Aluminum Cooling Tower Sprinkler Head: It is a water distribution device used for small and medium-sized round counter flow cooling towers. It is a key component in the cooling tower. Its function is to evenly distribute water onto the packing, widen the water vapor contact interface, vaporize a portion of the water, take away heat, and lower the water temperature. The shell is made of ABS and aluminum alloy, and the central component is divided into two types: ordinary bearings and stainless steel bearings

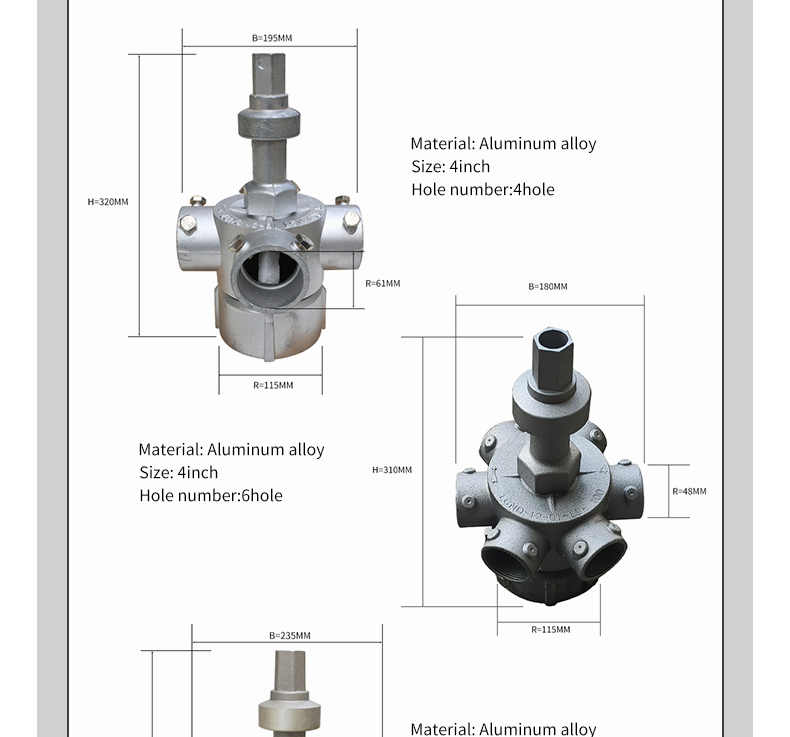

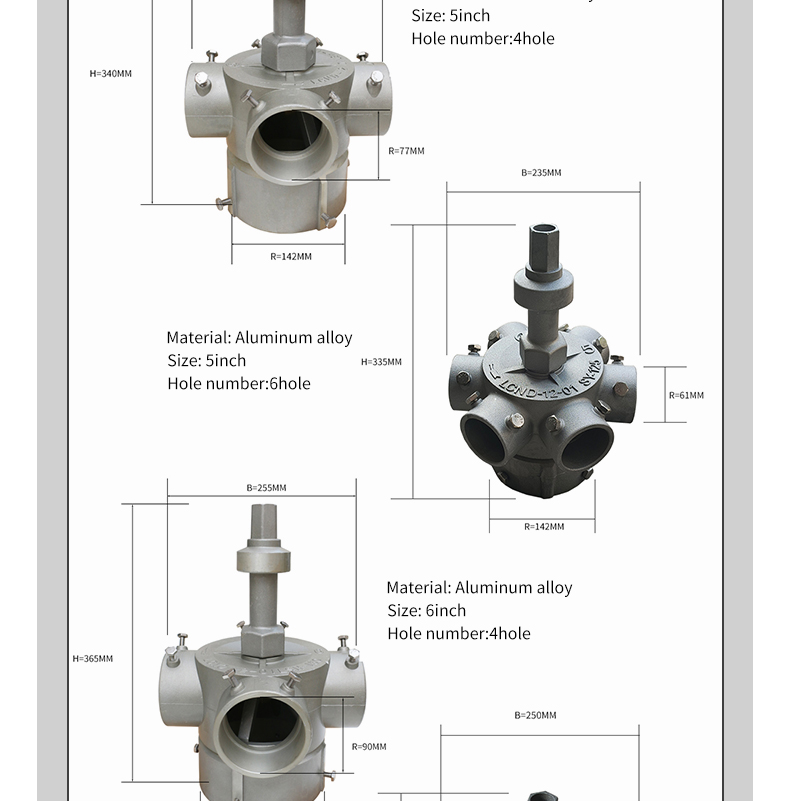

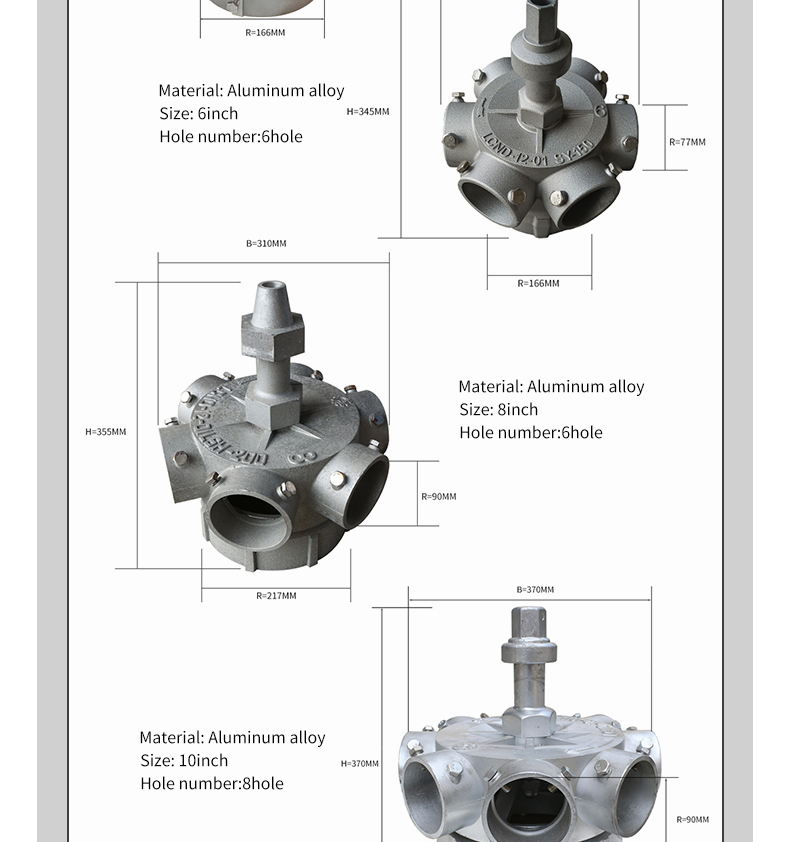

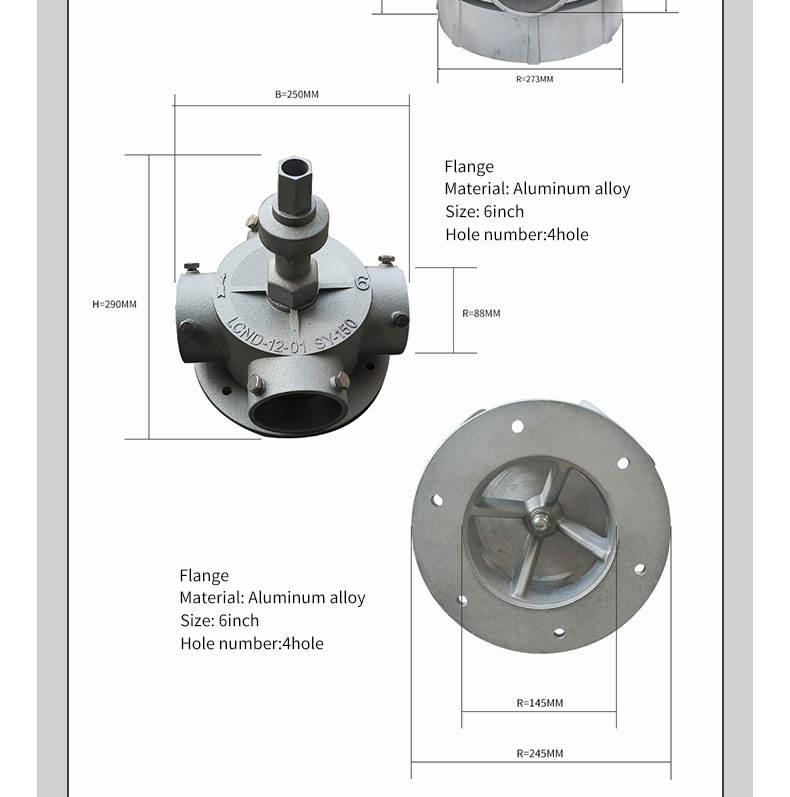

