Nylon tie for cooling tower is made of high temperature resistant and UV resistant reinforced nylon 66, which has excellent aging resistance, corrosion resistance, acid and alkali resistance, and is suitable for high temperature, high humidity and chemical corrosive environment. Its high strength and toughness can withstand strong winds, vibrations, and long-term sun exposure, ensuring stable fixation of components such as pipes, cables, and packing supports in the cooling tower system.

ABS Cooling Tower Nylon Rope Knot Feature

1. Efficient heat exchange performance

Optimize surface area design: Adopt corrugated, honeycomb or grid structures to significantly increase the contact area between water and gas, and improve evaporative cooling efficiency.

Uniform water distribution: Ensure even water flow distribution, avoid the formation of dry areas, and improve heat exchange efficiency by 20% -30% compared to traditional fillers.

2. High temperature resistance and aging resistance

Material stability: Made of high-quality PVC, PP or CPVC material, it can withstand high temperature hot water of 60-80 ℃ for a long time without deformation or softening.

UV resistance: Some fillers are added with antioxidants, suitable for outdoor cooling towers, extending their service life to 8-10 years.

3. Corrosion resistance

Chemical corrosion resistance: suitable for circulating water containing chloride ions and acid bases (such as chemical plants and seawater cooling), PVC/PP material can withstand pH values ranging from 2 to 12.

Anti biological attachment: Smooth surface treatment to reduce the growth of algae and microorganisms, and lower cleaning frequency.

4. Low resistance design

Aerodynamic optimization: Special ripple angles (such as 60 ° oblique angle) reduce wind resistance and reduce fan energy consumption by 10% -15%.

Water conservation and emission reduction: Efficient evaporative cooling can reduce the amount of makeup water, which meets environmental protection requirements.

5. Modular structure

Flexible assembly: Standard modules (such as 500 × 500mm) support quick assembly and can adapt to different tower types (counter current/cross current).

Easy to maintain: Damaged modules can be partially replaced without the need for overall disassembly, reducing maintenance costs.

6. Fireproof and flame retardant performance

7. Anti clogging design

Large channel structure: Wide channels (such as 50mm spacing) reduce impurity accumulation and adapt to high turbidity water quality.

Self cleaning feature: It is not easy to accumulate dirt under the action of water flow erosion, and can maintain efficient operation for a long time.

8. Lightweight and High Strength

9. Environmental compliance

Non toxic material: Compliant with international environmental standards such as RoHS and REACH, with no risk of heavy metal precipitation.

Recyclable: After being scrapped, PVC/PP materials can be crushed and recycled to reduce waste.

10. Economic advantages

Long life cycle: The replacement cycle of high-quality fillers can reach 8-10 years, and the overall cost is lower than traditional wooden or metal fillers.

Energy saving benefits: Efficient design can reduce the energy consumption of fans/pumps, and the investment cost can be recovered within 1-2 years.

