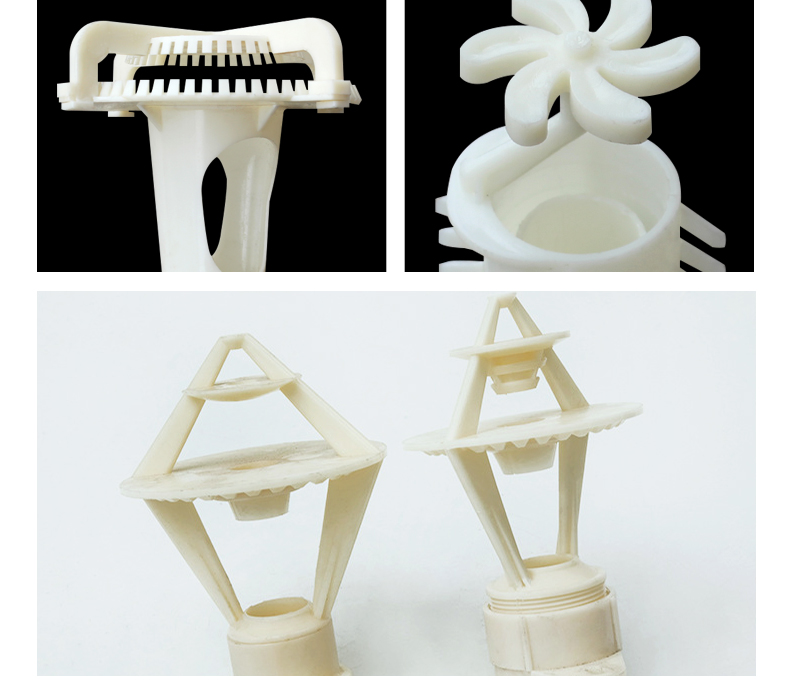

The ABS Cooling Tower Water Nozzle is made of ABS plastic by one-time injection molding, which has high strength and long service life. The nozzle distributes water evenly, and the working water pressure is low (the working pressure at the nozzle outlet is only 0.6H20), and the pressure adaptation range is wide, so it is not easy to block. Because it has a specially designed locking and anti-loosening device, it can be firmly connected with the water distribution pipe without falling off, which can ensure the long-term safe operation of the water distribution system. Under normal conditions, the service life of the head is 20 years.

When ABS Cooling Tower Water Nozzle Need To Be Replaced:

ABS Cooling Tower Water Nozzle Clogging

Cause: Over long-term operation, impurities, scale, and microorganisms in the water can adhere to the inside of the nozzles or the spray holes, leading to clogging.

Symptoms: Insufficient spray water volume and uneven distribution, resulting in reduced cooling efficiency.

Solution: If the nozzles are severely clogged and cannot be cleaned and unblocked, they need to be replaced.

ABS Cooling Tower Water Nozzle Wear or Damage

Cause: The nozzles may wear out or get damaged due to long-term exposure to water flow impact and corrosion.

Symptoms: The spray shape and water flow of the nozzles change, failing to meet the designed water distribution requirements.

Solution: Regularly inspect the condition of the nozzles. If they are severely worn or damaged, they should be replaced promptly.

ABS Cooling Tower Water Nozzle Spray Nozzles Aging

Cause: The durability of nozzle materials is limited. When exposed to high temperatures and high humidity for a long time, the nozzles will gradually age.

Symptoms: The performance of the nozzles declines, such as reduced water flow and altered spray angles.

Solution: Even if the nozzles do not show obvious damage, they should be replaced regularly based on their service life and actual operating conditions.

ABS Cooling Tower Water Nozzle Uneven Water Distribution

Cause: Nozzle blockage, damage, aging, and deformation of the water distribution pipes can all lead to uneven water distribution.

Symptoms: The heat exchange effect of the cooling tower packing layer deteriorates. Some parts of the packing do not have enough water coverage, resulting in dry spots.

Solution: Inspect the condition of the nozzles, clean or replace the clogged or damaged ones, and check whether the water distribution pipes are tilted or deformed. If necessary, repair or replace them.

ABS Cooling Tower Water Nozzle Reduced Cooling Efficiency

Cause: Problems with the nozzles lead to poor water flow, distribution, and spray effect of the spray water, affecting the heat exchange efficiency of the cooling tower.

Symptoms: The temperature of the cooled water does not meet the design requirements, and the system operating efficiency decreases.

Solution: Inspect the nozzles for blockages, wear, or aging. If problems are found, replace the nozzles promptly.

ABS Cooling Tower Water Nozzle Material Not Suitable for Water Quality

Cause: If the water quality of the cooling tower is poor and contains a large amount of corrosive substances, and the nozzle material is not corrosion-resistant, the nozzles will be corroded and damaged.

Symptoms: Cracks, holes, or deformation appear in the nozzles.

Solution: Replace the nozzles with materials that have better corrosion resistance, such as stainless steel or engineering plastics.

