Cooling towers play a crucial role in maintaining the efficiency of industrial and commercial systems by dissipating heat. Like any piece of equipment, cooling towers require regular maintenance and, at times, parts replacement to keep functioning at optimal levels. Whether you're responsible for managing a cooling tower or you're simply curious about how these systems work, understanding when and how to replace cooling tower parts is essential.

In this guide, we'll walk you through the common parts that need replacement, signs to look out for, and a detailed, step-by-step approach for the replacement process. By the end, you'll be equipped to keep your cooling tower running smoothly and efficiently.

Introduction to Cooling Towers

What Is a Cooling Tower?

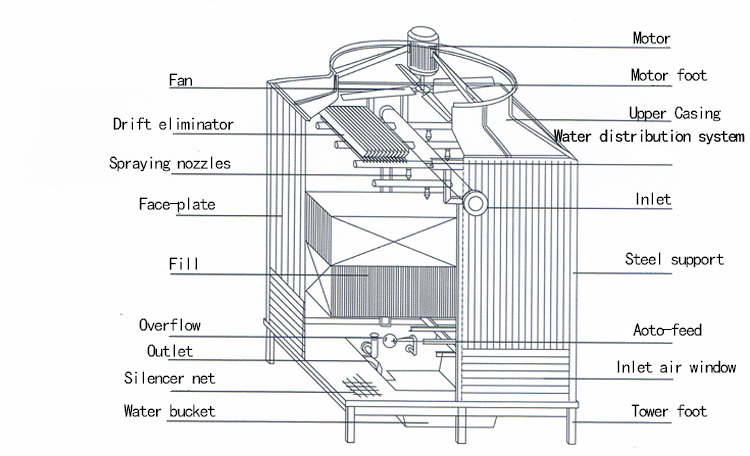

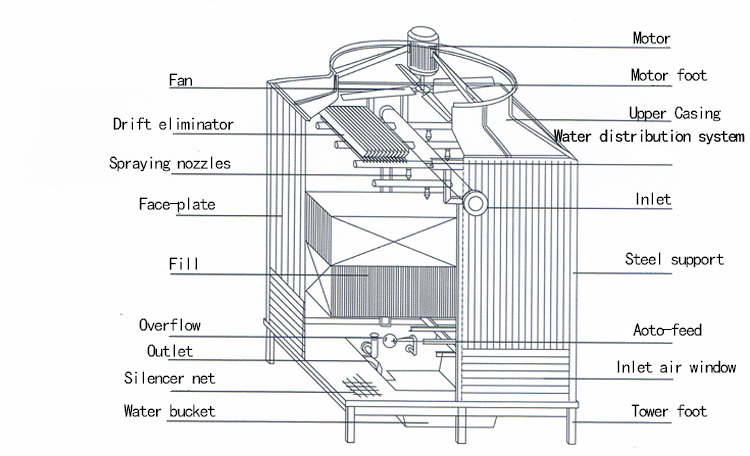

A cooling tower is a heat rejection device that expels unwanted heat to the atmosphere through evaporative cooling. It's used in industries ranging from power plants and HVAC systems to chemical manufacturing and refineries. Essentially, a cooling tower helps remove heat from water that has absorbed heat from industrial processes or air conditioning systems.

These towers typically come in two main designs: wet and dry. In wet cooling towers, water is exposed to air to cool it, while in dry towers, air is blown over heated surfaces to cool them.

Why Regular Maintenance and Replacement Are Important

Cooling towers are vital for maintaining the efficiency of numerous industrial processes, so proper maintenance and timely replacement of parts are crucial. Neglecting this can result in costly downtime, increased energy usage, and even catastrophic system failure. Regular part replacement ensures that your cooling tower continues to operate at peak performance while minimizing risks.

Common Cooling Tower Parts That Need Replacement

As a cooling tower ages, certain components will naturally wear out or degrade. Understanding which parts need replacement—and when—is vital to prolonging the life of your system.

Fans and Motors

The fan and motor are two of the most important parts of a cooling tower. They are responsible for circulating air through the system. If the fan becomes damaged, or if the motor fails, the cooling tower will lose its ability to properly dissipate heat. Over time, the bearings can wear out, or the motor may show signs of electrical issues. When that happens, it's time to replace these components to ensure efficient operation.

