Established in 1996 and headquartered in Taipei, Suzhou Liangchi Motor Co., Ltd is aprofessional manufacturer of induction motors. From its inception, Liangchi has abided byits founding values of Mr. Zhang Guangbo-Chairman of Liang Chi lnternational Group,.*motor is the mother of industry.”

Suzhou Liangchi Motor Co., Ltd has a full line of induction motors in both horizontal andvertical configurations, including single-phase capacitor run induction motor, single-phasecapacitor start induction motor, single-phase double capacitor induction motor, three phaselEC standard motor, NEMA motors, three phase inverter motor, etc. The product has 3Cand CSA certification. Liangchi also produce made-to-order motors to cater customer's special needs.To sustain strong and long-term growth, Liangchi focuses particularly on the developmentof advanced technologies and global network of operation. With its overseas branchesexpanding into 16 countries. Liangchi is in a solid position to deliver products more efficientlyand render customer services more effectively.

Hope to establish business relationships with clients from home and abroad, and jointlycreate a bright future.

Liang Chi Cooling Tower Motor Feature

1.Liang Chi Cooling Tower Motor:High efficiency and energy saving

1.Liang Chi Cooling Tower Motor:High efficiency and energy saving

liangchi motor adopts advanced electromagnetic design and high-quality magnetic conductive materials in its design, reducing iron loss and copper loss during motor operation. For instance, its three-phase IEC standard motor, by optimizing the winding design, has increased the efficiency of the motor under rated load by 5% to 10% compared with ordinary motors. In some industrial equipment that operates continuously for a long time, such as the assembly line motors in the food machinery industry, the highly efficient and energy-saving liangchi motors can save a large amount of electricity expenses for enterprises every year and reduce their operating costs.

2.Liang Chi Cooling Tower Motor:Stable and reliable

From material selection to manufacturing processes, liangchi Motor strictly controls every aspect. The motor housing is mostly made of high-strength cast iron. For instance, the high-strength structural design of the housing and the front and rear brackets of the Taiwan liangchi hydraulic motor oil pump dedicated motor can effectively resist external collisions and impacts, protecting the internal precision components. In the selection of key components such as bearings, liangchi Motor adopts imported high-precision bearings, ensuring the accuracy and stability of the motor during operation. In addition, the internal windings of the motor are made of high-grade insulating materials, meeting the F-class insulation and B-class temperature rise standards. It can operate continuously and stably at an ambient temperature of 40℃, greatly extending the service life of the motor and reducing the downtime due to equipment failures.

3.Liang Chi Cooling Tower Motor:Strong environmental adaptability

liangchi Motor fully considers the demands of different industries and working environments. In hot and humid environments, such as cooling towers and other application scenarios, its outdoor moisture-proof and sealed motor has excellent moisture resistance. The motor windings have undergone special impregnation treatment, which not only can resist the erosion of moist air but also can withstand a certain degree of environmental pollution, ensuring efficient and low-noise operation in harsh outdoor environments. For some special environments with potential explosion risks, liangchi Motor has also launched three-phase explosion-proof motors to meet the strict requirements of industries such as chemical engineering and coal mining, providing safe and reliable power support for the operation of equipment in special environments.

4.Liang Chi Cooling Tower Motor:Low-noise operation

During operation, the noise control performance of liangchi motor is excellent. Take the cooling tower motor as an example. By optimizing the design of the fan blades, streamlined aluminum alloy blades are adopted, and they undergo strict dynamic and static balance tests before leaving the factory, ensuring the stability of the fan during operation and significantly reducing the noise caused by fan vibration. Meanwhile, the internal structure design of the motor also fully takes into account the noise reduction requirements. The bearings, rotors and other components of the motor have been optimized to reduce the friction and collision noise between the components. The use of liangchi motors in the equipment around noise-sensitive places such as hospitals and schools can effectively prevent noise from interfering with the environment and create a quiet and comfortable living and working environment for people.