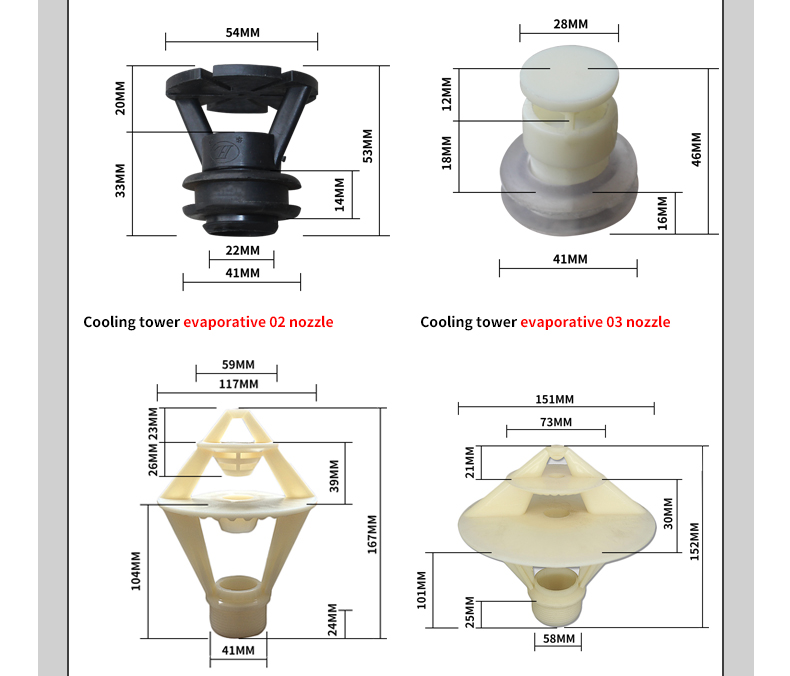

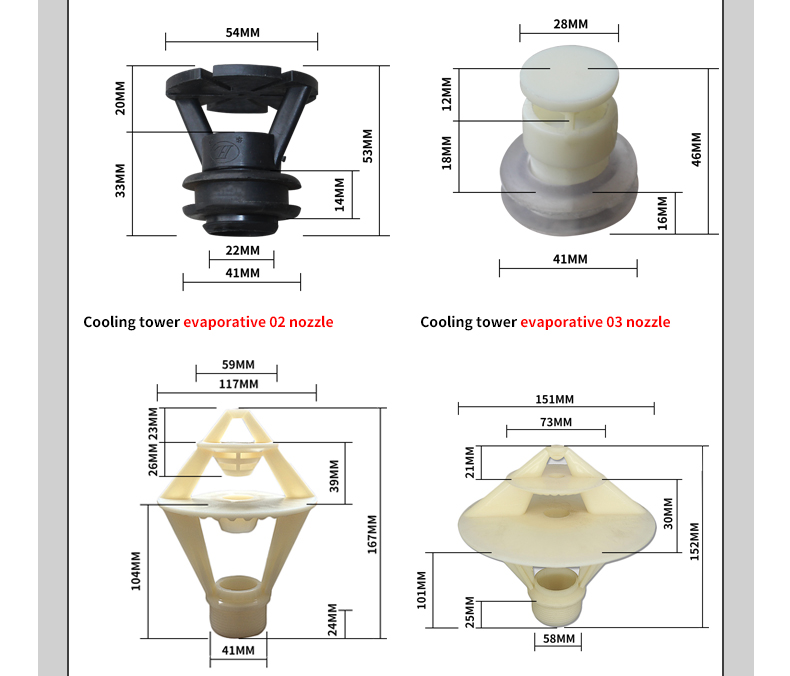

ABS Cooling Tower Water Nozzle Specification

ABS Cooling Tower Water Nozzle Features

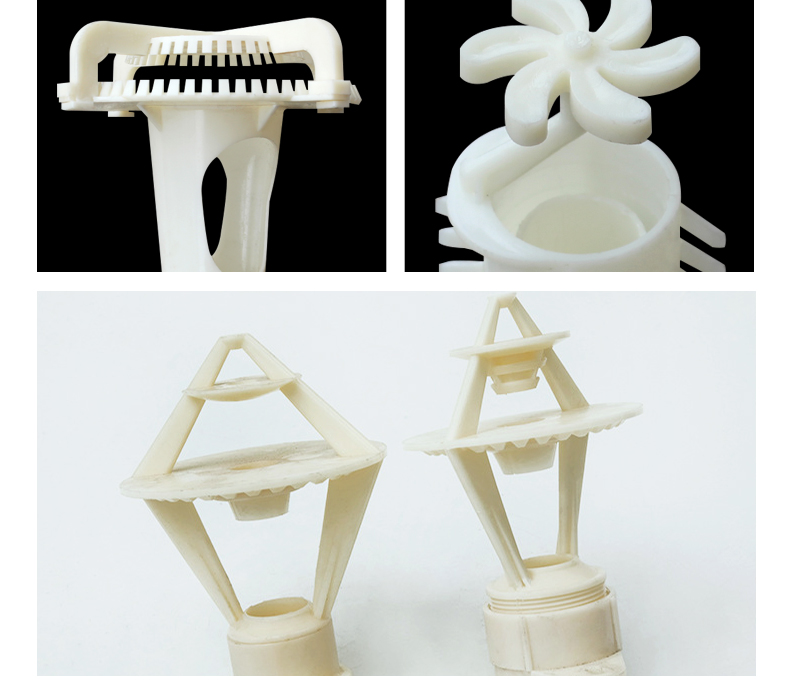

Cooling tower nozzles are a key component of cooling tower systems, and their performance directly affects the cooling efficiency and overall system effectiveness. Here are the main characteristics of cooling tower nozzles:

1. ABS Cooling Tower Water Nozzle Flow Coefficient and Working Pressure Adaptability

-

ABS Cooling Tower Water Nozzle Flow Coefficient:

Different types of nozzles have different flow coefficients. For example, the XPH nozzle has a lower flow coefficient (0.368) and is suitable for working water head pressures ≥10 kPa. In contrast, the TP-II nozzle has a higher flow coefficient (0.921) and requires nozzle combinations to achieve uniform water distribution. -

ABS Cooling Tower Water Nozzle Working Pressure Adaptability:

The splash radius of a nozzle increases with the working water head pressure and the height of the water falling. For example, when the working water head pressure is 10 kPa and the falling height is 0.8 m, the splash radius of the XPH nozzle is 1.1 m, while that of the TP-II nozzle is 1.6 m.

2. ABS Cooling Tower Water Nozzle Splash Range and Uniformity

-

ABS Cooling Tower Water Nozzle Splash Range:

The splash range is an important characteristic of nozzles. For example, the XPH nozzle has a smaller splash range and is suitable for use in the wall areas of the cooling tower, while the TP-II nozzle has a larger splash range and is suitable for the middle and central areas of the cooling tower. -

ABS Cooling Tower Water Nozzle Splash Uniformity:

The uniformity of the splash directly affects the cooling effect. The TP-II nozzle has a better splash uniformity coefficient (0.16) compared to the XPH nozzle (0.28). Additionally, the arrangement of nozzles also affects splash uniformity. For example, the TP-II nozzle arranged in a square pattern achieves the best splash uniformity when the water flow is between 6.8 and 9.5 m³/h.

3. ABS Cooling Tower Water Nozzle Droplet Size and Cooling Effect

-

ABS Cooling Tower Water Nozzle Droplet Size:

