When it comes to cooling tower efficiency, few components punch above their weight like FRP cooling tower fans. They’re lightweight, tough, corrosion-resistant, and incredibly efficient. That’s why industries worldwide are actively searching for top FRP cooling tower fan suppliers who can deliver performance without headaches.

If metal fans are the old workhorse, FRP fans are the modern racehorse—faster, lighter, and built for endurance. Let’s explore who the best suppliers are, why FRP fans dominate today’s market, and how to choose the right partner for your project.

Introduction to FRP Cooling Tower Fans

FRP cooling tower fans are designed to move large volumes of air through the cooling tower using fiber-reinforced plastic (FRP) materials. Their job sounds simple, but the engineering behind them is anything but.

Every curve, angle, and gram of material affects airflow, energy use, noise, and reliability.

What Is FRP and Why It Matters in Cooling Towers

FRP—short for Fiber Reinforced Plastic—is a composite made from glass fibers and resin. The result? A material that’s:

* Strong but lightweight

* Highly corrosion-resistant

* Electrically non-conductive

* Ideal for wet and chemical environments

In cooling towers, where moisture and chemicals are constant threats, FRP isn’t a luxury—it’s a necessity.

Why FRP Fans Are Replacing Traditional Metal Fans

Metal fans had their moment, but times have changed.

FRP fans outperform metal fans by:

* Reducing load on gearboxes and motors

* Lowering energy consumption

* Eliminating rust and corrosion

* Cutting down maintenance costs

Think of it as switching from a steel bicycle to a carbon-fiber one—same job, far better performance.

Global Market Overview for FRP Cooling Tower Fans

The global demand for FRP cooling tower fans is booming, driven by:

* Power generation expansion

* Petrochemical projects

* Data centers and HVAC growth

* Energy efficiency regulations

Suppliers from Asia—especially China—now dominate this space thanks to scale, innovation, and cost efficiency.

Key Benefits of Choosing FRP Cooling Tower Fans

Lightweight Structure

FRP fans are up to 40% lighter than metal alternatives, reducing mechanical stress and extending equipment life.

Corrosion Resistance

No rust. No flaking. No surprise failures. FRP thrives where metal struggles.

Energy Efficiency

Optimized blade profiles mean more airflow with less power—saving real money year after year.

Long Service Life

With proper design and balancing, FRP fans can last 15–20 years or more.

