Here’s a clear, practical guide on cooling tower nozzle replacement — what to check, how to choose the right replacement, and the steps to change them safely.

✅ Cooling Tower Nozzle Replacement Guide

1. When Should Nozzles Be Replaced?

Replace spray/distribution nozzles if you notice:

* Uneven water distribution on fill

* Reduced thermal performance

* Clogged or partially blocked orifices

* Cracked ABS/PP/nylon material

* Missing splash cones or diffusers

* Excessive scale buildup that can’t be cleaned

✅ 2. Types of Cooling Tower Nozzles

Before replacing, confirm the type used in your tower:

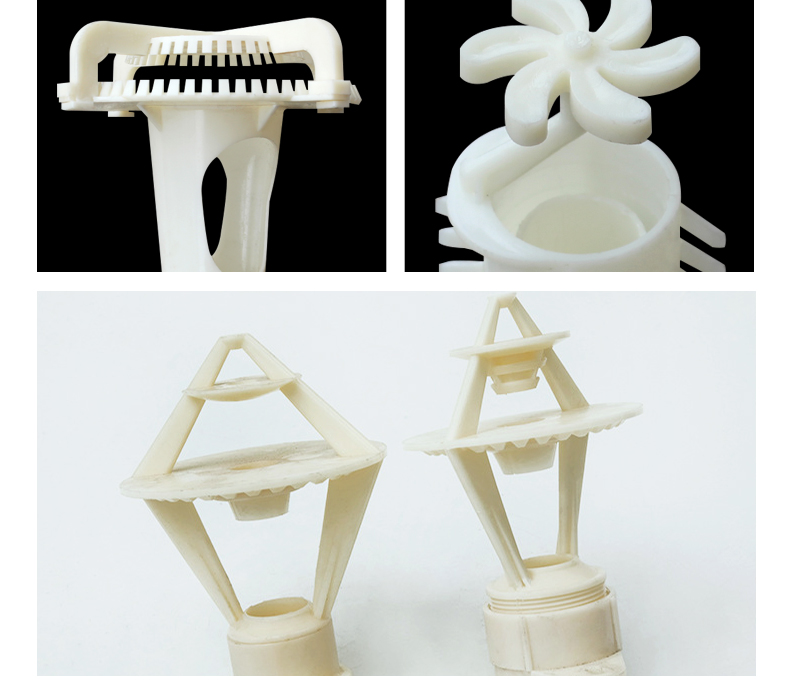

A. Splash / Spiral Nozzles

* ABS or PP material

* Common in Marley, BAC, Evapco towers

* Install by threading, snapping, or hanging

B. Target / Orifice Nozzles

* Used in pressurized systems

* Brass, ABS, or PP

* Designed for consistent droplet distribution

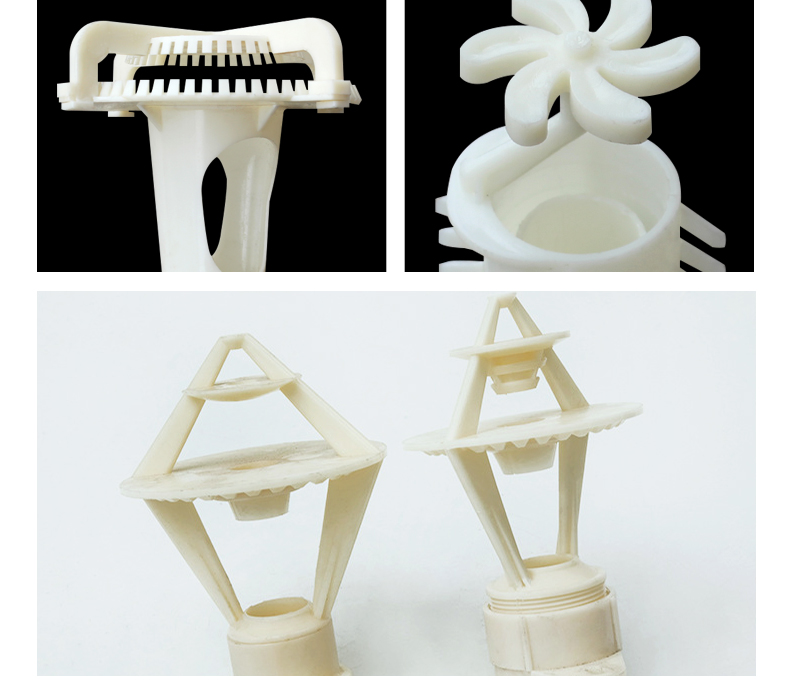

C. Full-cone or Hollow-cone Spray Nozzles

* Used in pressurized towers

* Available in multiple orifice sizes for precise flow control

✅ 3. How to Select the Correct Replacement Nozzle

Match the following specifications:

✔ Mounting Type

* **Threaded (½”, ¾”, 1”)**

* **Snap-in**

* **PVC pipe end–mounted**

* **Bayonet-type / clip-on**

✔ Flow Rate & Pressure

* Usually 2–10 psi in gravity systems

* 10–25 psi in pressurized systems

* Nozzle DPM (drops per minute) and GPM rating must match OEM

✔ Spray Pattern

* Full-cone is most common

* Angle typically 90°–120°

✔ Material

* ABS (most common)

* PP (chemical resistant)

* Nylon (high temp)

* Brass / stainless steel (industrial, high-pressure)

If you tell me your tower brand (Marley, BAC, Evapco, Liang Chi, etc.), I can identify the exact nozzle type.

✅ 4. Step-by-Step Replacement Procedure

Step 1 – Shut Down & Lockout

* Turn off fan and pump

* Isolate water supply

Step 2 – Access Hot Water Basin or Header

* Remove basin covers

* Drain or lower water to safe level

Step 3 – Remove Old Nozzles

* Unthread by hand or with pliers

* Snap-in types: twist and pull

* Clip-on types: release retaining clips

Step 4 – Inspect Distribution Pipes / Basin

* Check for cracks, blockage

* Clean debris, algae, scale

Step 5 – Install New Nozzles

* Ensure proper orientation

* Do not overtighten plastic nozzles

* For snap-in types, confirm a tight seat

Step 6 – Check Orifice Size

* Verify consistency across the basin

* Replace all nozzles in a cell (best practice)

Step 7 – Restart the Pump

* Observe water distribution

* Look for:

* Dead spots on fill

* Overspray/underspray

* Leaks or misalignment

✅ 5. Recommended OEM & Aftermarket Nozzle Sources

If you need a list of manufacturers, here are common options:

* Marley / SPX – Spiral Target Nozzles

* BAC – Steel and plastic nozzles

* Evapco – ABS orifice nozzles

* Longhua / Liang Chi – Hanging ABS nozzles

* Delta – Polyethylene nozzles