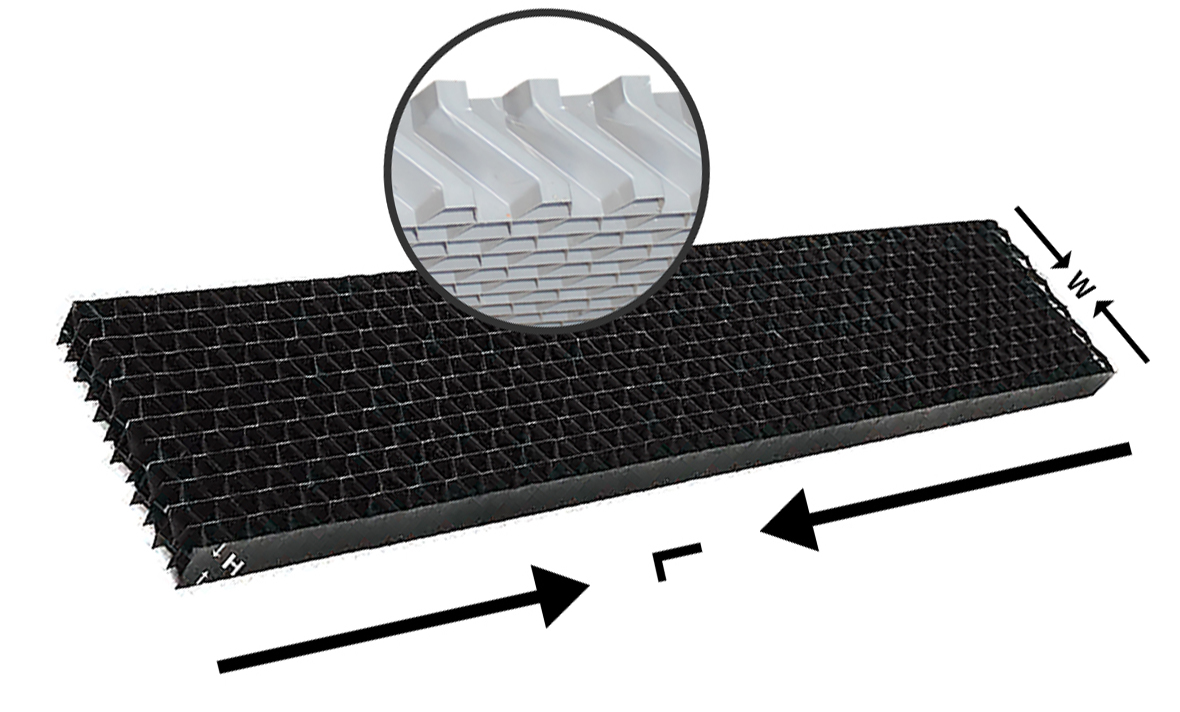

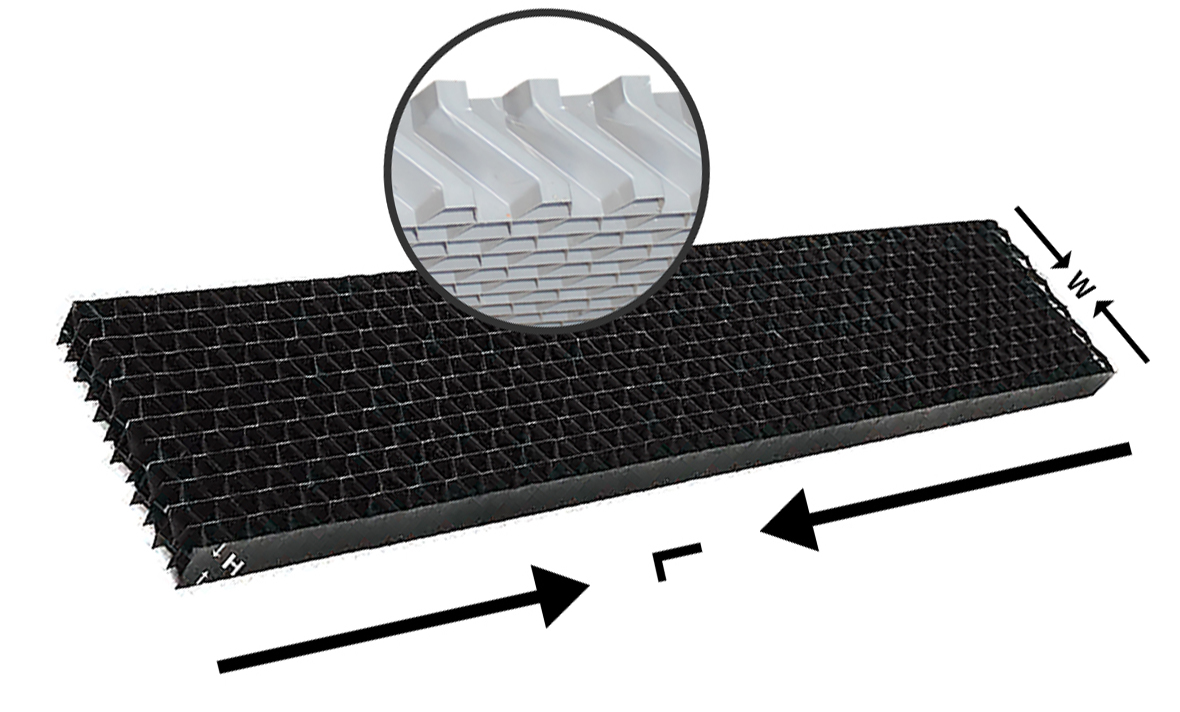

The Cooling Tower Air Inlet Louvers is made of high-strength PVC board and bonded. Advanced honeycomb grille design can improve the airflow into the cooling tower, effectively filter impurities and prevent water splashing.

When To Replace Cooling Tower Air Inlet Louvers

The timing for replacing the cooling tower intake louver usually depends on its degree of damage, usage environment, and maintenance conditions. Here are some situations when the cooling tower intake louver needs to be replaced:

1. Cooling Tower Air Inlet Louvers Damage or Deformation

If the Cooling Tower Air Inlet Louvers shows obvious damage, such as cracks, deformation, or missing parts, it will affect its normal functions, like blocking debris and guiding airflow. It should be replaced promptly.

If the blades or frame of the Cooling Tower Air Inlet Louvers are corroded or aged to the point where the structure is unstable, replacement is also necessary.

2. Cooling Tower Air Inlet Louvers Blockage or Scaling

After long-term use, the Cooling Tower Air Inlet Louvers may be clogged by dust, debris, or scale, leading to poor ventilation and reduced cooling efficiency of the cooling tower. If cleaning does not restore its performance, replacement should be considered.

During winter operation, if the Cooling Tower Air Inlet Louvers becomes frozen due to low temperatures, causing ventilation blockage or damage, it needs to be replaced.

3. Cooling Tower Air Inlet Louvers Maintenance Cycle

Although there is no fixed replacement cycle, it is recommended to check the condition of the Cooling Tower Air Inlet Louvers during the regular maintenance of the cooling tower. Generally, if other components of the cooling tower (such as packing) need to be replaced, the Cooling Tower Air Inlet Louvers should also be checked to see if it needs replacement.

4. Cooling Tower Air Inlet Louvers Impact on Cooling Effectiveness