Types of FRP Cooling Tower Fans

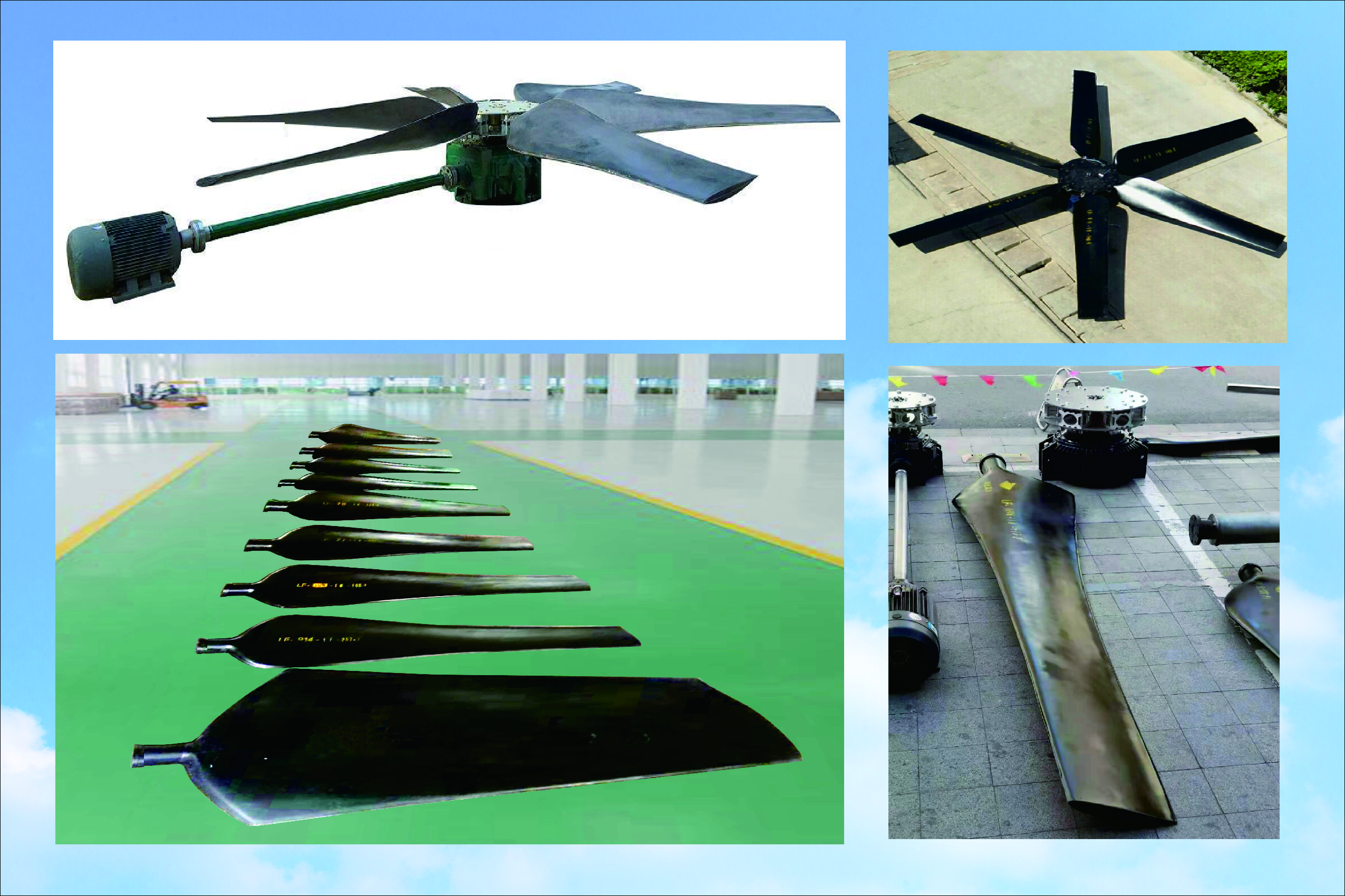

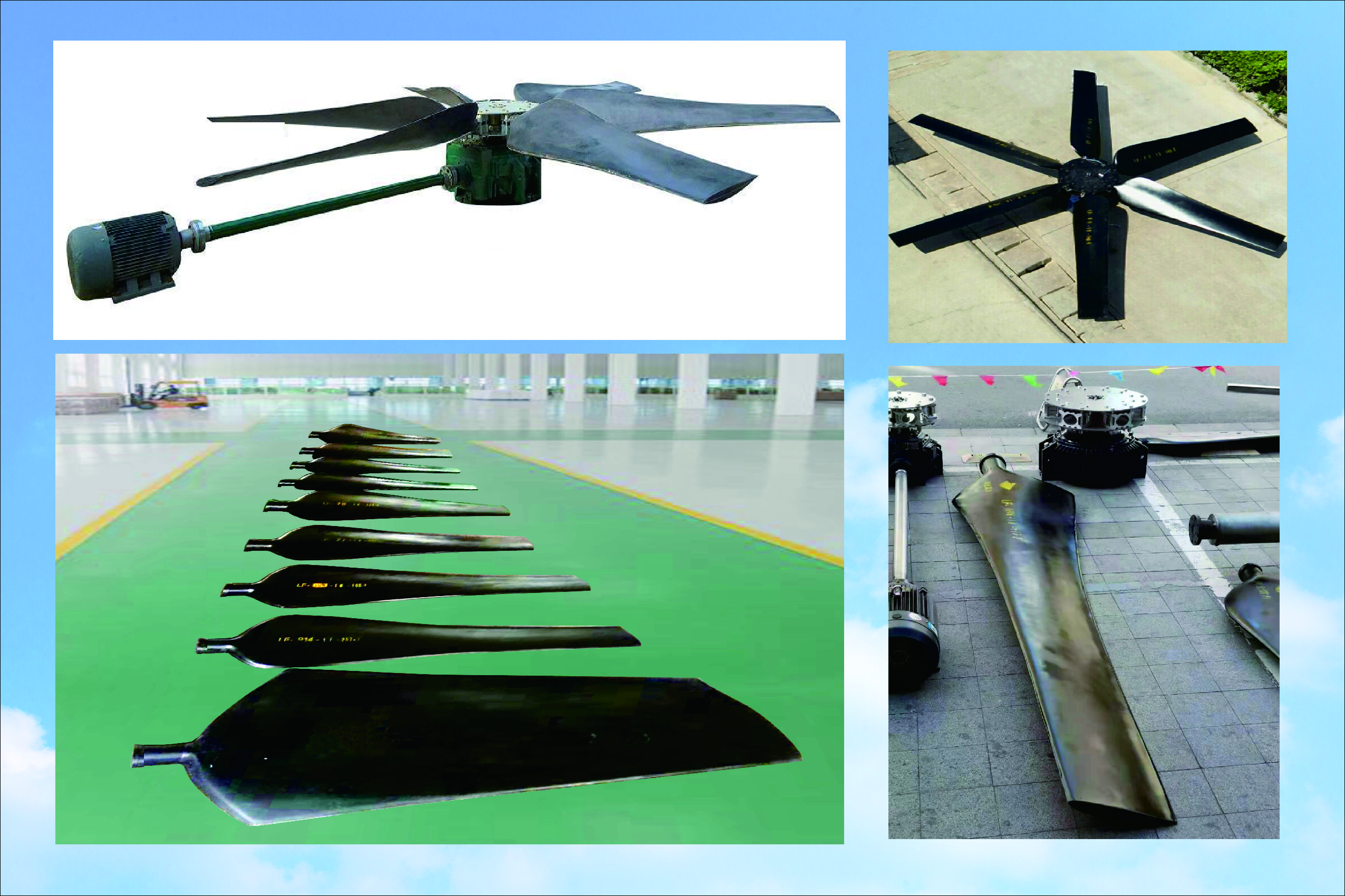

Axial FRP Cooling Tower Fans

The most common type, axial FRP fans move massive air volumes at low pressure—perfect for industrial cooling towers.

Induced Draft FRP Fans

Installed at the top of cooling towers, these fans pull air upward, improving thermal performance and efficiency.

Custom Molded FRP Fan Blades

Top suppliers offer custom blade designs to match airflow, noise, and structural requirements.

FRP Fan Aerodynamic Design Fundamentals

Blade Profile and Pitch Angle

Blade pitch controls airflow and power consumption. Too aggressive? Energy waste. Too shallow? Poor cooling.

Airflow Optimization

Modern FRP fans use CFD (Computational Fluid Dynamics) to fine-tune performance.

Noise Reduction Techniques

Advanced blade tips and smooth surfaces reduce turbulence—and noise complaints.

Manufacturing Process of FRP Cooling Tower Fans

Material Selection and Resin Systems

High-quality suppliers use premium glass fibers and vinyl ester or epoxy resins for durability.

Molding and Curing Process

Precision molds ensure consistency, while controlled curing guarantees structural integrity.

Dynamic Balancing and Inspection

Every fan is dynamically balanced to minimize vibration and extend bearing life.

Quality Standards and Certifications

Top FRP cooling tower fan suppliers comply with:

* ISO 9001

* CE standards

* AMCA performance guidelines

Quality isn’t optional—it’s built into every blade.

Top FRP Cooling Tower Fan Suppliers

Seagull Cooling Group

A global supplier known for high-efficiency FRP fans used in power and petrochemical plants worldwide.

Liangchi Industry

Liangchi offers premium FRP fan solutions with excellent airflow efficiency and noise control.