The size of droplets produced by the nozzle affects the cooling effect. Smaller droplets increase the contact area between water and air, thereby improving cooling efficiency. For example, atomizing nozzles can convert cooling water pressure into tiny droplets with diameters between 100 and 300 micrometers, achieving highly efficient cooling. -

ABS Cooling Tower Water Nozzle Cooling Effect:

The design and performance of the nozzle directly affect the cooling efficiency of the cooling tower. Efficient nozzles can spray hot water evenly into fine droplets, increasing the contact area between water and air and thus improving cooling efficiency.

4. ABS Cooling Tower Water Nozzle Corrosion Resistance and Anti-Clogging Design

-

ABS Cooling Tower Water Nozzle Corrosion Resistance:

Cooling tower nozzles are typically made from corrosion-resistant materials, such as polypropylene (PP) or stainless steel, to withstand the harsh working environment inside the cooling tower. -

ABS Cooling Tower Water Nozzle Anti-Clogging Design:

Nozzles are designed to prevent clogging. For example, the NS5 nozzle has no internal components or narrow passages, effectively preventing clogging by fibrous impurities.

5. ABS Cooling Tower Water Nozzle Installation and Maintenance

-

ABS Cooling Tower Water Nozzle Easy Installation:

Many cooling tower nozzles are designed for easy installation and replacement. For example, the Marley NS nozzle can be installed into the matching pipe without tools. -

ABS Cooling Tower Water Nozzle Low Maintenance Cost:

Nozzles made from high-quality materials have a long service life and low maintenance frequency, reducing maintenance costs.

6. ABS Cooling Tower Water Nozzle Energy and Water Conservation

-

ABS Cooling Tower Water Nozzle Energy Saving:

Efficient nozzles can improve the cooling efficiency of the cooling tower, thereby reducing energy consumption. -

ABS Cooling Tower Water Nozzle Water Conservation:

By optimizing the spray effect of the nozzle, water usage can be reduced, achieving water-saving effects.

ABS Cooling Tower Water Nozzle Application

The application range is: Industrial water cooling,Air compressor, Aluminum profile processing, Steam turbine, Power generation, Tannery, Electric furnace, Freezing Series, Air conditioning cooling system

ABS Cooling Tower Water Nozzle Shippment

Packing:

Wooden,cartons,custom package.

Delivery time:

With in 10 days.

Our Services Of ABS Cooling Tower Water Nozzle

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.