If the angle, number of blades, or positioning of the Cooling Tower Air Inlet Louvers is not appropriate, causing the air to not flow evenly towards the cooling coils, or placing the cooling coils in a vortex area, which affects cooling effectiveness, replacement should be considered.

5. Cooling Tower Air Inlet Louvers Other Situations

If the material of the Cooling Tower Air Inlet Louvers is not suitable for the usage environment, for example, using a common material in a highly corrosive environment, which may accelerate aging, it should be replaced with a more corrosion-resistant material.

In summary, regularly inspecting the condition of the intake louver and replacing it in a timely manner according to the actual situation can effectively extend the service life of the cooling tower and maintain its good operating condition.

Cooling Tower Air Inlet Louvers Specification

The water collector removes the small water droplets carried in the waste gas. If they are allowed to escape through the top of the tower together with the heated air, the harm and health problems will be minimized. The drift eliminator is designed to create a tortuous path for air flow. When the water drops pass through them, they are forced to change direction, hit the side wall of the drift eliminator, aggregate and discharge back to the wet section of the cooling tower.

| W | H | L | Gap | Angle |

| 25 multiple | 65 | Any | 25 | 90° |

Cooling Tower Air Inlet Louvers Features

Features of Cooling Tower Air Inlet Louvers

Cooling Tower Air Inlet Louvers play a crucial role in the overall performance and efficiency of cooling towers. They are designed to control and optimize airflow while providing additional benefits. Here are the key features of cooling tower inlet louvers:

1. Cooling Tower Air Inlet Louvers Airflow Management

-

Function: Inlet louvers are engineered to direct and control the incoming air flow into the cooling tower. They help to ensure that air enters the tower at the desired velocity and direction, which is critical for effective heat transfer.