Power Tower Cooling Technology (Shaoxing) Co.,Ltd

Specializes in large-diameter FRP fans with strong OEM and customization capability.

Comparison – FRP Fan Suppliers vs Aluminum Fan Suppliers

FRP fan suppliers offer:

* Better corrosion resistance

* Lower weight

* Higher energy efficiency

Aluminum fans still have niche uses, but FRP dominates modern cooling towers.

Industries That Depend on FRP Cooling Tower Fans

Power Generation Industry

Efficient cooling directly impacts turbine performance and output stability.

Petrochemical and Chemical Plants

FRP fans withstand harsh chemicals where metal simply fails.

HVAC and Commercial Buildings

Low-noise FRP fans are ideal for urban installations.

Steel and Metallurgy Industry

Heavy-duty FRP fans handle heat, dust, and continuous operation.

How to Choose the Right FRP Cooling Tower Fan Supplier

Technical Capability

Look for aerodynamic design expertise and testing data.

Customization and OEM Support

Top suppliers tailor fan diameter, pitch, hub type, and mounting.

Export Experience

Global shipping experience reduces risk and delays.

Common FRP Fan Problems and Supplier Solutions

Issues like imbalance or cracking are solved through better resin systems, reinforced blade roots, and precision balancing.

Frequently Asked Question

Are FRP cooling tower fans safe?

Yes, when designed and balanced correctly.

Can FRP fans replace metal fans?

In most applications, absolutely.

Do suppliers offer custom designs?

Yes—customization is a major advantage.

Final Conclusion

Choosing from the top FRP cooling tower fan suppliers is about more than price—it’s about efficiency, reliability, and long-term value. With advanced materials, optimized aerodynamics, and proven performance, FRP fans are the future of cooling tower technology.