Introduce To Cooling Tower Fill

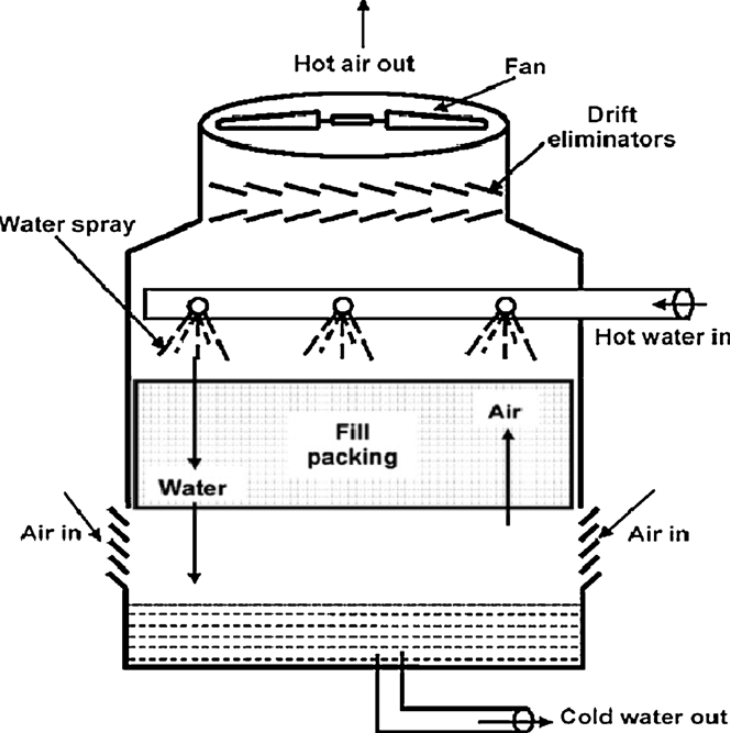

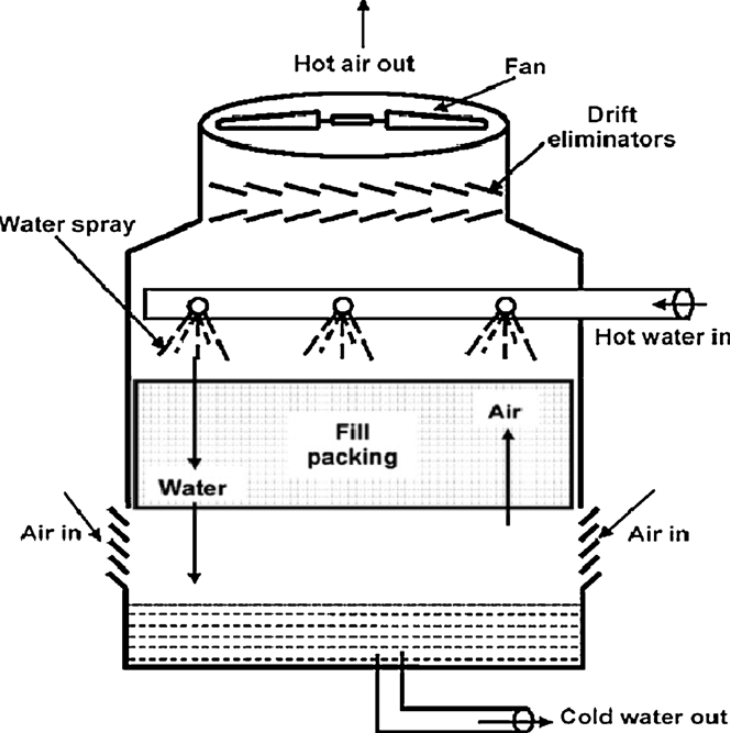

Cooling tower fill (also known as tower fill, tower core, cooling medium Fill Media) is one of the most core internal components in a cooling tower. Its function is to expand the contact area between water and air, extend the heat exchange contact time, and improve the evaporative cooling efficiency.

It can be said that the performance of the fill largely determines the cooling effect and energy consumption level of the cooling tower.