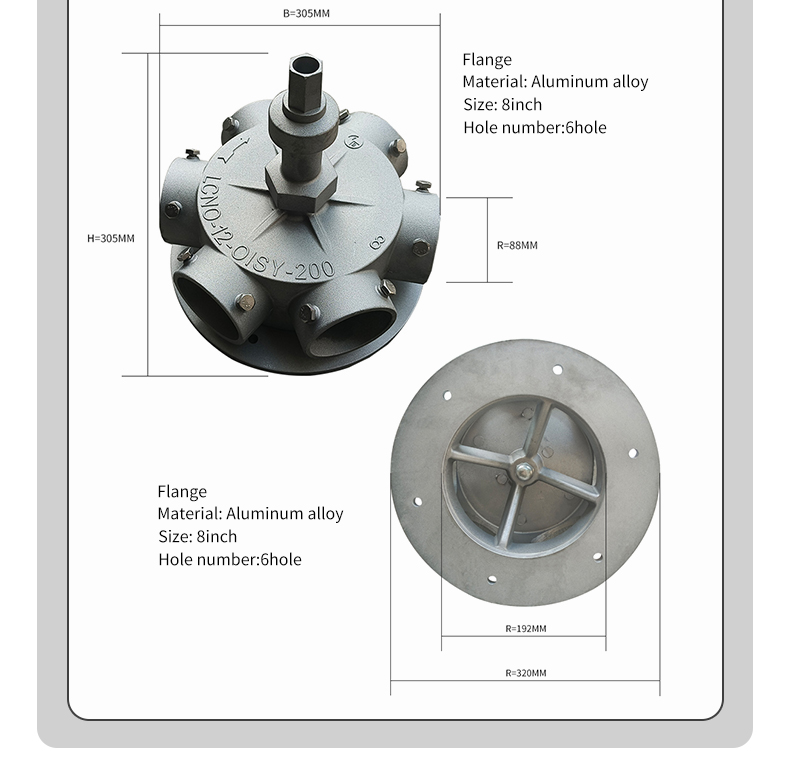

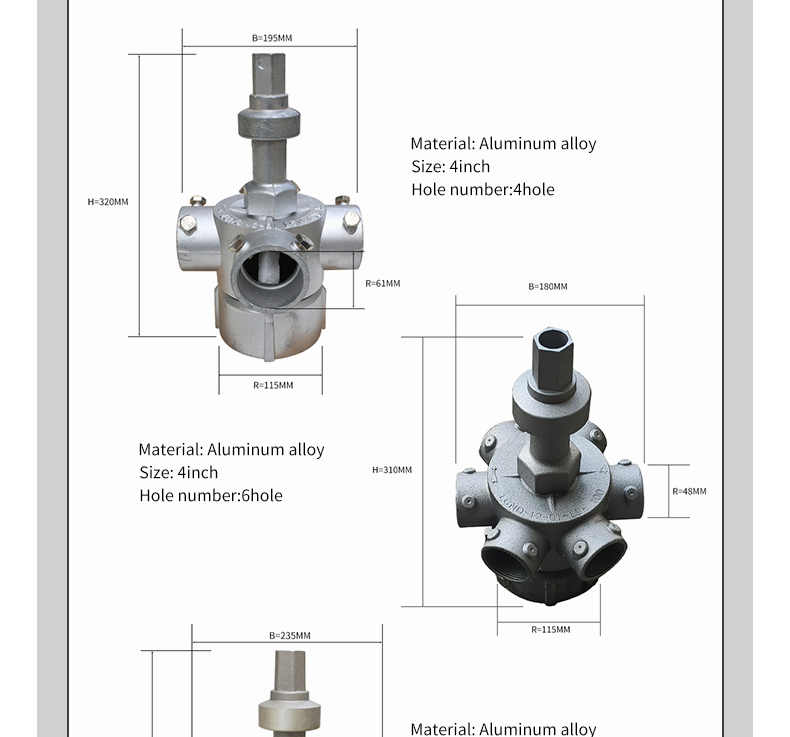

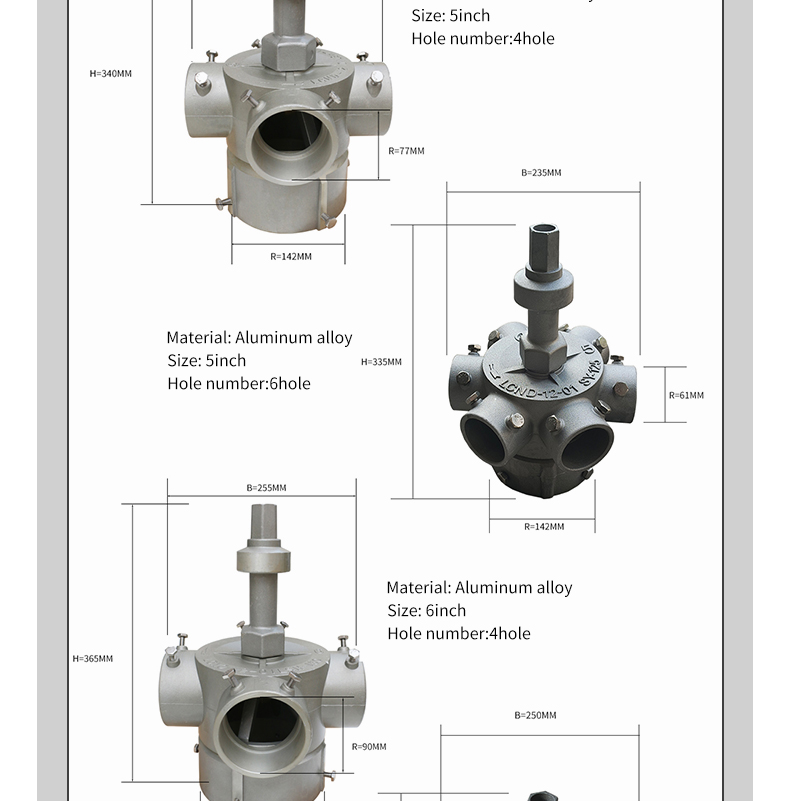

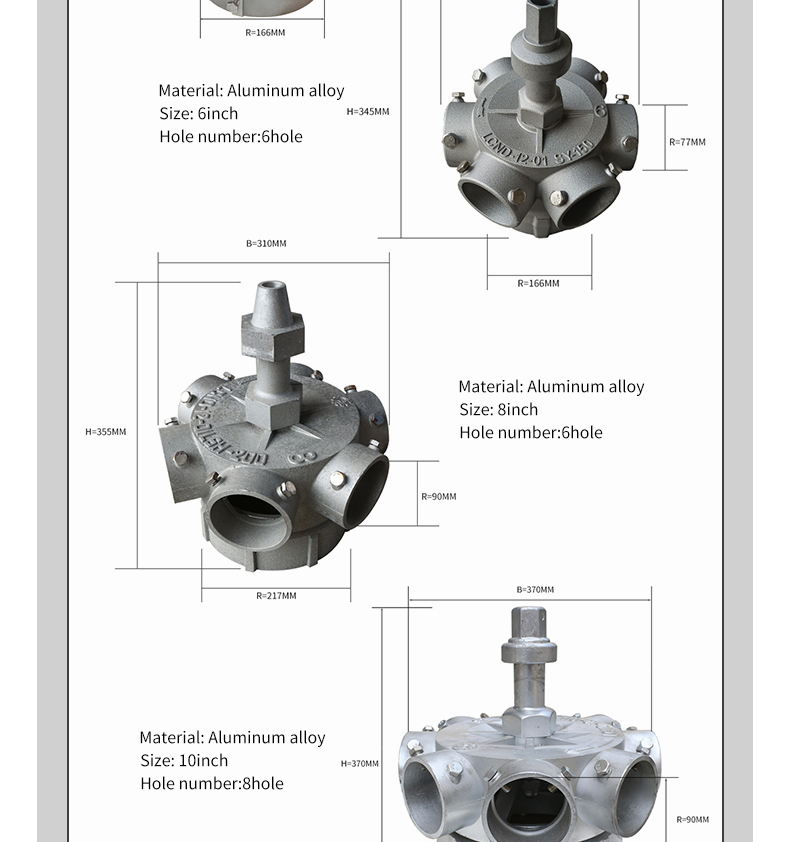

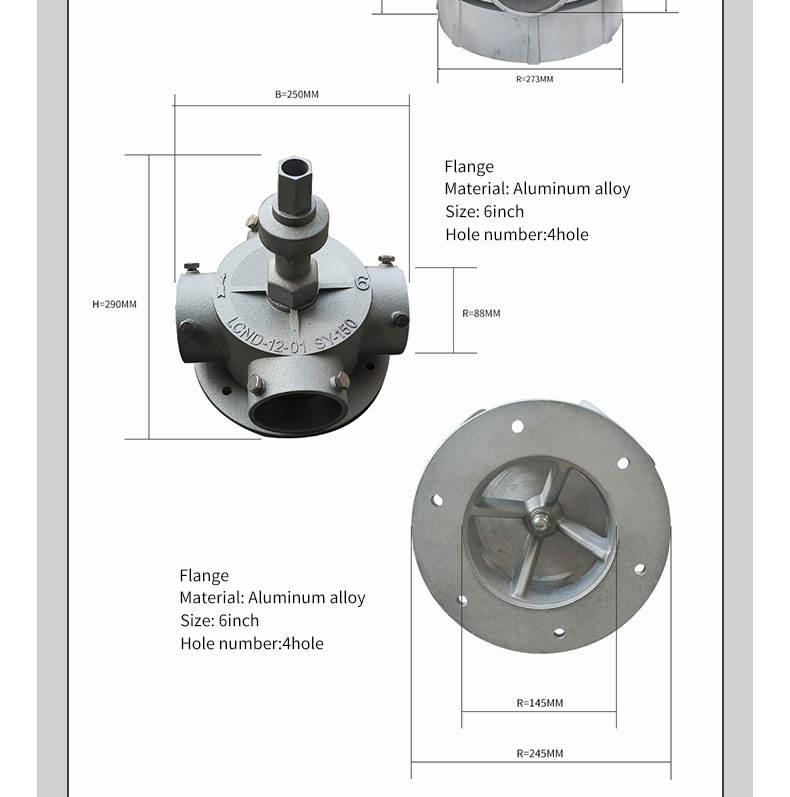

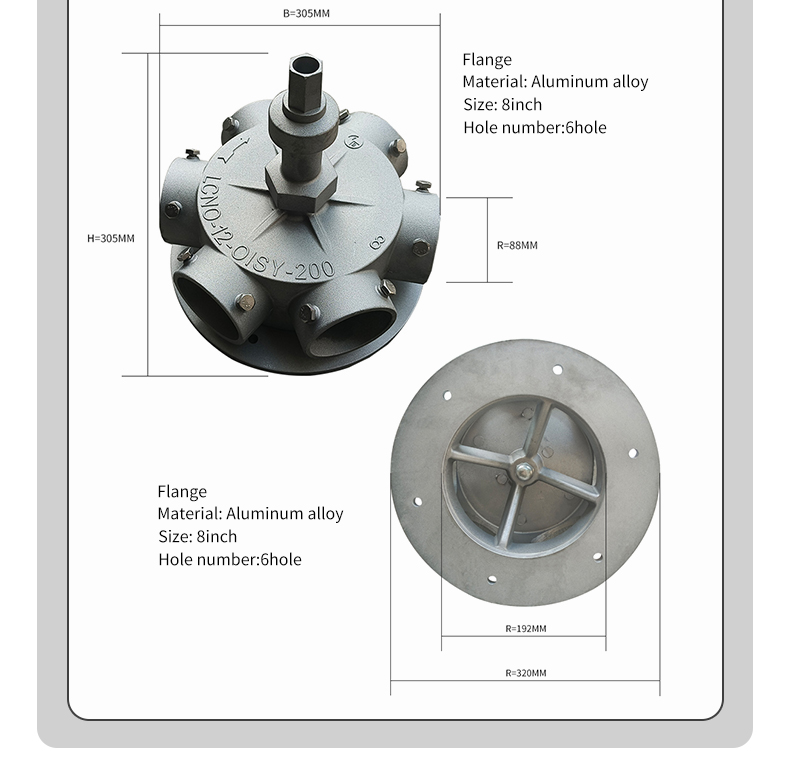

Aluminum Cooling Tower Sprinkler Head Specification

| Sprinkler head specification | Number of holes | Large caliber | Small caliber | Notes |

| 4 inch 4 holes | 4 | 115mm | 61mm | Large hole optional, small hole toothless |

| 4 inch 6 holes | 6 | 115mm | 48mm | Large hole optional, small hole with teeth |

| 5 inch 4 holes | 4 | 142mm | 77mm | Large hole optional, small hole with teeth

|

| 5 inch 6 holes | 6 | 142mm | 61mm |

