Cooling Tower Fill Media Replacement Parts: A Complete Guide

What is Cooling Tower Fill Media?

When you think of a cooling tower, one of the most important components that often gets overlooked is the fill medie. Fill media is a specially designed material used inside the cooling tower to maximize the surface area for heat transfer between water and air. Essentially, it increases the contact time for water to exchange heat, making the cooling process much more efficient.

The Function of Fill Media in Cooling Towers

The purpose of fill media is simple: to enhance heat exchange. As water flows over or through the fill material, air is blown across it, and heat is transferred from the water to the air, usually by evaporation. The larger the surface area that the water is spread over, the better the heat transfer. This process allows the cooling tower to reduce the temperature of the water before it is recirculated back into the system. So, without fill media, cooling towers wouldn’t be able to function efficiently.

Why Do Cooling Tower Fill Media Need Replacing?

Like all components of a cooling tower, fill media wears down over time due to constant exposure to water, air, and environmental elements. Regular replacement is necessary to ensure the cooling tower maintains its efficiency.

Common Issues with Fill Media

Over time, cooling tower fill media can suffer from several common issues, including:

1. Fouling: The accumulation of dirt, debris, and biological growth can block the surface of the fill media, reducing its efficiency.

2. Corrosion: Exposure to chemicals and harsh weather conditions can cause fill media to deteriorate.

3. Physical Damage: The fill material can crack or break due to physical stress, reducing the surface area available for heat exchange.

Signs Your Fill Media Needs Replacement

So, how do you know it’s time to replace your fill media? Here are a few key signs:

* Reduced Cooling Efficiency: If the tower is no longer cooling the water to the desired temperature, your fill media might be clogged or worn out.

* Waterflow Issues: If water isn’t flowing smoothly over the fill or is accumulating in certain areas, it might be a sign of blockages or damage.

* Visible Damage: Cracks, splits, or signs of corrosion on the fill media surface are clear indications that replacement is necessary.

Choosing the Right Fill Media Replacement Parts

When it’s time to replace the fill media, choosing the right replacement parts is essential to keeping your cooling tower functioning at its best.