-

Benefit: Proper airflow management enhances the cooling efficiency of the tower by maximizing the contact between air and water, thereby improving heat dissipation.

2. Cooling Tower Air Inlet Louvers Drift Elimination

-

Function: Inlet louvers often incorporate designs that help reduce the amount of water droplets (drift) carried out of the cooling tower by the air stream.

-

Benefit: Minimizing drift reduces water loss and prevents the spread of waterborne contaminants, which is essential for maintaining water quality and reducing environmental impact.

3. Cooling Tower Air Inlet Louvers Noise Reduction

-

Function: Some inlet louvers are designed with sound attenuation features to reduce the noise generated by the airflow and the operation of the cooling tower fans.

-

Benefit: Lower noise levels create a more pleasant environment for nearby workers and residents, and may help comply with local noise regulations.

4. Cooling Tower Air Inlet Louvers Durability and Corrosion Resistance

-

Function: Inlet louvers are typically made from materials such as fiberglass reinforced plastic (FRP) or high-quality aluminum, which are resistant to corrosion and UV degradation.

-

Benefit: These materials ensure that the louvers can withstand harsh environmental conditions and long-term exposure to moisture, maintaining their structural integrity and performance over time.

5. Cooling Tower Air Inlet Louvers Customizable Design

-

Function: Cooling Tower Air Inlet Louvers can be customized to fit specific cooling tower designs and operational requirements. They can be tailored in terms of size, shape, and angle to optimize airflow characteristics for different tower configurations.

-

Benefit: Customization allows for optimal performance and integration with the cooling tower system, ensuring that the Cooling Tower Air Inlet Louvers enhance efficiency without compromising the overall design.

6. Cooling Tower Air Inlet Louvers Energy Efficiency

-

Function: By optimizing airflow, Cooling Tower Air Inlet Louvers can reduce the energy required to operate the cooling tower fans. Efficient airflow management means that the fans do not need to work as hard to achieve the desired cooling effect.

-

Benefit: Lower energy consumption translates to reduced operational costs and a smaller environmental footprint, making the cooling tower more sustainable.

7. Cooling Tower Air Inlet Louvers Aesthetic Integration

-

Function: Cooling Tower Air Inlet Louvers can be designed to match the architectural aesthetics of the surrounding environment. They can be painted or textured to blend seamlessly with the cooling tower structure and adjacent buildings.

-

Benefit: Aesthetic integration enhances the visual appeal of the cooling tower, making it more acceptable in urban or industrial settings where appearance is important.

Cooling Tower Air Inlet Louvers Conclusion

Cooling Tower Air Inlet Louvers are essential components that contribute significantly to the efficiency, durability, and overall performance of cooling towers. Their ability to manage airflow, reduce drift and noise, resist corrosion, and enhance energy efficiency makes them a vital part of modern cooling tower systems.The choice of material for inlet louvers depends on several factors, including the specific requirements of the cooling tower, environmental conditions, budget constraints, and desired performance characteristics. Fiberglass Reinforced Plastic (FRP) and aluminum are among the most popular choices due to their durability and corrosion resistance, while PVC and HDPE offer cost-effective alternatives for certain applications. Inlet louvers for cooling towers are typically designed to withstand harsh environmental conditions, including exposure to moisture, UV radiation, and corrosive elements. As a result, they are often made from materials that offer durability, corrosion resistance, and long-term reliability.