| 6 inch 4 holes | 4 | 166mm | 90mm |

| 6 inch 6 holes | 6 | 166mm | 77mm |

| 8 inch 6 holes | 6 | 217mm | 90mm |

| 10 inch 6 holes | 6 | 273mm | 110mm |

| 10 inch 8 holes | 8 | 273mm | 90mm |

| 12 inch 10 holes | 10 | 320mm | 110mm |

Aluminum Cooling Tower Sprinkler Head Features

Aluminum Cooling Tower Sprinkler Head Material Properties

Aluminum alloy is a lightweight, high-strength, and corrosion-resistant metal material with the following significant features:

-

Aluminum Cooling Tower Sprinkler Head Low Density:

With a density of approximately 2.7 g/cm³, aluminum alloy is only one-third the weight of steel. This makes aluminum alloy water distributors much lighter and easier to handle, reducing the overall weight of the equipment and facilitating transportation and installation. -

Aluminum Cooling Tower Sprinkler Head High Strength:

Aluminum alloy possesses high mechanical strength, capable of withstanding significant water flow impact and working pressure. This ensures the stability and reliability of the water distributor during long-term use. -

Aluminum Cooling Tower Sprinkler Head Corrosion Resistance:

The surface of aluminum alloy typically forms a dense oxide layer that effectively resists corrosion from acids, alkalis, salts, and other corrosive substances in water, extending the service life of the water distributor. -

Aluminum Cooling Tower Sprinkler Head Good Machinability:

Aluminum alloy can be processed through various methods such as casting, extrusion, and welding. This allows for the production of complex structures and shapes to meet the design requirements of different water treatment equipment. -

Aluminum Cooling Tower Sprinkler Head Aesthetic Quality:

Aluminum alloy has a smooth surface and uniform color, providing good visual quality and enhancing the overall appearance of the equipment.

Aluminum Cooling Tower Sprinkler Head Structural Design

The structural design of aluminum alloy water distributors typically considers the following aspects:

-

Aluminum Cooling Tower Sprinkler Head Integrated Design:

Aluminum alloy water distributors are often manufactured using integrated casting or welding processes. The compact structure reduces the number of connection points, enhancing the strength and sealing performance of the distributor. This prevents leakage and uneven water distribution caused by loose connections. -

Aluminum Cooling Tower Sprinkler Head Uniform Water Distribution Holes:

The surface or interior of the distributor features multiple uniformly distributed holes. The size and spacing of these holes are precisely calculated to ensure that water is evenly distributed in all directions. This prevents localized high or low water flow, improving filtration efficiency and water quality. -