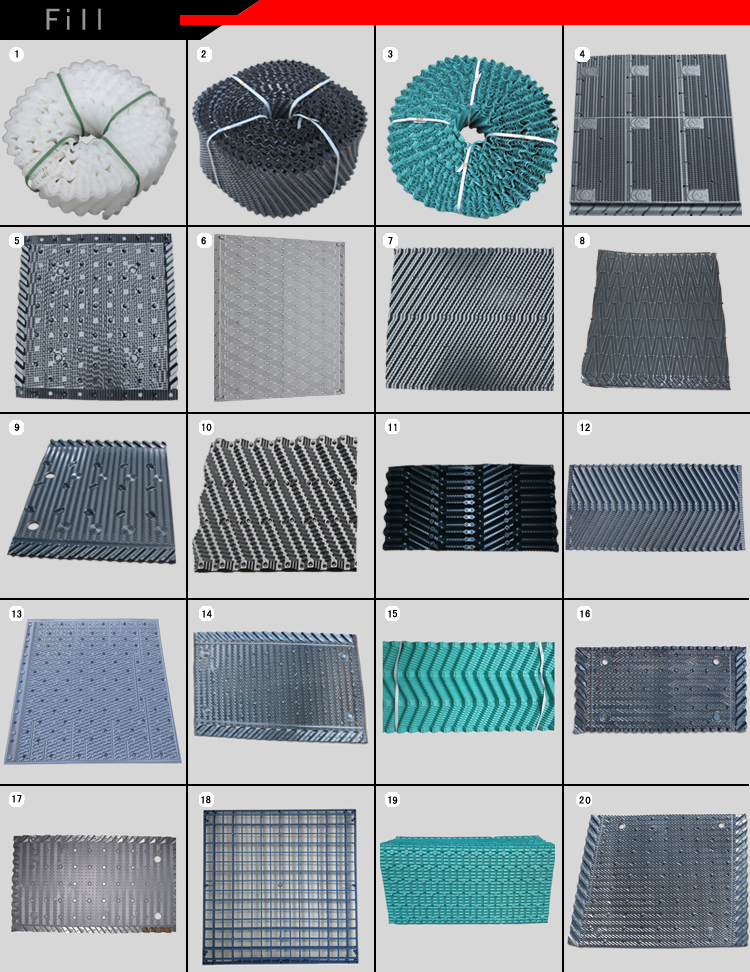

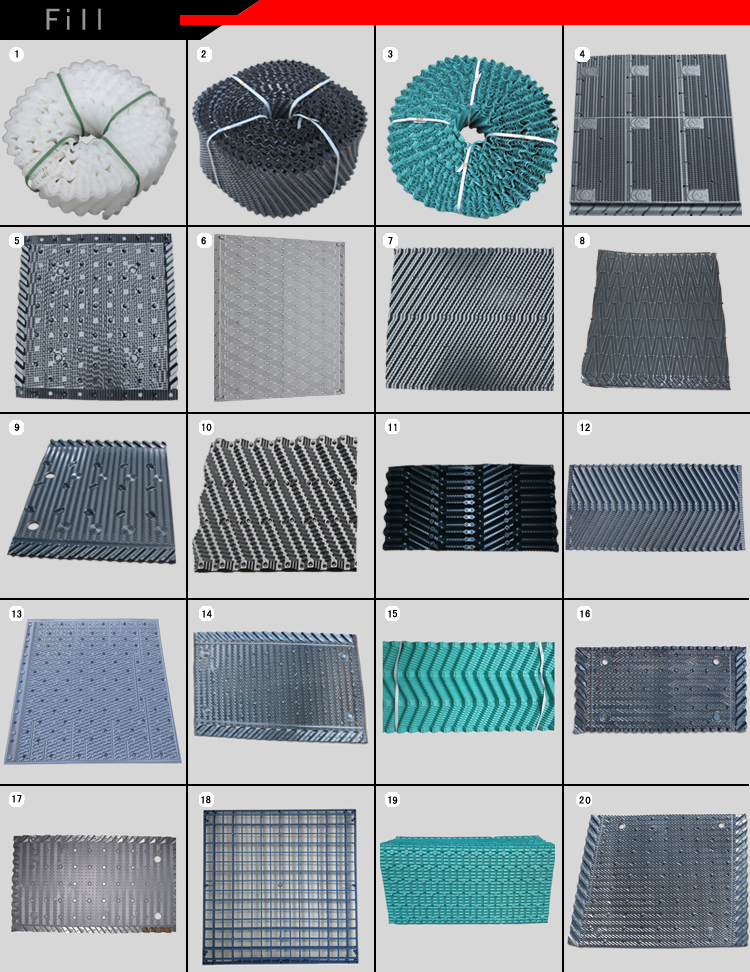

Types of Fill Media Materials

Cooling tower fill media comes in various materials, each offering different benefits depending on the specific needs of your system.

* PVC (Polyvinyl Chloride): This is the most common material for cooling tower fill. It’s resistant to corrosion, lightweight, and durable.

* Polypropylene: Similar to PVC but more resistant to higher temperatures, making it a good choice for certain industrial applications.

* Stainless Steel: In very specific circumstances, stainless steel may be used for fill media, especially in high-corrosion environments.

Size and Configuration Considerations

When replacing fill media, size matters. Be sure that the replacement media is the same size and configuration as the original. Otherwise, water distribution and cooling efficiency could be compromised.

Structured vs. Random Fill Media

* Structured Fill: This type of fill media is designed with a specific geometric structure that maximizes surface area for heat exchange. It’s typically more efficient than random fill and can handle higher water loads.

* Random Fill: Made of pieces that are randomly placed inside the cooling tower, this type of media is less efficient but often cheaper.

Structured fill is ideal for most systems as it tends to last longer and provides better heat exchange performance.

The Process of Replacing Cooling Tower Fill Media

Replacing cooling tower fill media is a task that requires proper planning and execution. Here’s how you can do it.

Step-by-Step Guide to Replacing Fill Media

1. Shut Down the System: Before doing any work, always ensure the cooling tower is turned off to avoid any accidents.

2. Remove the Old Fill Media: Carefully remove the old fill media, either by dismantling the tower sections or pulling the media out directly, depending on your system.

3. Clean the Tower: Clean the interior of the cooling tower to remove any dirt, debris, or biological buildup that may have accumulated. This helps prevent future fouling.

4. Install the New Fill Media: Carefully place the new fill media in the appropriate locations inside the cooling tower, ensuring it is aligned correctly.

5. Test the System: After installation, start the cooling tower and monitor the system. Check for proper water distribution and airflow to ensure the new media is working effectively.

Tools and Safety Tips for Replacement

You’ll need the following tools to replace fill media:

* Ladders or lifts for accessing high areas

* Safety gloves and goggles for protection

* Screwdrivers and wrenches to remove old components

* Measuring tape for precise sizing

Be sure to wear appropriate personal protective equipment (PPE) and follow all safety guidelines while working in or around a cooling tower.

Removing Old Fill Media

Removing the old fill media involves carefully disassembling the sections that house the media. Use the proper tools to avoid damaging the tower or surrounding components. If the media is stuck due to mineral buildup, a soft-bristled brush or mild cleaner can be used to loosen the debris.

Installing the New Fill Media

Place the new fill media carefully in the correct configuration. Structured fill should be placed according to the manufacturer’s specifications to maximize surface area and improve heat transfer. Make sure everything is aligned properly to prevent uneven water distribution.

Benefits of Replacing Cooling Tower Fill Media

Replacing aging fill media brings several significant benefits to your cooling tower and overall system performance.

Improved Heat Transfer Efficiency

New fill media increases the available surface area for heat exchange, which improves the overall cooling efficiency of the system. This means that your cooling tower will be able to cool the water more effectively, lowering energy costs and maintaining optimal performance.

Reduced Water Loss and Energy Costs

When your cooling tower is operating efficiently, less water will be wasted due to inefficient evaporation. Additionally, the improved heat transfer reduces the load on compressors and fans, saving energy in the long run.

Troubleshooting Fill Media Problems

Even with the best replacement parts, issues can arise with fill media. Here are a few common problems and how to troubleshoot them.

Clogging and Fouling

Clogging occurs when debris, dirt, or biological growth block the surfaces of the fill media, reducing efficiency. Regular cleaning and maintenance can help reduce this. You can also use anti-fouling agents to prevent buildup.

Fill Media Wear and Tear

Over time, fill media can crack or break down due to prolonged exposure to harsh chemicals or high temperatures. When this happens, replace the damaged sections promptly to prevent further damage to the system.

Conclusion: Why Timely Fill Media Replacement is Crucial

Maintaining and replacing cooling tower fill media at the right intervals ensures that your cooling tower operates efficiently, saving water, energy, and money. Don’t wait until problems become severe—schedule regular inspections and replacements to keep your system running smoothly.

Regular Maintenance for Longevity and Performance

By staying on top of fill media replacement and regular maintenance, you ensure that your cooling tower continues to perform at its best for years to come. A little investment in maintenance now can save you a lot in future repairs and energy costs.

This detailed guide on cooling tower fill media replacement parts covers everything from the importance of the media to how to replace it properly. Keep your cooling tower in top condition, and you'll reap the benefits of improved performance and reduced operating costs.