What is Cooling Tower Motor

Cooling tower motor is a driving motor installed on the cooling tower, used to drive the cooling tower fan to rotate, thereby pushing air to flow through the cooling water, increasing the heat exchange efficiency between water and air, and achieving a decrease in water temperature.

Main applications:

Industrial cooling, water treatment systems, air conditioning cooling systems, power plants, etc.

Working environment:

It usually works in high humidity, high temperature, dusty or corrosive environments, so motors usually require waterproof, dustproof, and anti-corrosion design.

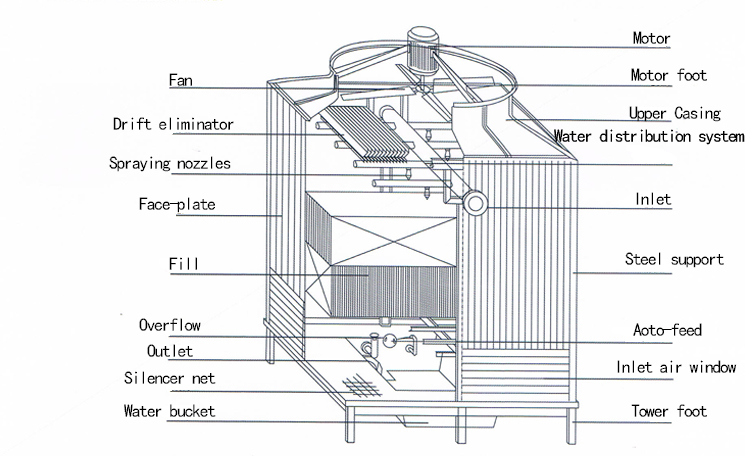

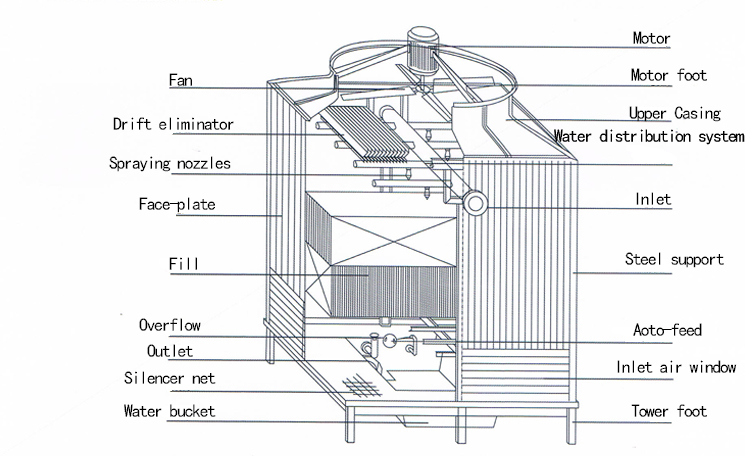

Composition

1)Motor body (AC or DC motor, mostly three-phase asynchronous motor)

2)Fan coupling or pulley

3)Control device (soft starter or frequency converter, used for speed regulation and protection)

1)High Efficiency and Energy Saving

Modern cooling tower motors often use high-efficiency and energy-saving motors (such as IE3 and IE4 levels) to reduce energy consumption and improve operational efficiency.

Cooperate with variable frequency drive (VFD) to adjust the fan speed according to the load demand, further saving energy.

2)durable and reliable

Suitable for high humidity and high corrosion environments, the protection level is generally IP55 or higher, and the motor winding is usually made of moisture-proof materials.

High mechanical strength, capable of withstanding the load impact of cooling tower fans.

3)Easy maintenance

Most of them are enclosed motors or air-cooled motors, which reduce the damage of dust and water vapor to the inside of the motor.

Compared with traditional motors, it has a longer maintenance cycle and is easier to repair.

4)Adaptable

Can be matched with different types of fans (axial flow, centrifugal fans).

It can achieve remote control and automated management, facilitating centralized control in industrial parks.

5)Runs smoothly

High quality bearings and precision machining ensure smooth operation, low noise, and minimal vibration.

Long term operation has high reliability and reduces the risk of downtime.

TOP 5 Cooling Tower Motor Manufacturers in South Korea

1. Power Tower Cooling Technology (Shaoxing) Co.,Ltd(China)

Company profile:

PT is an excellent domestic manufacturer of cooling tower parts. Since its establishment in 2009, PT has always adhered to the concept of "long-lasting quality and endless innovation".The company has over 40 product inventions practical technology patents, and has iS09001, 1S014000, and other certifications.PT produces various cooling tower motors: three-phase asynchronous motors, gear reduction motors (with gearbox), waterproof and explosion-proof motors, variable frequency motors, etc., as well as various brands of motors: TECO, Liangchi Motor, WEG Motor, Siemens Motor, etc.PT cooling tower parts are exported worldwide, especially in Southeast Asia.

2. LS Electric

Company profile:

LS Electric is a leading South Korean electrical equipment and motor manufacturer with over 40 years of experience in producing AC induction motors, DC motors, and energy‑efficient solutions across HVAC, pump, and fan applications. The company’s motors are designed for high efficiency, low vibration and sound, and long service life—traits that can benefit cooling tower motor applications requiring continuous and stable operation.

3. Doosan Heavy Industries & Construction

Company profile:

Doosan Heavy Industries & Construction has a long history in supplying large‑scale industrial equipment, including electric motors for power plants, industrial facilities, and heavy machinery. Known for durable, high‑reliability motor and drive systems, Doosan products are engineered for harsh operating conditions, making them suitable for cooling tower installations in sectors such as power, petrochemical, and manufacturing.

4. Jungwoo Motor

Company profile:

Jungwoo Motor is a South Korean industrial motor specialist that produces a range of three‑phase motors, single‑phase motors, inverter‑compatible motors, and brake/ordering motors for various industrial applications. With decades of focus on quality and customer satisfaction, Jungwoo’s motors offer adaptability and performance needed for industrial cooling tower fans and related drive systems.

5. Higen Motor Co., Ltd.

Company profile:

Higen Motor is a Korean motor manufacturer offering a variety of induction motors, vector inverter motors, totally enclosed fan‑cooled designs, and high‑voltage motors, which can be applied in industrial settings. Their motor portfolio supports different power and control requirements, making them suitable for cooling tower motor applications that demand robust performance and compliance with industrial standards.