Aluminum Cooling Tower Sprinkler Head Anti-clogging Design:

To prevent clogging of the holes by impurities, aluminum alloy water distributors often incorporate special anti-clogging features. For example, filters may be placed at the entrance of the holes, or the holes may be designed at an angle to prevent impurities from entering and ensure long-term stable operation. -

Aluminum Cooling Tower Sprinkler Head Adjustability:

Some aluminum alloy water distributors are designed with adjustable features. Depending on different water treatment requirements and equipment operating conditions, the water distributor can be fine-tuned by adjusting the hole opening or the angle of the distributor to achieve optimal water distribution.

Aluminum Cooling Tower Sprinkler Head Water Distribution Performance

-

Aluminum Cooling Tower Sprinkler Head Uniformity:

Aluminum alloy water distributors can evenly distribute water across filtering media or packing materials. This ensures that water is uniformly spread throughout the filter layer, preventing localized overloading and clogging of the filtering media. Uniform water distribution improves filtration efficiency and extends the service life of the filtering media. -

Aluminum Cooling Tower Sprinkler Head Stability:

Thanks to the high strength and good mechanical properties of aluminum alloy, the water distributor maintains stable water distribution during operation. It is unaffected by water flow impact, pressure changes, or other factors. Even under high-flow and high-pressure conditions, it ensures uniform water distribution. -

Aluminum Cooling Tower Sprinkler Head Adaptability:

Aluminum alloy water distributors can be custom-designed to meet various water treatment processes and equipment requirements. They can adapt to complex operating conditions, such as different water qualities, temperatures, flow rates, and pressures. Their good corrosion resistance and mechanical properties ensure stable performance in various water treatment environments.

Aluminum Cooling Tower Sprinkler Head Installation and Maintenance

-

Aluminum Cooling Tower Sprinkler Head Easy Installation:

Aluminum alloy water distributors are lightweight, making them easy to transport and install. Their compact structure allows for a simple and quick installation process, typically requiring only basic tools and operations. This significantly reduces installation time and labor costs. -

Aluminum Cooling Tower Sprinkler Head Convenient Maintenance:

The smooth surface of aluminum alloy water distributors makes them less prone to impurity adhesion and fouling, making cleaning and maintenance relatively easy. If clogging or failure occurs, the simple structure of the distributor facilitates easy repair and low-cost replacement of parts. -

Aluminum Cooling Tower Sprinkler Head Long Service Life:

The corrosion resistance and high strength of aluminum alloy ensure a long service life in water treatment environments, typically over 10 years. This reduces the frequency of equipment replacement and maintenance costs.

Aluminum Cooling Tower Sprinkler Head Applications

Aluminum alloy water distributors are widely used in various water treatment equipment and systems. Common applications include:

-

Aluminum Cooling Tower Sprinkler Head Cooling Towers:

In cooling towers, aluminum alloy water distributors evenly distribute cooling water over the packing material, increasing the contact area between water and air. This improves cooling efficiency and reduces the temperature of the cooling water. -

Aluminum Cooling Tower Sprinkler Head Filters:

In multi-media filters, activated carbon filters, sand filters, and other equipment, aluminum alloy water distributors evenly distribute water across the filtering media. This improves filtration effectiveness, prevents clogging of the filtering media, and extends the service life of the filter. -

Aluminum Cooling Tower Sprinkler Head Ion Exchangers:

In ion exchangers, aluminum alloy water distributors evenly distribute regenerant liquid, ensuring full contact between ion exchange resins and the regenerant. This improves regeneration effectiveness, ensuring the treatment capacity and water quality stability of the ion exchanger. -

Aluminum Cooling Tower Sprinkler Head Biological Filters:

In biological filters, aluminum alloy water distributors evenly distribute water over the biological packing material, providing a favorable growth environment for microorganisms. This improves biological treatment efficiency and removes organic matter and ammonia nitrogen from the water. -

Aluminum Cooling Tower Sprinkler Head Reverse Osmosis Systems:

In the pre-treatment systems of reverse osmosis, aluminum alloy water distributors are used in security filters and other equipment to ensure uniform water distribution. This protects the reverse osmosis membrane and improves the overall performance and stability of the system.