5.Liang Chi Cooling Tower Motor:Convenient for installation and maintenance

During the design stage, liangchi Motor took into account the convenience of installation and maintenance. Most of its motor products adopt standardized IEC dimensions, and there is good interchangeability among different models. When upgrading the equipment or replacing the motor, there is no need for large-scale structural modifications to the equipment, and the installation process is simple and fast. The junction box, made of large-sized cast iron, provides a spacious area for wiring operations, facilitating the connection and maintenance of the lines by the staff. In addition, the motor is equipped with a complete set of protection devices, such as a coil temperature protection device and a thermal protector. When abnormal conditions occur in the motor, it can promptly issue an alarm and take protective measures, facilitating the staff to quickly locate and solve the problem, and reducing the difficulty and cost of maintenance.

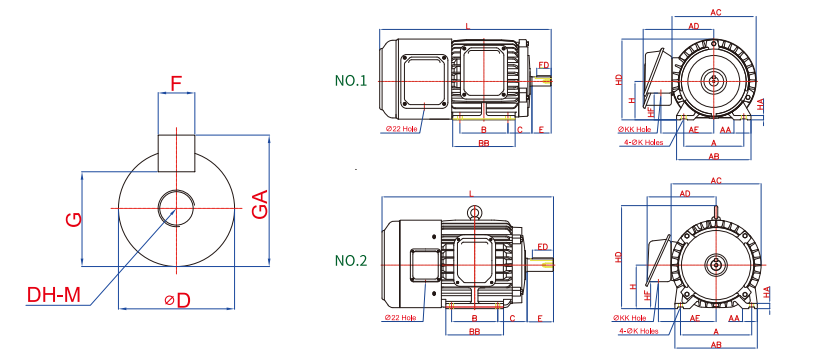

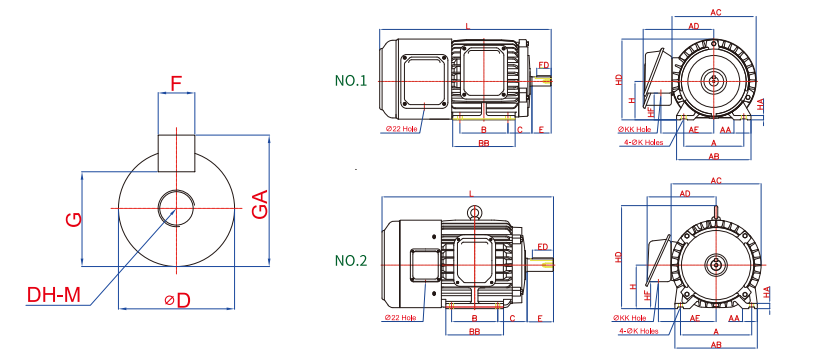

Liang Chi Cooling Tower Motor Parameter

| FRAME | NO | OUTPUT(HP) | INS | L | ΦM | ΦN | ΦP | ΦS | T | ΦAC | AE |

| 2P | 4P | 6P |

| 71M | 2 | 1/2 | 1/2 | 1/4 | 7 | 340 | 130 | 110 | 160 | 10 | 3.5 | 161.5 | 103 |

| 80M | 1 | 1 | 1 | 1/2 | 357 | 165 | 130 | 200 | 12 | 176.5 | 112 |

| 90L | 2 | 2,3 | 2 | 1 | 440 | 196.5 | 125 |

| 100L | 1 | - | 3 | 2 | 465 | 215 | 180 | 250 | 14.5 | 4 | 224 | 147 |

| 112M | 2 | 5 | 5 | 3 | 512 | 234 | 154 |

| 132S | 1 | 7.5,10 | 7.5 | 5 | 520 | 265 | 230 | 300 | 273 | 181.5 |

| 132M | - | 10 | 7.5 | 558 |

| 160M | 2 | 15,20 | 15 | 10 | 700 | 300 | 250 | 350 | 18.5 | 5 | 334 | 220 |

| 160L | 25 | 20 | 15 | 744 |

| 180M | 30 | - | - | 784 | 350 | 300 | 400 | 382 | 245 |

| - | 25,30 | 20 |

| 180L | 40 | - | - | 822 |

| - | 40 | 25,30 |

| 200L | 3 | 50,60 | - | - | 863 | 400 | 350 | 450 | 420 | 290 |

| - | 50,60 | 40,50 | 893 |

| 225S | 75 | - | - | 884 | 500 | 450 | 550 | 458 | 307 |

| - | 75 | 60 | 914 |

| 250S | 4 | 100 | - | - | 990.5 | 510 | 366 |

| - | 100 | 75 | 1020.5 |

| 250M | 125 | - | - | 1047.5 |

| - | 125 | 100 | 1077.5 |

Liang Chi Cooling Tower Motor Performance

Ambient Temperature:-15℃~40℃

Horse Power: 1/2HP~125HP

Poles:2P、4P、6P

Altitude: below 1000m

Voltage: 200v,220v,380V,400V, 440V,460V,480V

Frequency: 50 or 60HZ

Continuous Duty(S1),SF1.0

Insulation: Class F

Protection Enclosure: P54

Thermal Protection: Mz6 PTC

Optional Accessory: Encoder

Low Noise, Exchangable Installation Size. Totally Enclosed Design

Liang Chi Cooling Tower Motor Application

As the core power component of cooling tower equipment, Liangchi cooling tower motors play a crucial role in the cooling systems of multiple fields such as industrial production, commercial buildings, and public facilities. With their adaptability and stability, they have become an important guarantee for the efficient operation of cooling towers.

1.LiangChi Cooling Tower Motor Application:In industrial manufacturing

In industrial manufacturing scenarios, Liangchi cooling tower motors are widely used in various types of industrial cooling towers.

Liang Chi Cooling Tower Motor in Steel plant

The high-temperature steel rolling process in steel plants generates a large amount of waste heat. The cooling tower needs to continuously cool down the equipment. The motor drives the fan to rotate at high speed, accelerating the heat exchange between the cooling water and the air to ensure that key equipment such as the rolling mill operates at an appropriate temperature.