Fill Media

Fill media inside the cooling tower helps increase the surface area where water can be cooled. As fill media degrades due to mineral buildup or physical wear, its efficiency decreases, leading to less effective heat dissipation. If you notice a decline in cooling performance, it may be time to inspect and replace the fill media.

Drift Eliminators

Drift eliminators are designed to capture water droplets that would otherwise escape into the atmosphere. Over time, these parts can become clogged, damaged, or warped, causing water loss and reduced efficiency. When they no longer perform their function properly, replacing them is a necessity.

Nozzles and Spray Systems

The nozzles in a cooling tower are responsible for distributing water evenly over the fill media. If these nozzles become clogged or damaged, the water distribution becomes uneven, affecting the system's cooling efficiency. A quick replacement of damaged or worn-out nozzles can significantly improve the performance of your cooling tower.

Basins and Sumps

Basins and sumps collect and store the water that circulates through the system. Over time, these parts may suffer from corrosion, scaling, or structural damage. Keeping your basins in top condition is important to prevent leaks or water contamination.

Signs That Indicate It's Time for Replacement

Knowing when to replace a part is just as important as knowing what to replace. Here are some key signs that can help you determine when your cooling tower components need attention:

Decreased Efficiency and Performance

If your cooling tower is not providing the same level of cooling it once did, or if the system is requiring more energy to achieve the same results, it may be time to replace one or more of its components. Efficiency drops are often caused by degraded parts, such as worn-out fans or clogged fill media.

Unusual Noises and Vibration

If you hear unusual noises such as grinding or screeching, or if you notice excessive vibration in the cooling tower, it could indicate that something is wrong with the fan, motor, or other mechanical parts. These noises can be a sign of damage or wear that requires immediate replacement.

Visible Wear and Corrosion

Corrosion is a common issue in cooling towers, especially in areas where water quality is poor. If you spot rust, cracks, or other visible signs of wear, it's a clear indicator that replacement is necessary to maintain the tower's efficiency and integrity.

Step-by-Step Guide for Replacing Cooling Tower Parts

Replacing parts in a cooling tower can seem like a daunting task, but with the right approach and preparation, it can be done efficiently and safely. Here's a step-by-step guide to help you through the process.

Step 1: Shut Down and Isolate the System

Before beginning any work on the cooling tower, it's crucial to shut down the system and isolate it from the power source. This ensures that you can work safely without risking injury or further damage to the system.

Step 2: Identify the Problematic Parts

Once the system is shut down, conduct a thorough inspection to determine which parts are damaged or worn out. Use diagnostic tools, if available, to pinpoint the exact issue.

Step 3: Gather the Right Tools and Parts

Before starting the replacement process, make sure you have all the necessary tools, such as wrenches, screwdrivers, and safety equipment. You’ll also need replacement parts—fans, motors, nozzles, etc.—which should be purchased from reliable suppliers.

Step 4: Disassemble and Remove the Old Parts

Carefully remove the damaged parts. For example, when replacing a fan, you’ll need to remove the fan blades, motor, and any surrounding components that could be obstructing access.

Step 5: Install the New Parts

Once the old parts are removed, install the new ones. Ensure that everything is correctly aligned and securely fastened to avoid any issues during operation. For instance, when installing a new fan motor, make sure the bearings are lubricated and the wiring is intact.

Step 6: Test the System and Ensure Proper Functioning

After all the parts are replaced, power up the system and test it for functionality. Check for any unusual sounds or vibrations and verify that the cooling tower is performing as expected.

Best Practices for Maintaining Cooling Tower Parts

To prevent frequent replacements and ensure your cooling tower runs smoothly, follow these best practices for maintenance:

Regular Inspections

Schedule regular inspections to check for signs of wear and tear on critical components. Early detection of issues can prevent expensive repairs later.

Cleaning and Lubrication

Regular cleaning of parts such as fans and nozzles helps prevent buildup and corrosion. Lubricating moving parts can also extend their life.

Monitoring System Performance

Regularly monitor the performance of the system to detect any drop in efficiency or other issues. This can help identify the need for parts replacement before it becomes a major problem.

Conclusion: Why Timely Replacement Is Key

Save on Long-Term Costs

While replacing parts might seem costly in the short term, it can actually save you money by preventing more serious damage and reducing energy consumption in the long run.

Ensure Operational Safety and Efficiency

By replacing worn-out parts promptly, you help ensure the safety, efficiency, and longevity of your cooling tower. Regular maintenance is key to keeping operations running smoothly without unnecessary downtime or costly repairs.