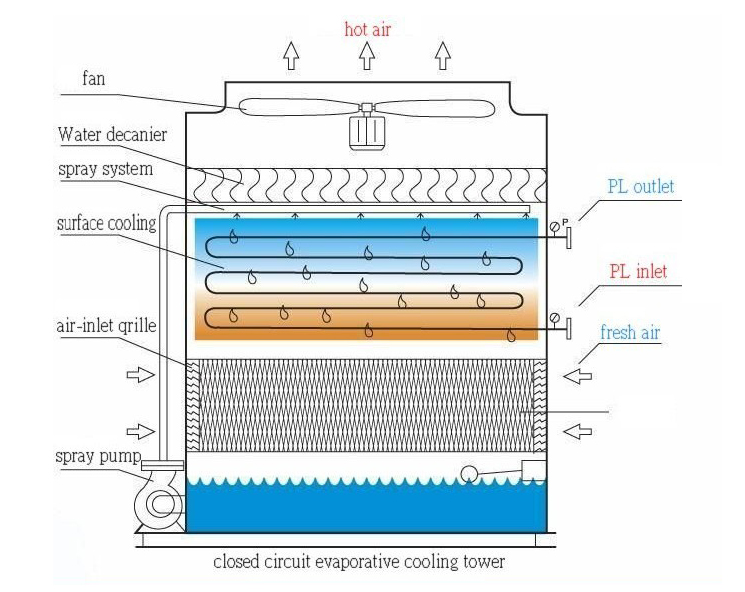

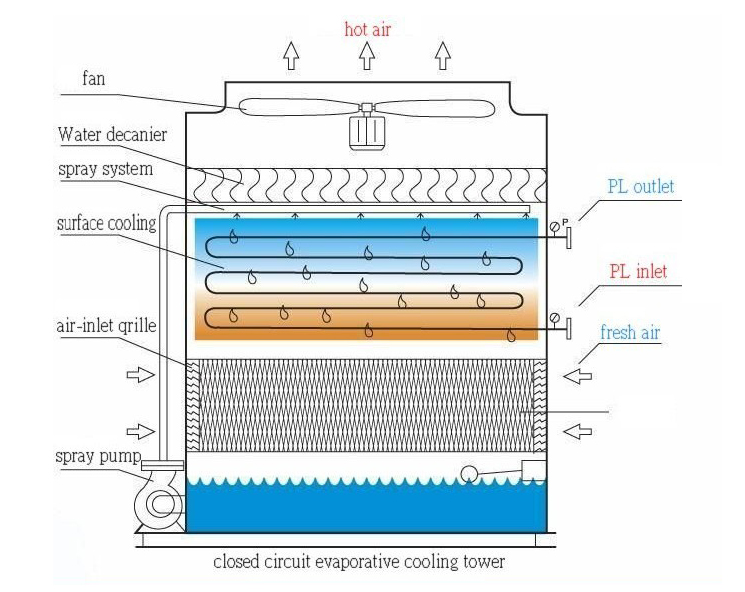

Schematic diagram of pump in cooling tower

Advantages of cooling tower pump

1. Materials and Corrosion Resistance

The pump body is often made of cast iron or stainless steel, and stainless steel material can cope with complex water quality or corrosive media, extending equipment life

2. Can ensure stable and reliable cooling cycle

The cooling tower water pump provides continuous water flow power, allowing the hot water inside the system to be smoothly transported to the cooling tower for heat dissipation, and is the core equipment of the cooling cycle. It has high stability and can operate continuously for 24 hours.

3. High traffic and energy efficiency

Cooling tower systems typically require hydraulic characteristics of "high flow, low head", and cooling tower water pumps are designed for this purpose. Centrifugal structure can provide a large amount of water circulation at low energy consumption, ensuring efficient heat transfer of the system.

4.Widely applicable scenarios

Suitable for industrial cooling, air conditioning systems, food processing and other fields, able to adapt to flow fluctuations and seasonal water volume changes

Maintenance suggestions for cooling tower pumps

Daily maintenance (daily/shift)

1. Running inspection

1)Observe whether the running sound of the pump is stable, whether there is friction, abnormal noise, or cavitation sound.

2)Check the vibration condition, touch the pump body, and if the vibration is obvious, stop the machine for inspection.

3)Check if the outlet pressure and flow rate are normal.

4)Observe whether the motor current is within the rated range.

2. Appearance inspection

1)Check if there is any water leakage in the pump body, flange, and seal.

2)Observe whether the mechanical seal leaks normally (a very small amount of moisture is considered normal).

3. Temperature monitoring

1)The motor temperature should not exceed 80 ° C (refer to the actual nameplate).

2)The bearing temperature should not exceed 70 ° C.

Regular maintenance (monthly/quarterly)

1. Lubrication

1)Check whether the lubricating grease of the motor and pump bearings has deteriorated or is insufficient.

2)If lubricated with oil, check if the oil level in the oil window is normal.

2. Mechanical seal and shaft seal inspection

1)Observe for any abnormal dripping.

2)Check if the cooling water channel (if any) is unobstructed.

3. Inspection of connectors

1)Check if the foot bolts and coupling bolts are loose.

2)Check whether the rubber pad of the flexible coupling is aged or torn.

4. Electrical inspection

1)Measure the periodic insulation resistance.

2)Check if the motor wiring terminals are loose.

5. Pipelines and valves

1)Clean the filter (if there is a Y-shaped filter).

2)Check if the inlet valve and check valve are functioning properly.

Annual maintenance (or major overhaul)

1. Disassembly and internal inspection

1)Disassemble and inspect the impeller, check for wear and corrosion.

2)Check if the shaft sleeve is worn and replace it if necessary.

3)Check the straightness of the pump shaft and align the coupling.

4)Check the wear of the mechanical seal and replace the dynamic and static rings if necessary.

2. Cleaning

1)Clean the pump body, flow channel, scale and impurities.

2)Remove algae, sediment, and scale from the impeller.

3. Check the bearings

1)Replace the pump shaft bearings (usually recommended to replace once every 1-2 years, depending on the operating hours).

2)Check the motor bearings and add or replace lubricating grease.

4. Motor maintenance

1)Disassemble and inspect the fan and heat sink.

2)Perform dynamic balancing if necessary (if there is significant vibration).