ABB motors are of the totally enclosed, three phase squirrel cage type, built to comply with international IEC and China GB standards. The efficiency level reaches GB Grade 1 (GB18613-2020),the efficiency level is equivalent to IEC IE5. Production units are certified to ISO 9001 international quality standard as well as ISO 14000 environmental standards.

M2BAF series motors are mainly tailored for fans, pumps, extruder, mixer, cable machinery and food machinery OEM customers, it is suitable for water treatment, HVAC, F&B and many other industries. The excellent quality and service of M2BAF provide customers with value-added space and ensures the fast delivery of orders.

ABB Cooling Tower Motor Feature

1.ABB Cooling Tower Motor :High efficiency and energy saving

It is often used in conjunction with frequency converters, such as the ACS880 frequency converter, which can adjust the motor speed according to the actual working conditions, enabling the fan to operate as needed and achieving energy conservation. The frequency converter can smoothly accelerate or decelerate the fan, avoiding the current peak and stress caused by full-voltage start-up. Compared with traditional control methods, the average power-saving rate can reach 20% to 50%, and in extreme scenarios, it can even reach 90%.

2. ABB Cooling Tower Motor:High reliability

By adopting direct drive technology, it replaces the gearboxes, drive shafts and other components typically used in industrial cooling fans, reducing the number of components and thus the risks brought about by their failures, as well as lowering maintenance workload and costs. Meanwhile, the motor bearings have a long service life. The service life of L10 exceeds 100,000 hours, which can ensure the long-term stable operation of the equipment.

3.ABB Cooling Tower Motor: Strong protective performance

Specially designed for outdoor use, it can withstand 100% humidity and extreme chemical environments. Motors with frame sizes FL44XX and FL58XX prevent water from entering along the shaft through sealing rings on the shaft. Motors with smaller frame sizes prevent water from entering along the shaft through V-rings and have a trickle current function to keep the motor warm and dry and prevent condensation.

4. ABB Cooling Tower Motor:Low noise operation

By optimizing the electromagnetic and electrical design, cooling system and structure, ABB cooling tower motors can minimize noise to the lowest extent. The motor can also be placed inside the air outlet duct or at the upper part of the tower cavity to prevent the noise from spreading outside the tower, further meeting the requirements of scenarios with higher noise demands.

5. ABB Cooling Tower Motor:Flexible and convenient installation

It offers foot or flange installation designs. The shaft height, diameter and flange installation dimensions can be directly interchangeable with some existing cooling tower gearbox designs. There are multiple bolts distributed at the non-driven end of the motor, which is convenient for replacement and installation. The FL58XX frame size motor is standard with shock-absorbing pads, and smaller frame size motors are optional, which can reduce the impact of vibration on installation.

6. ABB Cooling Tower Motor:Rich control functions

Supports sensorless permanent magnet motor control, eliminating the need for built-in encoders or resolvers, thereby reducing costs and complexity. It also has an internal de-icing function to keep the fan blades ready for operation and prevent them from rotating when the fan is not in use, thus adapting to various operating conditions.

7. ABB Cooling Tower Motor:Excellent insulation performance

It adopts an F-class insulation system and is tested in accordance with B-class insulation standards, which enhances the reliability of motor operation, extends the motor's service life, and can withstand high temperatures and electrical stress to a certain extent.