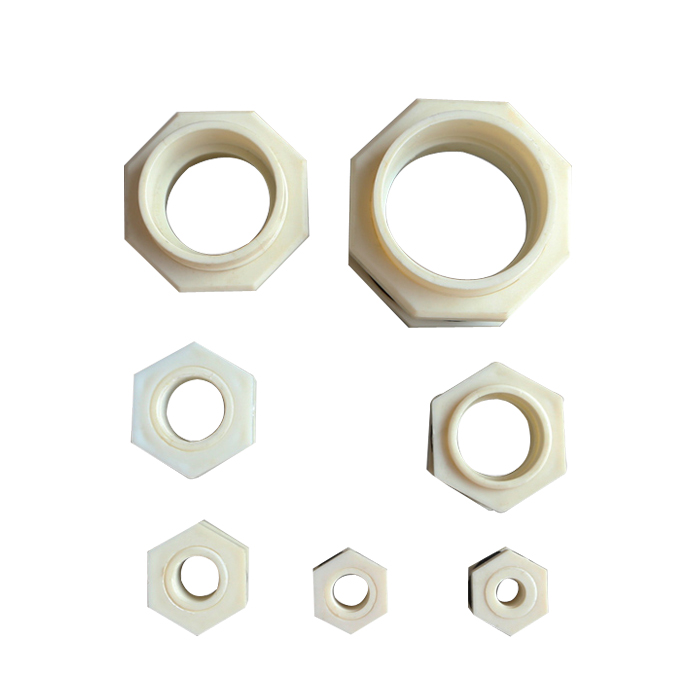

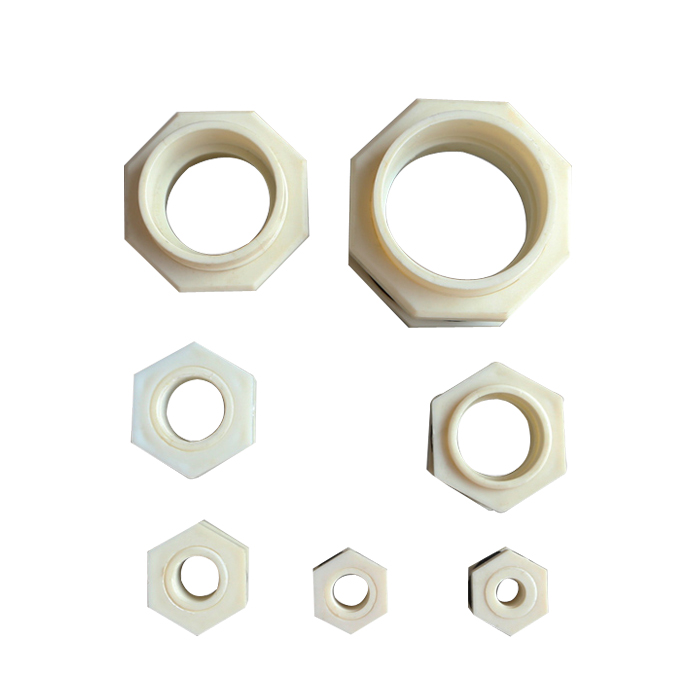

ABS Cooling Tower Nylon Rope Knot Parameter

| Model | Size | Material |

| ASJ-5 | 0.5'' | ABS |

| ASJ-75 | 0.75'' |

| ASJ-100 | 1'' |

| ASJ-150 | 1.5'' |

| ASJ-200 | 2'' |

| ASJ-300 | 3'' |

| ASJ-400 | 4'' |

ABS Cooling Tower Nylon Rope Knot Specification

ABS Cooling Tower Nylon Rope Knot Installation Steps and Precautions

1. Choose the appropriate specifications: Based on the diameter and load-bearing requirements of the tied object, select the corresponding length and width of nylon cable ties (such as heavy-duty cable ties that need

to be used for stressed areas).

2. Surrounding fixation: Wrap the cable tie around the cable, pipe, or bracket that needs to be fixed, ensuring complete wrapping and no looseness.

3. Tighten the lock buckle: Insert the knot head into the tooth groove and tighten it firmly. If you hear a "click" sound, it means it is locked.

4. Cut off excess parts: Use diagonal pliers to cut off excess zip ties at the tail to avoid scratching personnel or affecting aesthetics.

5. Check and confirm: whether the pull test is stable and ensures no risk of slipping.

1. Environmental adaptation: Temperature resistant cable ties should be used in high temperature areas (such as environments above 120 ℃) to avoid softening failure.

2. Avoid being too tight or too loose: Being too tight may damage the cable sheath, while being too loose will prevent effective fixation and requires moderate tightening.

3. Anti UV aging: Long term outdoor use should choose UV resistant models or add protective sleeves to extend their lifespan.

4. Prohibition of repeated use: Ordinary self-locking cable ties cannot be reused after being cut, and new cable ties need to be replaced (except for detachable ones).