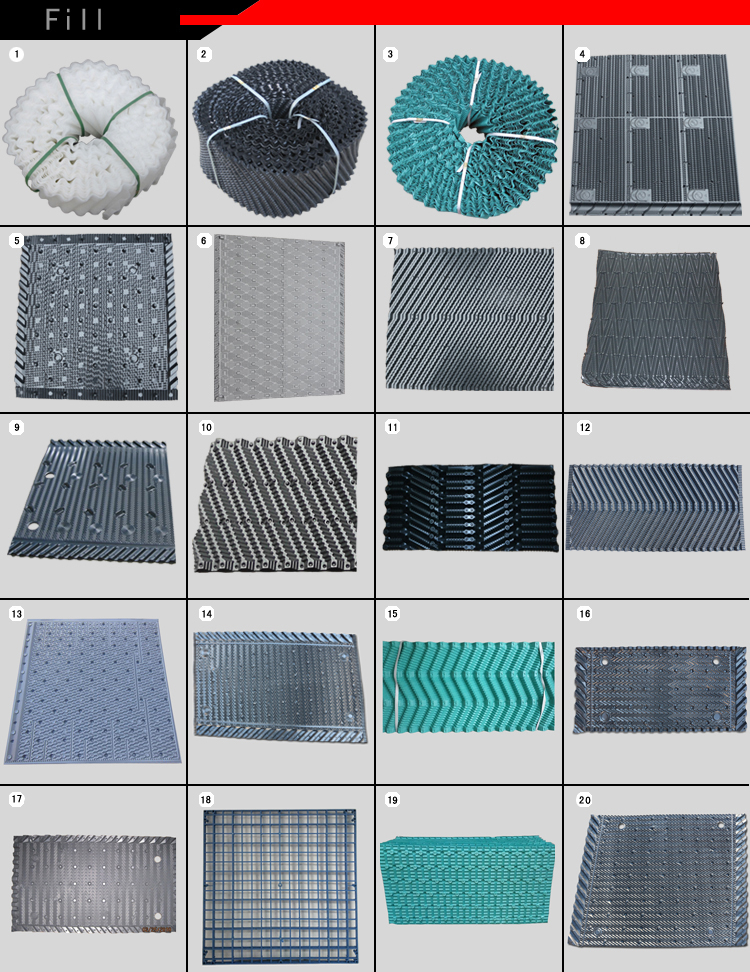

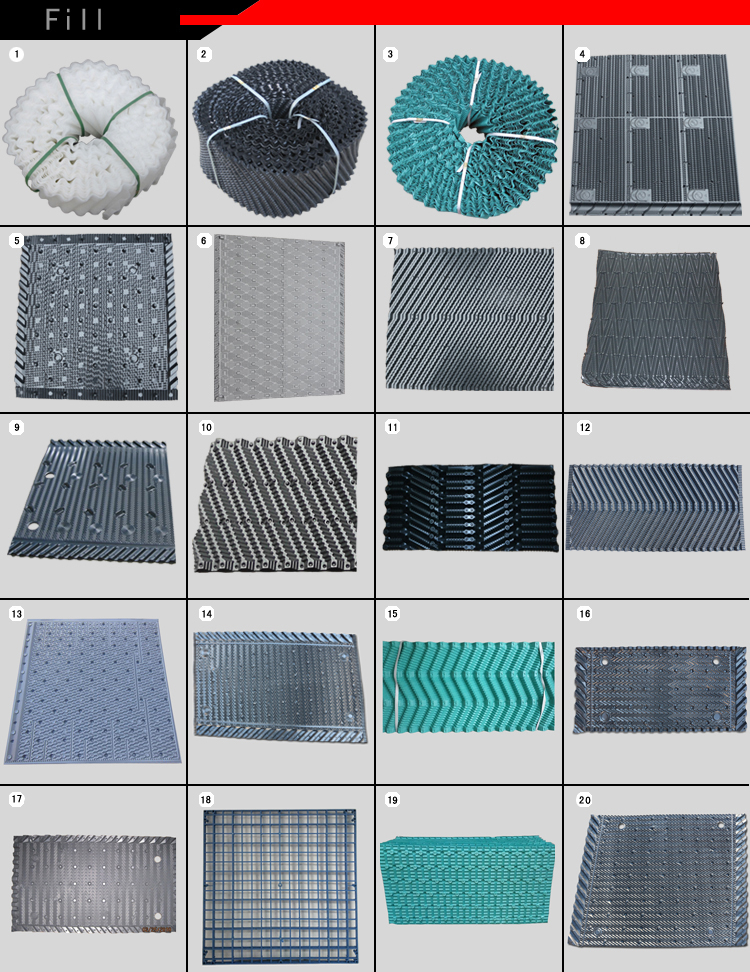

Picture of cooling tower Fill

Advantages of Cooling Tower Fill

1. Improve heat exchange efficiency (core advantage)

Fills provide a large specific surface area, enhancing the contact area between water and air.

Extend the contact time between water flow and air to enhance the formation effect of water film.

It can significantly improve the cooling efficiency of the cooling tower and reduce the outlet water temperature.

Conclusion: Fill is one of the key factors affecting the performance of cooling towers, and high-quality fill can improve cooling efficiency by 10-35%.

2. Reduce water consumption and improve energy-saving performance

Improving heat exchange efficiency means that the same cooling load can use less water and electricity.

Fill can optimize air flow, reduce fan load, and save electricity consumption.