Cost-effectiveness

-

Aluminum Cooling Tower Sprinkler Head Cost Efficiency:

Aluminum alloy is relatively inexpensive and has mature manufacturing processes. Compared to stainless steel and other materials, aluminum alloy water distributors offer a cost advantage, reducing the initial investment cost of water treatment equipment. -

Aluminum Cooling Tower Sprinkler Head Low Operating Costs:

Aluminum alloy water distributors have a long service life and require minimal maintenance. They do not need frequent part replacements or complex maintenance operations, reducing operating and maintenance costs. Their good water distribution performance also improves water treatment efficiency, reduces energy consumption, and further lowers operating costs. -

Aluminum Cooling Tower Sprinkler Head Significant Energy Savings:

Uniform water distribution by aluminum alloy water distributors improves the efficiency of water treatment equipment. For example, in cooling towers, uniform water distribution enhances cooling efficiency, reducing the circulation flow rate of cooling water and saving pump energy.

Aluminum Cooling Tower Sprinkler Head Environmental Friendliness

-

Aluminum Cooling Tower Sprinkler Head Recyclability:

Aluminum alloy is a recyclable material with a high recycling rate and minimal environmental impact. At the end of its service life, the aluminum alloy components of the water distributor can be recycled and reused, reducing resource waste and environmental pollution. -

Aluminum Cooling Tower Sprinkler Head Non-toxicity:

Aluminum alloy is non-toxic and odorless, and it does not contaminate water quality. During water treatment, aluminum alloy water distributors do not release harmful substances, meeting environmental requirements and making them suitable for applications with high water quality demands, such as drinking water and food processing water.

Aluminum Cooling Tower Sprinkler Head Other Advantages

-

Aluminum Cooling Tower Sprinkler Head Good Thermal Conductivity:

Aluminum alloy has good thermal conductivity. In water treatment equipment where heat transfer is a consideration, such as cooling towers and heat exchangers, aluminum alloy water distributors can better support the heat exchange process and improve equipment efficiency. -

Aluminum Cooling Tower Sprinkler Head Impact Resistance:

Aluminum alloy has a certain degree of impact resistance. During the operation of water treatment equipment, it can withstand mechanical and water flow impacts without damage, ensuring normal operation. -

Aluminum Cooling Tower Sprinkler Head Good Electromagnetic Compatibility:

Aluminum alloy has good electromagnetic shielding properties. In water treatment equipment with electromagnetic requirements, such as electronic water treatment devices, aluminum alloy water distributors can effectively reduce electromagnetic interference and ensure normal equipment operation.

Aluminum Cooling Tower Sprinkler Head Future Development Trends

With the continuous advancement of water treatment technology and increasing environmental requirements, aluminum alloy water distributors are also being optimized and innovated. Future development directions may include the following aspects:

-

Aluminum Cooling Tower Sprinkler Head Development of High-Performance Aluminum Alloys:

Research and development of aluminum alloys with higher strength, better corrosion resistance, and high-temperature performance to meet the needs of different water treatment conditions and further enhance the performance and service life of water distributors. -

Aluminum Cooling Tower Sprinkler Head Intelligent Water Distribution Systems:

Combining advanced sensor technology with automated control technology to develop intelligent aluminum alloy water distributors. By real-time monitoring of water flow, water quality, pressure, and other parameters, the water distributor can automatically adjust the hole opening and distributor angle to achieve precise water distribution, improving water treatment efficiency and automation levels.

Aluminum Cooling Tower Sprinkler Head Application

The application range is: Industrial water cooling,Air compressor, Aluminum profile processing, Steam turbine, Power generation, Tannery, Electric furnace, Freezing Series, Air conditioning cooling system

Aluminum Cooling Tower Sprinkler Head Shipment

Packing:

In bundle,wooden pallet or as your request.

Delivery time:

With in 10 days.

Our Services Of Aluminum Cooling Tower Sprinkler Head

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.