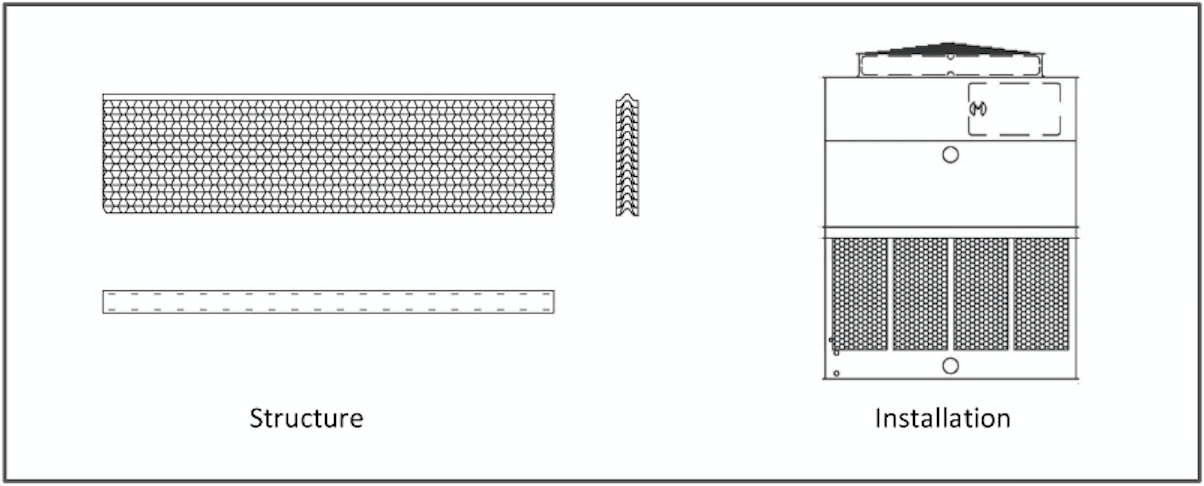

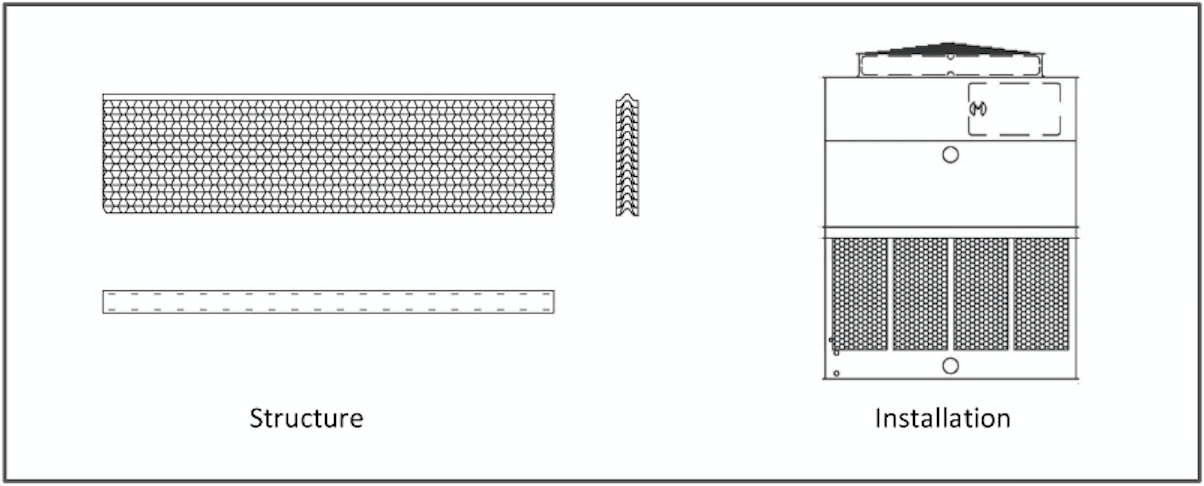

Cooling Tower Air Inlet Louvers Structural installation drawing

The structural position of the Air Inlet Louvers Cooling Tower is shown in the following figure.

Please tell us the model or size of the cooling tower, and we will estimate the number of sheets needed to replace the cooling tower.

Cooling Tower Air Inlet Louvers Application

The application range of Cooling Tower Air Inlet Louvers is: Industrial water cooling,Air compressor, Aluminum profile processing, Steam turbine, Power generation, Tannery, Electric furnace, Freezing Series, Air conditioning cooling system

Cooling Tower Air Inlet Louvers Shippment

Cooling Tower Air Inlet Louvers Packing:

Wooden,cartons,custom package

Cooling Tower Air Inlet Louvers Delivery time:

With in 10 days.

Our Services Of Cooling Tower Air Inlet Louvers

-Pre-sale services of Cooling Tower Air Inlet Louvers

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services of Cooling Tower Air Inlet Louvers

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services of Cooling Tower Air Inlet Louvers

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.