Effect: Some high-performance film fills can save 5-15% energy for fans.

3. Reduce the height and size of the tower (more economical structure)

Because the fill significantly improves heat transfer efficiency, the cooling tower does not require a too high tower body or an excessively long contact distance.

More compact layout and lower civil construction costs.

Results: Under the same cooling capacity, the height of the packed tower can be reduced by 20 – 40% compared with the "unfilled spray tower".

4. Improve water flow characteristics and achieve uniform distribution

Fill can disperse water flow, make the water film flow evenly, and improve cooling stability.

Reduce water flow short circuits, bias currents, or dry spots.

Advantages: It makes the equipment operate more stably for a long time, and the thermal performance is easier to predict and ensure.

Schematic diagram of cooling tower Fill

Why Is Cooling Tower Fill Popular In The German Market

The reason why cooling tower fill is particularly popular in the German market is mainly due to Germany's high emphasis on energy efficiency, environmental protection, and industrial reliability. Germany has strict energy-saving regulations and environmental standards, and various industries have a strong demand for reducing energy consumption, minimizing water replenishment, and improving cooling efficiency. High performance cooling tower fill is a key component for improving heat exchange efficiency, optimizing operating costs, and extending equipment life. In addition, Germany's strong engineering capabilities and high-quality manufacturing standards also drive companies to adopt advanced fill technology more widely to ensure that industrial facilities, data centers, and HVAC systems remain efficient, reliable, and environmentally friendly in long-term operation

TOP 5 Cooling Tower Fill Manufacturers in Germany

1.Power Tower Cooling Technology (Shaoxing) Co.,Ltd

Company Profile:

PT is an excellent domestic manufacturer of cooling tower parts. Since its establishment in 2009, PT has always adhered to the concept of "long-lasting quality and endless innovation".

The company has over 40 product inventions practical technology patents, and has iS09001, 1S014000, and other certifications.

Main products/filler types:

PT produces various cooling tower fills, such as S-wave fills, cross-flow tower fills, counter flow tower fills,round fills. Various brand fills: Liangchi, Lanxun, Spindle, Ebara, Kingsun, etc. Materials include PP, PVC, UPVC.

2.ENEXIO(Enexio Water Technologies / Enexio Management GmbH)

Company Profile:

ENEXIO is a large group brand covering "dry/wet cooling, mixed cooling, and cooling tower components (fill, spray, drip)", with business and manufacturing capabilities in Germany (its subsidiary/affiliated Enexio Water Technologies focuses on water/wastewater and cooling tower components).

Main products/filler types:

film fills, splash/trailer fills, vertical flow fills, drip separators, and complete cooling tower system solutions (including dry/wet/combination).

3.M-CTI - Mumme Cooling Tower International GmbH (Germany)

Company Profile:

M-CTI (Mumme Cooling Tower International) is a German based cooling tower design and manufacturer, specializing in field directed and factory prefabricated cooling towers, as well as providing maintenance, modification, and spare parts (including fill/fill replacement parts). The website shows that its product line covers natural ventilation and mechanical ventilation, as well as various scales of models.

Main products/fill types:

As a complete tower manufacturer, it usually provides or acts as an agent for various types of fill (vertical/cross flow film fill, splash fill), hydraulic distribution systems, sprinkler devices, and internal structural components, and can provide customized fill solutions for large-scale on-site assembly projects.

4.GOHL-KTK GmbH (Germany)

Company Profile:

GOHL-KTK is a German domestic manufacturer of "cooling/re cooling technology", providing engineering design, manufacturing, and after-sales service for cooling towers, re coolers, and complete cooling systems. Its booth information and product specifications are commonly seen in German exhibitions and industry catalogs. The company provides both services and spare parts simultaneously.

Main products/fill types:

Wet cooling tower (open circuit), stainless steel small recooler, modular cooling unit, and matching fill/water distribution and drip separator accessories. Its product line is more inclined towards "system and equipment delivery" rather than large-scale plastic fill mass production.

5.Vereinigte F ü llk ö rper Fabriken GmbH&Co. KG (VFF, Germany)

Company Profile:

VFF (Vereinigte F ü llk ö rper Fabriken) is one of the largest tower fill/random&structured fillmanufacturers in Europe, headquartered in Germany. It has long provided filling materials and column internals, drip separators, and catalytic carriers for the chemical, petrochemical, gas/liquid mass transfer and heat exchange fields. The company emphasizes "100% Made in Germany".

Main products/fill types:

Random fill, structured fill, inert balls/catalyst supports, drip separators (demisters), and related column internals. Its products are widely used in mass transfer conditions such as chemical distillation towers/absorption towers, and can also be adapted to fill scenarios that require high flux/high durability in cooling towers.