Description of Cooling Tower Sprinkler Head

The cooling tower sprinkler head is a key component in a round cooling tower, mainly used to evenly distribute cooling water onto the filler layer, promote evaporation and heat dissipation by increasing the contact area between water and gas, and thus reduce water temperature.

Working Principle of Cooling Tower Sprinkler Head

The working principle of the cooling tower sprinkler head is to evenly spray water onto the surface of the fill inside the cooling tower, thereby increasing the contact area between water and air and promoting water evaporation cooling. Water enters the sprinkler head from the top or side of the tower, and is dispersed into small water droplets through the nozzles or nozzles in the distributor, evenly covering the surface of the fill material and forming a thin water film. When hot water passes through the fill, it exchanges heat with the air, and the heat in the water is carried away by evaporation, thereby reducing the water temperature. The design of the sprinkler head in a cooling tower usually considers the uniform distribution of water flow, the coverage range of the nozzle, the spraying angle, and the pressure of the water flow to ensure that the water distribution in the entire filling area is uniform, avoiding situations where the local water volume is too much or too little, which helps to improve cooling efficiency and energy-saving effect. An effective sprinkler head can not only improve the heat exchange performance of the cooling tower, but also prevent a decrease in cooling effect caused by uneven or blocked water flow.

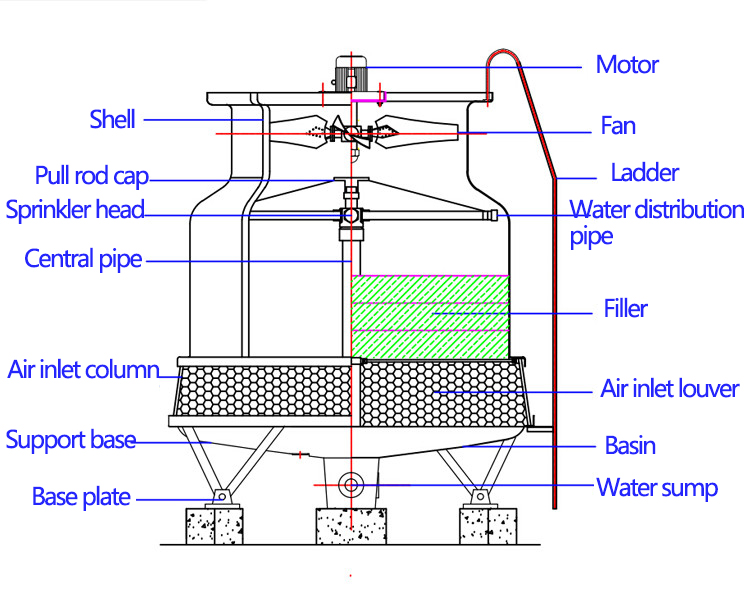

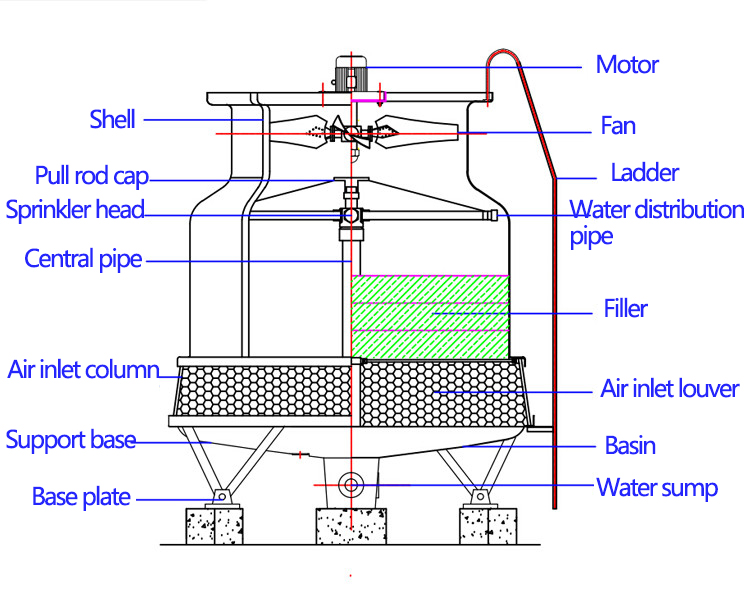

Structural Diagram of Sprinkler Head In Cooling Tower

Advantages of Cooling Tower Sprinkler Head

Cooling tower sprinkler head is one of the key components in a cooling tower, responsible for evenly distributing water on the fill of the cooling tower, ensuring effective contact between air and water. Its advantages include:

1.Uniform water distribution:

The sprinkler head can evenly spray water onto the fill of the cooling tower, increasing the contact area between water and air, thereby improving cooling efficiency.

2.Improve cooling efficiency:

By optimizing the water distribution method, the cooling tower can more effectively lower the water temperature and improve the overall heat exchange efficiency of the system.

3. Energy saving and consumption reduction:

Due to the sprinkler head of the cooling tower providing a more uniform water flow distribution, the unevenness of the water flow is reduced, which can reduce energy consumption and improve the efficiency of the water circulation system.

4. Preventing blockage:

Reasonably design to reduce the erosion of water flow on the filling material and reduce the risk of blockage.

5. Strong adaptability:

The design of the sprinkler head can be adjusted according to the needs of different cooling towers, adapting to cooling tower systems of different sizes and types.