Liang Chi Cooling Tower Motor in The Chemical plant

The heat released by equipment such as reaction vessels and distillation towers in chemical plants during the production process needs to be dissipated in a timely manner. Liangchi cooling tower motors, with their excellent dust-proof and water-proof performance, can work stably in environments with a lot of dust and corrosive gases, ensuring the continuous operation of the cooling system and avoiding production stagnation due to equipment overheating.

2. Liang Chi Cooling Tower Motor:In commercial and public building

Liang Chi Cooling Tower Motor in The commercial and public

The commercial and public building sectors also cannot do without Liangchi cooling tower motors.

Liang Chi Cooling Tower Motor in Shopping mall and hotel

When the central air conditioning systems of large shopping malls and hotels are cooling in summer, the cooling towers play a crucial role in heat dissipation. The motors drive the fans to release the heat generated by the air conditioning system into the air. Its feature of low-noise operation avoids disturbing customers in shopping malls and hotels, creating a quiet and comfortable environment.

Liang Chi Cooling Tower Motor in Hospital

The central air conditioning and cooling systems of various medical equipment in hospitals have extremely high requirements for stability. The reliable performance of Liangchi cooling tower motors ensures the continuous operation of the cooling system, providing a stable temperature environment for operating rooms and precision medical instruments, and guaranteeing the smooth progress of medical work.

3.LiangChi Cooling Tower Motor:In the energy and power industry

Liang Chi Cooling Tower Motor in Thermal power plant

In the energy and power industry, Liangchi cooling tower motors are applied to cooling towers in power plants. When the steam turbines and generators in a thermal power plant are in operation, they generate a large amount of heat. The cooling tower needs to quickly remove this heat. The motor drives the fan to work efficiently, helping the power generation equipment maintain a normal operating temperature and ensuring a stable power output.

Liang Chi Cooling Tower Motor in a nuclear power plant

The auxiliary cooling system of a nuclear power plant has strict requirements for the safety and reliability of the equipment. The excellent performance of Liangchi cooling tower motors meets these high standards and provides strong support for the safe operation of the nuclear power plant.

4.Liang Chi Cooling Tower Motor:Another application

Liang Chi Cooling Tower Motor in data centers

In addition, in places such as data centers where extremely high cooling efficiency is required, Liangchi cooling tower motors also play a significant role. When the server cluster in a data center is in operation, it generates a huge amount of heat. The cooling tower needs to dissipate heat efficiently to maintain the normal operation of the servers. The motor precisely adjusts the speed to match the heat dissipation requirements under different loads, ensuring the cooling effect while achieving energy conservation and helping the data center reduce operating costs.

Liang Chi Cooling Tower Shipment

Packing:

Wooden,cartons,custom package.

Delivery time:

Within 10 days.

Our Services of LiangChi Cooling Tower Motor

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.