Introduction To Counterflow Cooling Tower Nozzles

Views: 0 Author: Lisa Publish Time: 2025-12-02 Origin: Site

Here’s a clear and complete guide to counterflow cooling tower nozzles—types, sizing, flow rates, and recommended manufacturers.

✅ 1. What Nozzles Are Used in Counterflow Cooling Towers?

Counterflow towers use pressurized spray nozzles mounted on a sprinkler pipe grid above the fill.

Their job: create uniform water distribution over the fill pack.

Most common counterflow nozzle types:

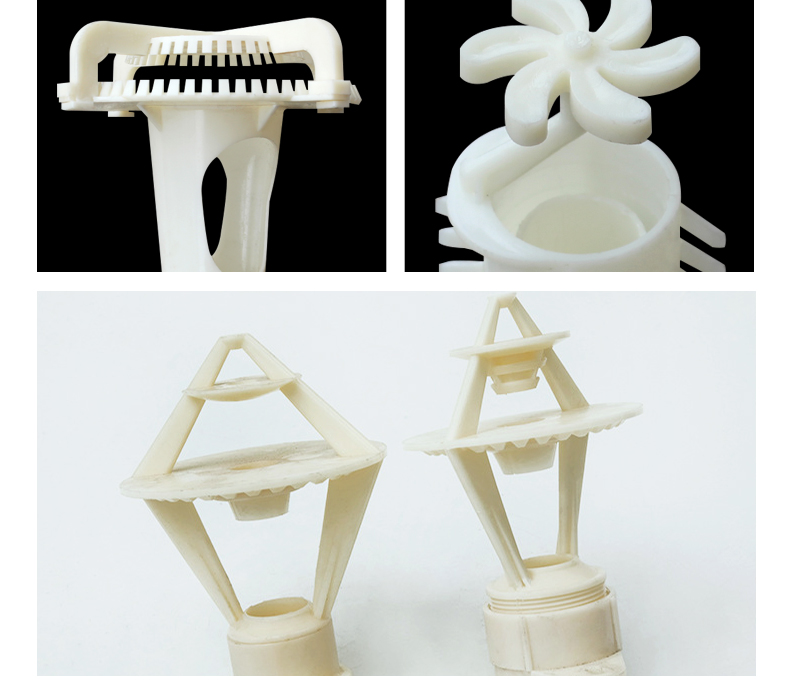

A. ABS / PP Spiral Spray Nozzles (Most common)

* 2–20 m³/h typical flow

* Threaded or push-fit connection

* 360° spray pattern

* Clog-resistant

Used in:

* Medium & small counterflow towers

* Many Chinese OEM towers, as well as Marley equivalents

B. Target Nozzles / “Flower Type” Nozzles**

* Water hits a target plate and spreads into a uniform cone

* Works even at low pressure

* Easy to clean

Good for:

* Light industrial towers

* Replacements for Marley & Liangchi towers

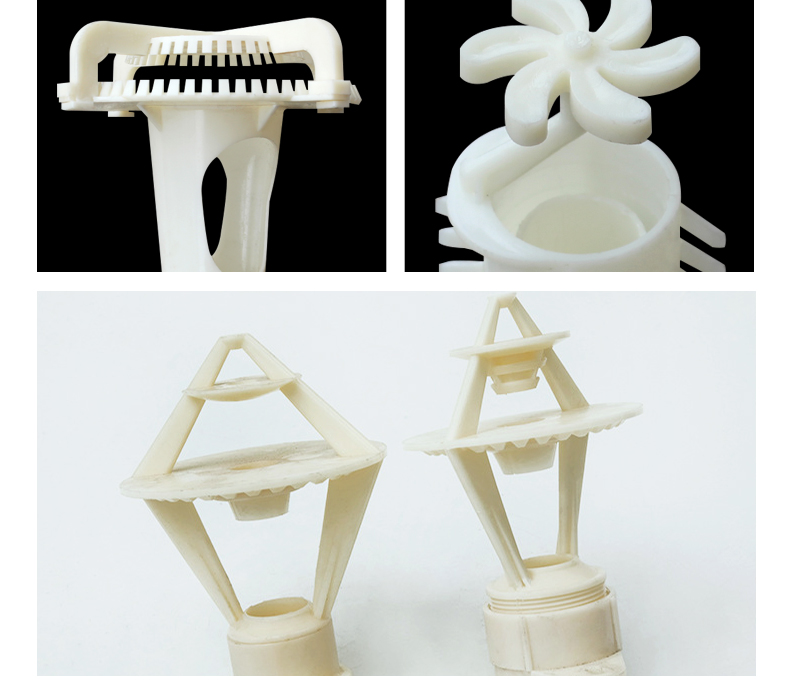

C. Long-Neck Counterflow Spray Nozzles

* Extended neck keeps the nozzle at the correct height above fill

* Prevents channeling

* Uses ABS/PP body with snap-on orifice caps

Used in:

* Larger industrial counterflow towers

* Deep fill sections

D. Pipe-Connected High-Flow Spray Nozzles

(Used in large power-plant or chemical towers)

Features:

* 10–50 m³/h flow

* High-uniformity fogged spray

* Stainless steel or CPVC construction

✅ 2. Typical Flow Rates & Pressures

| Nozzle Type | Typical Flow | Pressure |

| ABS Spiral | 2–20 m³/h | 0.5–1.5 bar |

| Target Nozzle | 3–12 m³/h | 0.3–1.0 bar |

| Long-Neck Nozzle | 5–25 m³/h | 0.5–1.2 bar |

| Industrial SS Nozzle | 10–60 m³/h | 1.0–3.0 bar |

Uniform water distribution is critical because counterflow towers depend on pressure-fed spray.

✅ 3. Best Manufacturers of Counterflow Cooling Tower Nozzles

Global

* SPX Marley – Spiral & target nozzles

* BAC – High-performance pressurized spray systems

* Evapco – ABS and polymer nozzles

China

Excellent for replacement parts or OEM supply:

| Manufacturer | Notable Nozzles |

| Liangchi (良机) | ABS spiral, long-neck, Marley-style |

| Newin (纽恩) | Target + spiral nozzles |

| Shandong Broad | Spiral nozzles (OEM replacements) |

| King Sun | Small & medium ABS nozzles |

| Power Tower Cooling Technology (Shaoxing) Co.,Ltd | Large-flow PP nozzles, Kinds of ABS nozzles |

✅ 4. How to Choose the Right Counterflow Nozzle

To select the correct type, I need:

1. Tower brand/model (e.g., Marley NC, Liangchi LX, Newin NCT)

2. Pipe size (DN25 / DN32 / DN40 etc.)

3. Flow per nozzle (m³/h or GPM)

4. Spray angle (typically 120°–180° for counterflow)

5. Material needed (ABS, PP, PVC, CPVC, brass)