6. Simple structure, easy installation and maintenance:

Sprinkler heads generally have a simple structure, easy installation and maintenance, and a long service life.

7. Extend equipment lifespan:

Uniform water distribution reduces component impact and wear, extending the service life of cooling towers

Material of Cooling Tower Sprinkler Head

Cooling tower sprinkler head (also known as nozzle or distributor) is an important component of cooling towers. Its function is to evenly spray water onto the filler to enhance the contact between water and air and improve cooling efficiency. There are several common materials for cooling water heaters, including:

1.ABS Type

ABS has strong corrosion resistance and can resist most chemicals in water, making it suitable for use in common industrial cooling water environments.

2.Aluminum alloy type

Aluminum alloy water heaters have high strength and good corrosion resistance, and are commonly used in cooling towers that require lightweight and sturdy structures. Suitable for seawater cooling or highly corrosive environments.

3.Nylon type

Nylon has relatively good high temperature resistance and can withstand water temperatures up to around 80 ° C (depending on the specific type of nylon). Therefore, nylon cloth water heaters are suitable for most industrial cooling towers, especially in applications where the temperature is not particularly high.

Application Scope of Cooling Tower Sprinkler Head

1.Industrial cooling system:

Cooling tower sprinkler heads are widely used in various industrial fields, especially in industries that require a large amount of cooling water, such as power, chemical, metallurgical, mechanical, petrochemical, etc. In these industries, cooling towers are used to reduce equipment temperature and maintain stable process operation.

2. Air conditioning system:

In the air conditioning cooling system of large buildings or commercial centers, the sprinkler head also plays an important role in helping the system improve cooling efficiency and reduce energy consumption.

3. Water treatment facilities:

In some water treatment and circulating water systems, sprinkler head can help improve water temperature regulation and water quality purification, reducing water resource waste.

4. Cooling tower under low load conditions:

The sprinkler head is also suitable for cooling towers under low load conditions, especially in energy-saving designs. Optimizing the water distribution effect can improve the performance of the system under different operating conditions.

5. Efficient and energy-saving cooling tower:

In projects that require high efficiency, energy conservation, and environmental protection, the design of sprinkler heads may also consider the uniformity of water droplet spraying and evaporation, thereby improving the overall system's heat exchange efficiency

PT company produces various specifications and materials of sprinkler head, with ample stock available. Please feel free to inquire~