ABS Cooling Tower Nylon Rope Knot Application

Nylon cable ties are widely used in industrial, construction, home, and electrical fields, mainly for tying and fixing. In the cooling tower, cables, pipelines, and packing supports can be securely tied, with high temperature and corrosion resistance; In power engineering, it is used to organize cables, insulate and prevent moisture; In construction projects, fixing steel bars, scaffolding, and ventilation ducts; In home life, organizing wires, gardening and tying branches, etc. Its high strength, weather resistance, and convenient self-locking design make it an ideal choice to replace traditional ropes and wires, suitable for a variety of complex environments, and provide efficient and reliable fastening solutions.

1、 Core application of cooling tower system

(1) Cable system management

Main power cord binding: flame retardant nylon ties (UL94 V-2 standard) are used to fix the power supply cables of cooling tower motor and water pump to prevent the interface from loosening due to vibration

Arrangement of sensor lines: bundle monitoring lines such as temperature and water level, with a spacing of 15-20cm and a standard arrangement

Auxiliary fixation of cable tray: used with cable tray, reinforced once every 50cm

(2) Piping system fixing

Bundling of water injection pipeline: support auxiliary fixation of PVC pipeline below DN50

Reinforcement of steam pipe insulation layer: fix insulation cotton with aluminum foil tape

Water distribution system pipeline: spray branch pipe spacing positioning

(3) Reinforcement of structural members

Packing layer support frame: cross binding reinforcement, spacing ≤ 80cm

Fan blade protective net: stainless steel core nylon knot is used for edge fixation

Maintenance platform guardrail: temporary safety rope fixing point

2、 Special environment application scheme

(1) High temperature area

(2) Chemical corrosive environment

(3) Long term outdoor exposure

3、 Installation process specification

Ordinary cable: 3-5kg pull

Fixing of structural parts: 8-10kg tensile force

Key bearing parts: 72 hour stress test is required

Horizontal pipes: one group per 60cm

Vertical cable: one group per 40cm

Vibrating parts: densified to every 30cm

The key nodes are designed with "double ties+safety buckles"

Keep the end more than 5cm from slipping off

4、 Key points of maintenance management

(1) Regular inspection

Check the tension status once a month

Replace the knots in the areas with strong ultraviolet radiation Quarterly

Complete replacement during annual overhaul

(2) Failure warning

The tooth mark slips more than 3 tooth positions

Obvious pulverization cracks appear on the surface

Color fades more than 50%

(3) Replacement standard

General environment: 3-year mandatory replacement

High temperature area: 1 year replacement cycle

Chemical corrosion area: 6-month inspection and replacement

5、 Application of technological innovation

Intelligent monitoring type: built in RFID tag records installation time and location

Discoloration warning type: automatic discoloration warning when contacting with acid and alkali substances

Self adjusting type: automatic tightening with temperature change

Note: the specific type selection needs to be configured according to the cooling tower model (countercurrent/crossflow), treatment medium (clean water/waste water/corrosive liquid) and environmental grade (C1-C5). It is suggested to establish the use archives of the cable ties to realize the full life cycle management.

ABS Cooling Tower Nylon Rope Knot Shippment

Packing:

Wooden,cartons,custom package.

Delivery time:

With in 10 days.

Our Services Of ABS Cooling Tower Water Nylon Rope Knot

-Pre-sale services

Based on the clients' requirements, we will offer product pictures, videos, quotation,information,

engineering drawings until you satisfied with it. Warmly welcome to visit our factory.

-Sale services

1 Providing production schedule photos to ensure you know every process.

2 Our experienced technician are available on the phone also internet, the clients can get instance

guidance by telephone,email, online service anytime, anywhere.

3 Also can arrange experienced technician to clients site for installation guidance, commissioning and training etc.

-After-sale services

Normally, the equipment warranty is 12 months since installation. We will keep in touch with our clients

to follow up the working condition of our machines, and offer support for maintenance.

Why choose us?

1. Highest quality

We are the manufacturer who adopts import raw materials. It is cheap price and guaranteed quality.

2. Most competitive price

We can adjustment the price according to your market demand’s changes,and also can launch a series of promotional activities in a bad economic environment.

3. Professional

We are specialized in producing and sells as development, methods and handling. We have 16 years experience.

4. Best service

Answering emails and solving questions timely. Delivery and update information on time.

Trust, good quality and service are the basic of long term business.