ABB Cooling Tower Motor General Feature

| General Feature |

| Insulation | F |

| Degrees of protection | IP55 |

| Cooling | IC411 |

| Voltage | 380V |

| Frequency | 50Hz |

| Y connection for 3kw and below,Δ connection for 3kW above |

| Ambient temperature | -20℃~40℃ |

| Max altitude | 1000m |

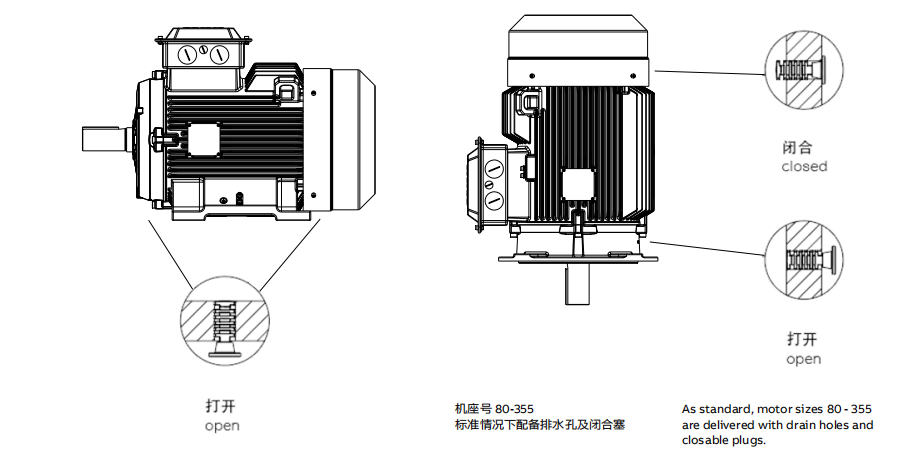

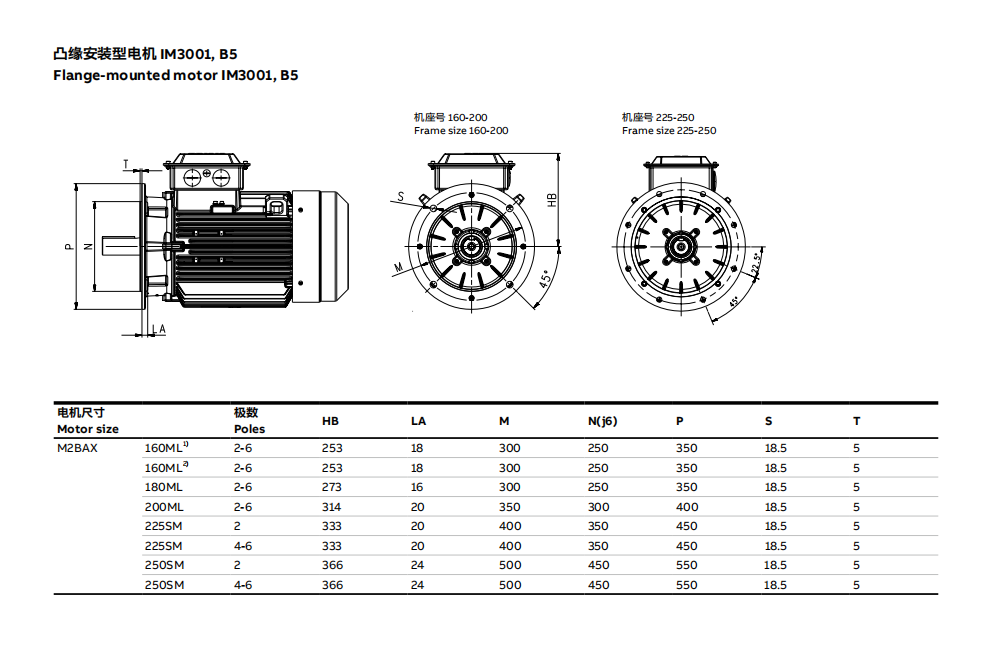

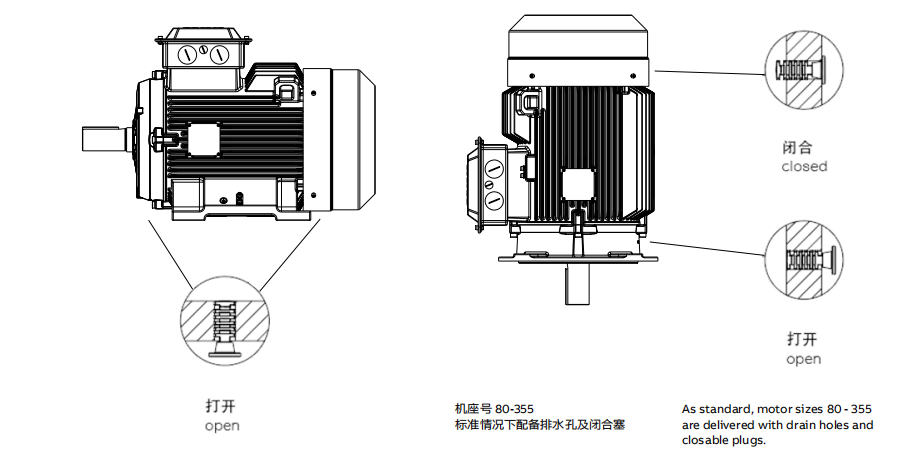

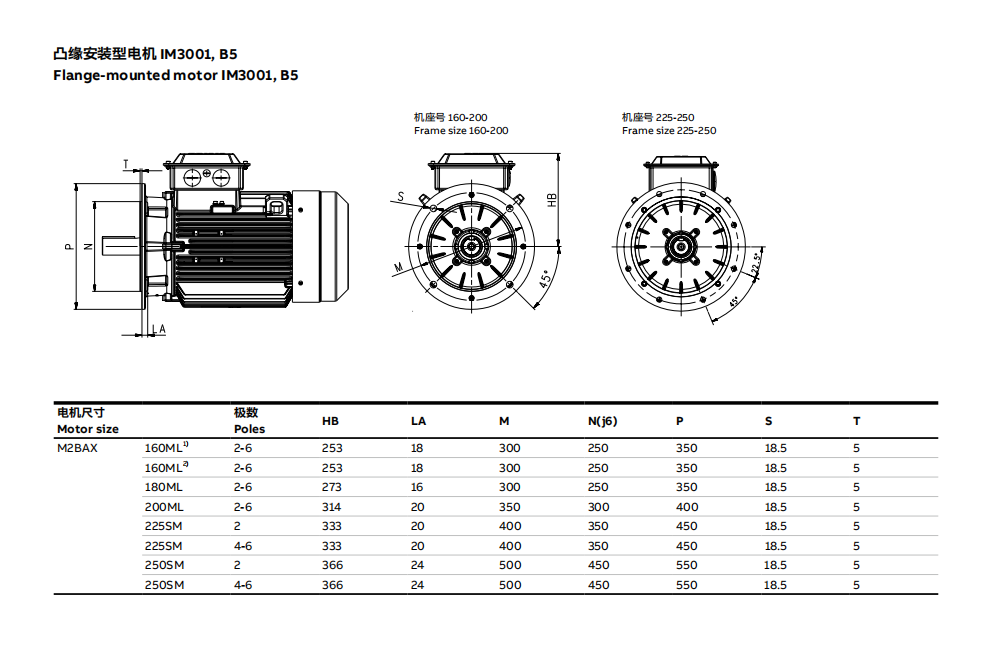

ABB Cooling Tower Motor Dimension drawings

ABB Cooling Tower Motor Application

1.ABB Cooling Tower Motor Application in Metallurgical industry:

Covering the entire process links of the upstream and downstream of metallurgy. For instance, in the hot rolling and cold rolling processes, the roller motors of ABB have the highest IP66 level of protection, which can resist dust and other substances. The special shaft seal design can cope with harsh environments, and the 20-year ultra-long service life reduces the frequency of maintenance. The M2QA high-efficiency motor can be used in the fluid system of metallurgical auxiliary processes, while the ABB AMI modular induction motor can be applied in key processes such as upstream pelletizing, midstream DRI and downstream steelmaking in hydrogen metallurgy.

2. ABB Cooling Tower Motor in Food and Beverage industry:

Provide power for food and beverage production equipment, such as mixers, filling machines, conveyor belts, etc. ABB has launched a first-level ultra-high-efficiency (IE5) motor for this industry, helping enterprises reduce energy consumption and production costs, and meeting the requirements of the food and beverage industry for efficient, hygienic and reliable equipment.

3. ABB Cooling Tower Motor in Chemical Industry:

The QABP series variable frequency speed regulation three-phase asynchronous motor can be used as an ideal speed regulation power source in the chemical industry. It can achieve stepless speed regulation within the range of 5-100Hz and withstand an overload of 160% of the rated torque. Its F-class insulation and IP55 protection grade enable it to adapt to the relatively complex working conditions in the chemical industry.

4.ABB Cooling Tower Motor in Water treatment industry:

It is often used in equipment such as water pumps to provide power for water transportation and treatment. The high-efficiency and energy-saving features of ABB motors help reduce the power consumption in the water treatment process. Their reliable performance can ensure the stable operation of the water treatment system and reduce the downtime for maintenance.

5. ABB Cooling Tower Motor in Shipbuilding industry:

It provides power support for the propulsion system, deck machinery, cabin ventilation, etc. of ships. Its motor products can meet the operational requirements of ships in harsh Marine environments and have excellent moisture-proof and salt fog-proof performance, ensuring the reliable operation of the ship's power system.

6. ABB Cooling Tower Motor in New energy industry:

It is widely applied in new energy fields such as photovoltaic. For instance, ABB's high-power water-cooled series servo motors can be used in photovoltaic production equipment. With their precise control and response, they help enhance production efficiency. Meanwhile, their high efficiency and energy-saving features also meet the development needs of the new energy industry.

Our Services of ABB Cooling Tower Motor

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.